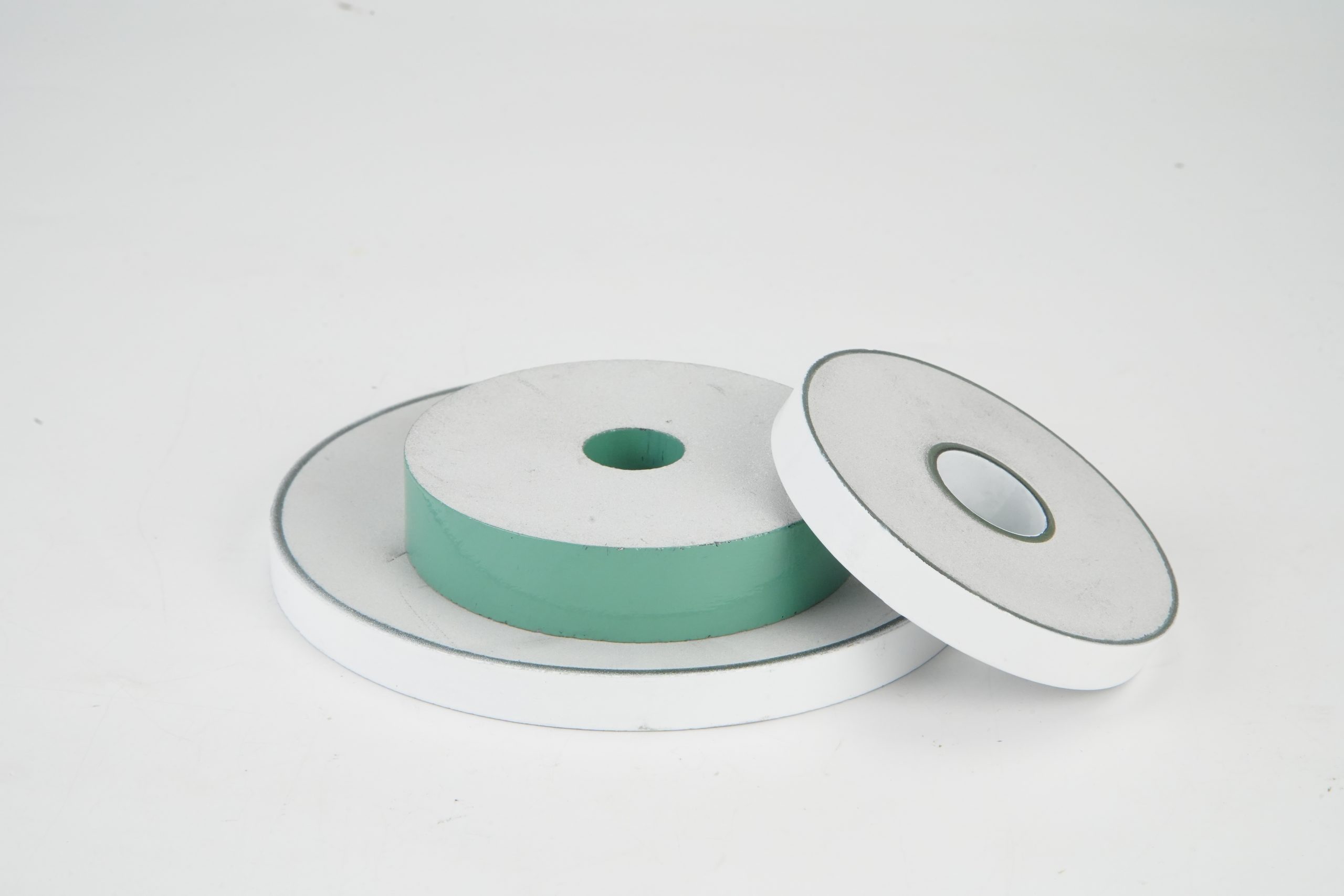

The PCB energy absorption resistor is a specialized component designed for high-frequency applications. It is made from inorganic materials such as graphite and Al₂O₃, which are sintered at high temperatures to form a solid core. The resistive element uses a semiconductor mechanism, ensuring low inductance suitable for high-frequency use. The surface is encapsulated with epoxy resin, providing excellent moisture resistance and sealing properties. This resistor can absorb random strong pulse energy release within a short time, making it ideal for applications such as power transmission, electric traction, pulse power sources, and induction heating.

Technical Features

Low Inductance : Suitable for high-frequency applications with negligible parasitic inductance.

PCB Plug-in Design : Easy installation and integration into printed circuit boards.

Compact Size : Space-saving design for efficient board layout.

High Pulse Load Capacity : Capable of handling large transient energy spikes.

Physical Technical Parameters and Dimensions

- Encapsulation : High-temperature epoxy resin coating ensures a smooth, hard surface with good appearance. Over long-term operation at temperatures above 150°C, the surface coating may undergo minor decomposition or color changes, but this will not affect the resistance performance.

- Terminals : The resistor terminals are treated with tin plating on the end face, followed by high-temperature soldering with brass-plated copper leads, ensuring excellent electrical performance.

- Soldering : The terminals feature a spring design, with each resistor fixed at four points. This design simplifies PCB assembly and provides stable connections. Recommended mounting hole diameters are 2mm to 3mm. Solder with a melting point below 230°C is recommended for optimal results.