In the world of precision manufacturing, EDM electrodes play a pivotal role in shaping hard-to-machine materials through electrical discharge machining (EDM). Traditional options like graphite or copper have served well, but they often fall short in demanding applications requiring extreme durability and efficiency. Enter 10⁻⁷ Ω·m conductive silicon carbide (SiC) ceramic—a game-changer for EDM electrodes. With its ultra-low electrical resistivity, this advanced material combines the thermal resilience of ceramics with metal-like conductivity, making it perfect for high-performance EDM processes. In this blog, we’ll explore why this SiC variant stands out, backed by recent research and industry insights as of November 2025.

Understanding EDM Electrodes and the Need for Innovation

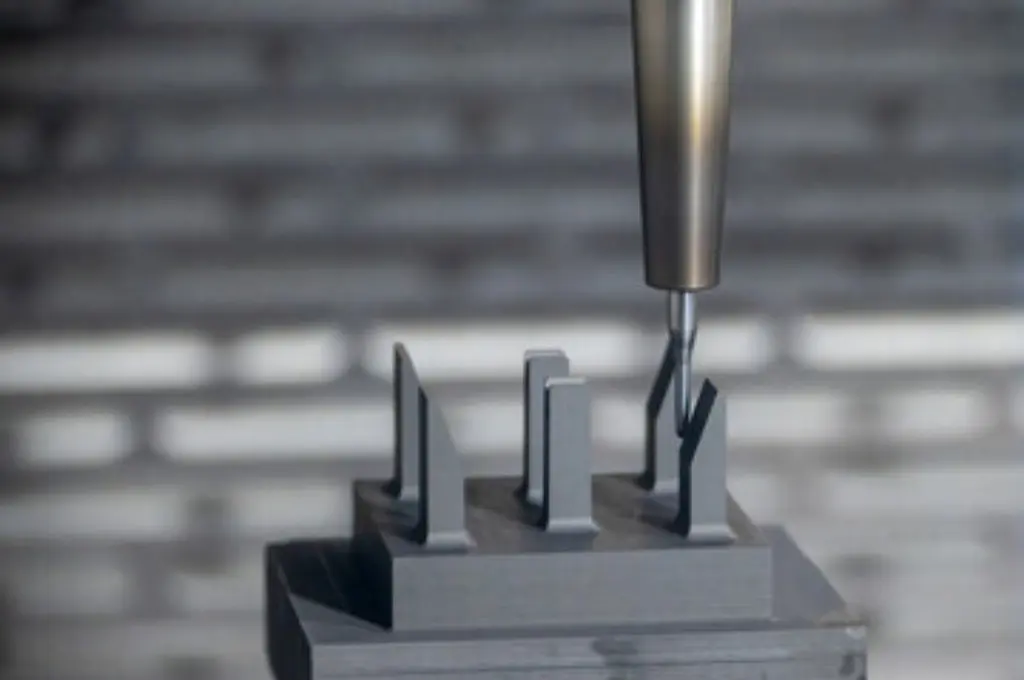

EDM electrodes are the unsung heroes of non-contact machining, generating controlled sparks to erode workpiece material without mechanical force. This makes EDM ideal for intricate molds, aerospace components, and semiconductor parts. However, challenges like electrode wear, thermal instability, and inconsistent sparking plague conventional materials. Graphite electrodes, for instance, erode quickly in high-energy discharges, while copper deforms under heat.

Conductive SiC Ceramic

Conductive SiC Ceramic

Here’s where conductive SiC shines. Silicon carbide, a covalent ceramic known for its hardness (Mohs 9.5) and thermal conductivity (>100 W/m·K), traditionally boasts high resistivity (10³–10⁵ Ω·cm), rendering it non-conductive for EDM. But through advanced doping—like carbon addition up to 13 wt.%—researchers have slashed resistivity to as low as 9.1 × 10⁻² Ω·cm (or ~10⁻⁴ Ω·m), and innovative formulations push it further to 10⁻⁷ Ω·m.This breakthrough transforms SiC from an EDM workpiece into a superior EDM electrode material, enabling efficient spark generation while retaining ceramic advantages.

The Unique Properties of 10⁻⁷ Ω·m SiC Ceramic

At the heart of its suitability is the resistivity sweet spot: 10⁻⁷ Ω·m. This value—comparable to metals like copper (1.7 × 10⁻⁸ Ω·m)—ensures low-voltage sparking thresholds, crucial for micro-EDM (μEDM) where precision is paramount. Unlike semi-conductive SiC variants that require high sparking power due to elevated resistivity, this ultra-conductive form initiates discharges reliably at 110–150 V, minimizing energy waste and heat buildup.

SiC’s atomic structure further amplifies its prowess. Its strong Si-C bonds deliver exceptional thermal shock resistance (up to 1400°C) and oxidation stability, preventing the electrode degradation seen in metal-based EDM electrodes. Add in a Young’s modulus >400 GPa for rigidity and low thermal expansion (4 × 10⁻⁶/K), and you have a material that maintains shape integrity during prolonged runs.

Performance Advantages: Efficiency and Precision Redefined

When used as EDM electrodes, 10⁻⁷ Ω·m SiC ceramics deliver measurable gains. Studies on reaction-bonded SiC (SiSiC) drilling show material removal rates (MRR) soaring 1.2–46 times higher than with copper electrodes, thanks to optimized flushing and reduced tool wear ratio (TWR).In one 2025 experiment machining hardened D2 steel, SiC-reinforced copper composites cut TWR by 12–18%, extending electrode life and slashing downtime.

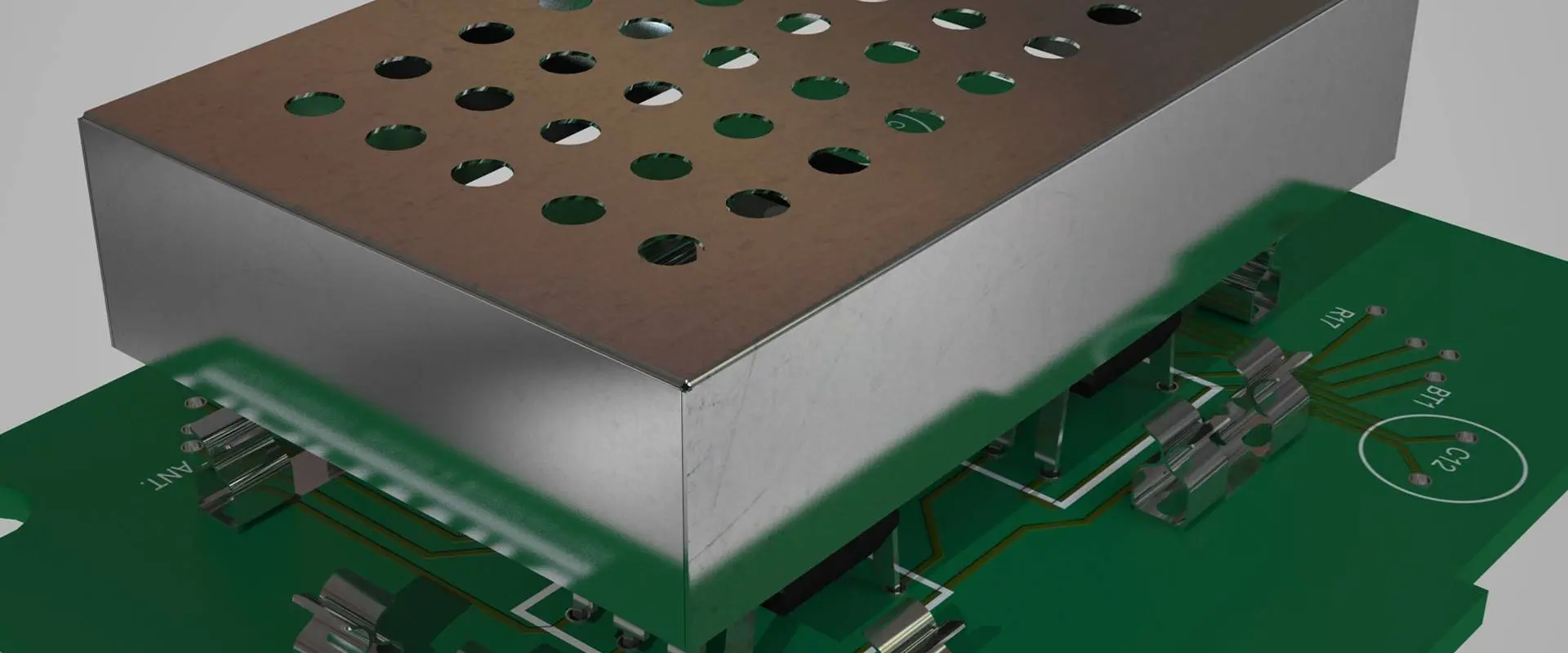

Precision is another boon. The thin recast layer and minimal heat-affected zone (HAZ) in μEDM with conductive SiC preserve workpiece integrity—vital for semiconductor wafers where tolerances are sub-micron.For wire EDM (WEDM), SiC electrodes enable slicing of tough ceramics like itself, with kerf losses under 0.1 mm and surface roughness (Ra) below 1 μm.Environmentally, it aligns with sustainable manufacturing: lower energy use and recyclable scraps mean greener operations compared to metal electrodes.

Real-World Applications in Cutting-Edge Industries

The versatility of SiC-based EDM electrodes spans high-stakes sectors. In aerospace, they machine turbine blades from Inconel or Ti alloys, enduring corrosive coolants without pitting. Semiconductor fabs leverage them for drilling micro-vias in SiC wafers, supporting 5G and EV power modules—markets projected to hit $120B by 2030. Automotive mold makers benefit from faster prototyping of EV battery housings, while medical device production uses them for biocompatible titanium implants.A 2023 Springer study on SiSiC EDM drilling underscores this: tubular electrodes with SiC tips achieved through-holes with 99% circularity, outperforming brass alternatives.

As EV adoption surges (1,800M units in 2025), demand for durable EDM electrodes in SiC component fabrication will explode.

Future Prospects: Scaling SiC for Tomorrow’s EDM

Looking ahead, advancements in spark plasma sintering (SPS) of SiC-TiB₂ composites promise even broader adoption.