When it comes to managing extreme electrical loads — from industrial motor drives to renewable energy systems and electric vehicles — traditional air-cooled resistors often fall short. Enter the liquid-cooled resistor: a high-performance, thermally optimized solution engineered for continuous, high-power energy dissipation in the most demanding environments.

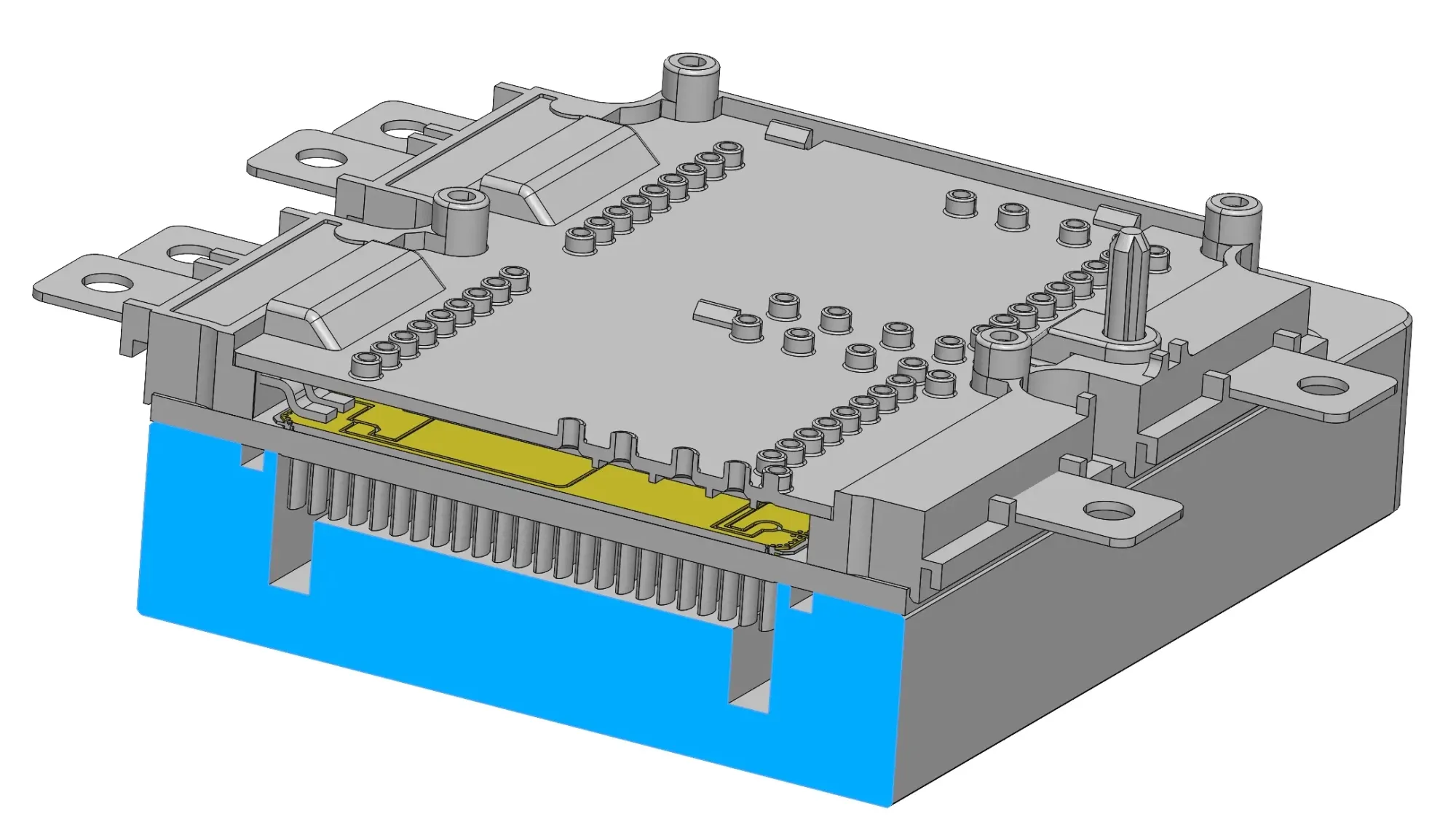

Diamond Thick-film Liquid-Cooled Power Resistor

Diamond Thick-film Liquid-Cooled Power Resistor

What Is a Liquid-Cooled Resistor?

A liquid-cooled resistor is a high-power resistor designed with integrated fluid channels that circulate coolant (typically deionized water or glycol mixtures) to efficiently remove heat. Unlike conventional resistors that rely on convection or fans, liquid cooling enables 10x higher power density, stable resistance values under load, and 24/7 operation — even at multi-kilowatt or megawatt levels.

These resistors are constructed using robust materials like NiCr (nickel-chrome) or FeCrAl (iron-chrome-aluminum) alloys, sealed within corrosion-resistant housings (often aluminum or stainless steel) with coolant flow paths. The result? A compact, reliable component that turns electrical energy into heat — and safely whisks that heat away.

10 Critical Roles of Liquid-Cooled Resistors

Thanks to their superior thermal management, liquid-cooled resistors serve a wide range of functions across industries:

- Braking Resistor Absorbs regenerative energy from large motors in elevators, cranes, trains, and EVs — preventing overvoltage and enabling smooth deceleration.

- Bleeder / Discharge Resistor Safely drains stored energy from high-voltage DC bus capacitors after shutdown, protecting technicians and equipment.

- Charging/Discharging Resistor Controls inrush current and discharge rates in battery systems, supercapacitor banks, and pulsed power applications.

- Dummy Load / Load Bank Simulates real-world electrical loads for testing generators, UPS systems, inverters, and power supplies under full stress.

- Snubber Resistor Suppresses voltage spikes and ringing in switching circuits (IGBTs, MOSFETs), extending the life of power semiconductors.

- Soft-Start Resistor Limits inrush current during power-up of heavy machinery, preventing damage to contactors, fuses, and rectifiers.

- Surge Suppression Resistor Protects systems from damaging current surges during startup or fault conditions — especially in HVDC and data center power systems.

- Power Absorption Resistor Dissipates reflected or excess power in RF amplifiers, particle accelerators, and grid-tied converters.

- Heating Element In some applications, the resistor’s heat output is intentional — used for industrial fluid heating, thermal testing, or anti-condensation systems.

- Energy Dump Resistor (General Purpose) A catch-all term for any resistor whose primary job is converting electricity into manageable heat — and liquid cooling makes it sustainable at scale.

Why Choose Liquid Cooling?

- ✅ Higher Power Density — Ideal for space-constrained cabinets or mobile platforms.

- ✅ Thermal Stability — Minimal resistance drift due to controlled temperature.

- ✅ Silent Operation — No fans = perfect for labs, hospitals, or military use.

- ✅ Long-Term Reliability — Consistent performance under continuous or cyclic loads.

- ✅ Scalability — Modular designs allow easy paralleling for MW-level systems.

Top Applications

Liquid-cooled resistors are indispensable in:

- Transportation: Electric trains, e-buses, ship propulsion

- Energy: Wind turbine converters, solar inverter testing, HVDC systems

- Industry: Steel mills, mining hoists, large servo drives

- Defense & Research: Radar systems, electromagnetic launchers, fusion experiments

- Data Centers: Testing HVDC power distribution and battery backup systems

Key Design Considerations

When integrating liquid-cooled resistors:

- Match coolant flow rate, pressure drop, and inlet temperature to resistor specs.

- Use deionized water or approved coolant to prevent corrosion and electrical leakage.

- Implement temperature and flow monitoring for fail-safe operation.

- Always power on coolant circulation BEFORE applying electrical load.

Final Thoughts

Liquid-cooled resistors aren’t just “another type of resistor” — they’re the ultimate thermal solution for systems where failure is not an option. Whether you’re designing a megawatt-scale braking system or validating a next-gen power converter, liquid cooling delivers the performance, reliability, and density you need to push the limits — safely.