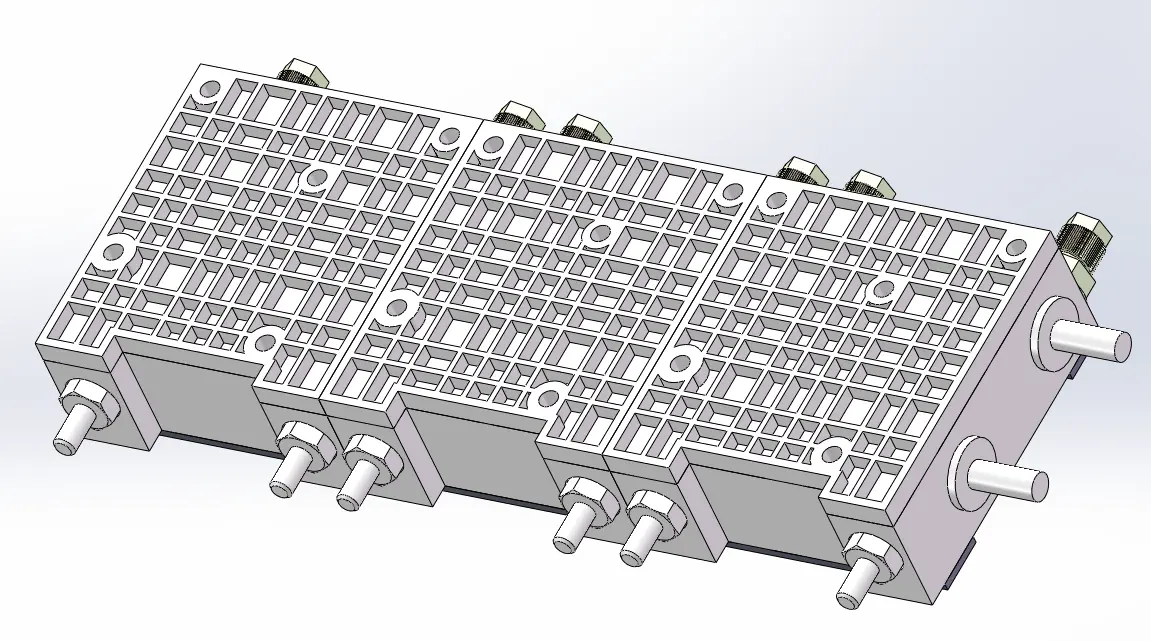

When it comes to hoisting operations, precision, safety, and efficiency are paramount. Whether you’re operating a small-scale industrial crane or a heavy-duty mining hoist, the performance of your equipment depends significantly on its electrical components. One crucial component that plays a vital role in ensuring smooth operation is the water-cooled resistor . Specifically, resistors rated at 1.5KW and 18KW are widely used in hoists to manage energy dissipation and maintain optimal system performance.

Water-Cooled Resistors

Water-Cooled Resistors

Why Water-Cooled Resistors?

Traditional air-cooled resistors can overheat under high loads, leading to inefficiencies and potential downtime. In contrast, water-cooled resistors offer superior heat dissipation capabilities, making them ideal for demanding applications like hoists. These resistors use water as a cooling medium, which effectively absorbs and transfers heat away from the resistor element. This ensures stable performance even during prolonged operation or when handling heavy loads.

For hoists, where braking energy needs to be dissipated safely, water-cooled resistors provide an efficient solution. They are particularly beneficial in scenarios where space is limited, as they occupy less room compared to their air-cooled counterparts. Additionally, their robust design makes them suitable for harsh environments, such as those found in construction sites, ports, or mines.

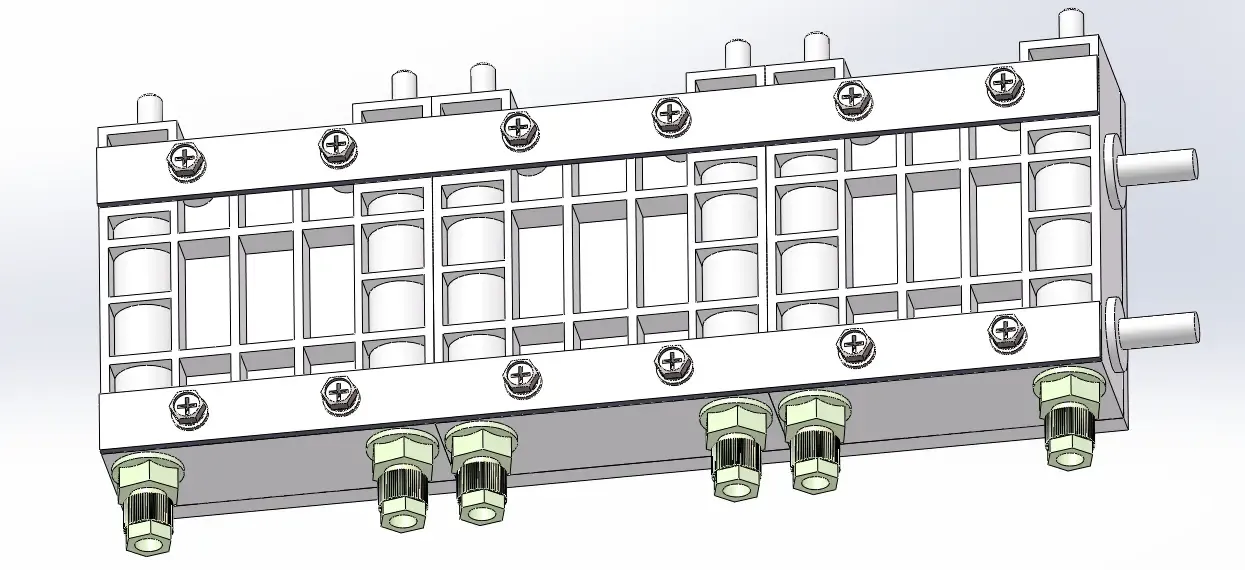

Applications of 1.5KW and 18KW Water-Cooled Resistors

The choice between a 1.5KW and 18KW water-cooled resistor depends on the specific requirements of your hoist system. Let’s explore how these two variants cater to different operational needs:

- 1.5KW Water-Cooled Resistor : This lower-power option is typically used in smaller hoists or systems with moderate load requirements. For instance, light-duty cranes in warehouses or assembly lines often rely on 1.5KW resistors for dynamic braking. These resistors ensure that excess energy generated during deceleration is safely dissipated without compromising the system’s integrity.

- 18KW Water-Cooled Resistor : On the other hand, larger hoists designed for heavy lifting require more powerful resistors. An 18KW water-cooled resistor is capable of handling substantial braking energy, making it suitable for applications like shipyard cranes, offshore drilling rigs, or large-scale mining hoists. Its higher capacity ensures reliable performance under extreme conditions, preventing overheating and extending the lifespan of the equipment.

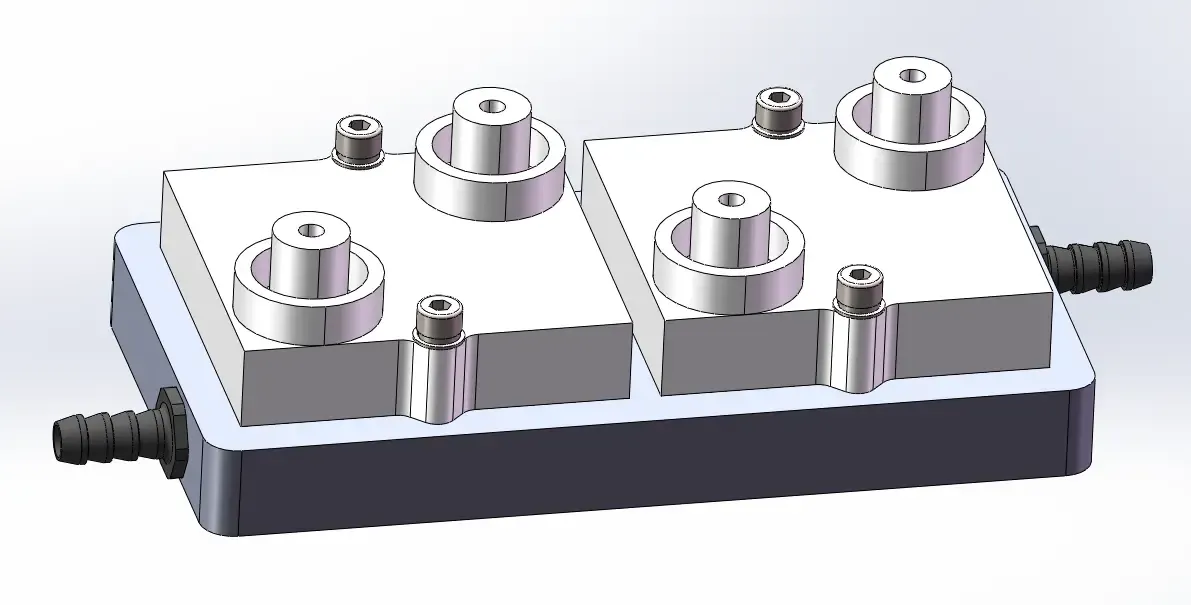

Key Benefits of Using Water-Cooled Resistors in Hoists

- Enhanced Safety : By efficiently dissipating braking energy, water-cooled resistors reduce the risk of overheating and thermal damage, ensuring safer operations.

- Improved Efficiency : With better heat management, these resistors contribute to overall system efficiency, reducing energy losses and operational costs.

- Compact Design : Their compact size allows for easier integration into existing hoist systems, saving valuable space.

- Durability : Designed to withstand tough working conditions, water-cooled resistors are built to last, minimizing maintenance needs.

Water-Cooled Resistors

Water-Cooled Resistors

Conclusion

Incorporating water-cooled resistors into hoist systems not only enhances performance but also ensures long-term reliability. Whether you opt for a 1.5KW or 18KW variant, these resistors provide the perfect balance of power, efficiency, and durability. As industries continue to demand higher productivity and safety standards, investing in advanced technologies like water-cooled resistors becomes essential. Make sure to choose the right resistor based on your hoist’s specifications to maximize its potential and achieve seamless operations.