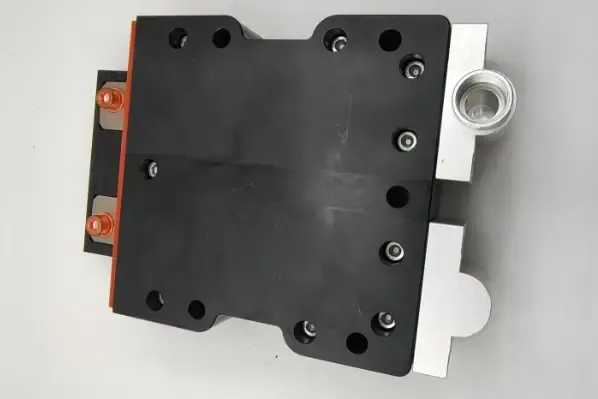

In modern High-Voltage Direct Current (HVDC) systems—especially those operating at 800V DC for electric vehicle charging, data centers, and industrial applications—efficient energy control is non-negotiable. One often-overlooked yet vital component in ensuring system stability and safety is the resistor in the Snubber circuit. When enhanced with liquid cooling, this resistor transcends its traditional role, acting not just as a simple damper but as a dynamic braking resistor and a key enabler of controlled energy dissipation in high-power environments.

What Is a Snubber Circuit—and Why Does It Matter in HVDC?

Liquid-Cooled Resistors

Liquid-Cooled Resistors

A Snubber circuit, typically composed of a resistor and capacitor (RC network), is designed to suppress voltage spikes and ringing caused by rapid switching of inductive loads—common when using IGBTs or SiC MOSFETs in 800V HVDC architectures. Without proper snubbing, these transients can damage semiconductors, cause electromagnetic interference (EMI), or destabilize the DC bus.

The resistor in the Snubber circuit plays a crucial role: it safely dissipates the energy stored in the snubber capacitor as heat. But in high-frequency or high-energy scenarios—such as during fault interruption, regenerative braking, or system testing—this resistor must handle significant thermal loads. That’s where liquid-cooled resistors come in.

Liquid-Cooled Resistors: Enabling High-Density, High-Reliability Snubbing

Traditional air-cooled Snubber resistors struggle in compact, high-power 800V HVDC systems due to limited heat dissipation, large footprint, and acoustic noise. In contrast, liquid-cooled resistors integrate directly into the system’s thermal management infrastructure—often sharing coolant loops with power modules or cold plates.

This design offers three key advantages in HVDC applications:

- High Pulse Energy Absorption: Capable of absorbing joules to kilojoules of energy during DC breaker operations or sudden load dumps.

- Continuous Power Handling: Sustains hundreds of watts to kilowatts of average power in high-switching-frequency converters.

- Compact Integration: Enables dense packaging in EV fast-charging cabinets, data center HVDC racks, and industrial drives.

From Braking Resistor to Energy Management Tool

While often associated with braking in motor drives, the Snubber resistor in an 800V HVDC system functions as a controlled energy sink. During regenerative events—like when an EV decelerates or a data center server rack undergoes load shedding—the DC bus voltage can surge. The Snubber circuit, with its liquid-cooled resistor, provides a fast-acting path to clamp overvoltage and dissipate excess energy safely.

In systems where grid feedback isn’t possible (e.g., isolated microgrids or test benches), this “braking” action becomes essential for protection. Moreover, in HVDC circuit breaker testing or power converter validation, liquid-cooled Snubber resistors act as programmable dump loads, simulating real-world energy absorption scenarios without overheating.

Design Considerations for Engineers

When selecting a liquid-cooled resistor for Snubber circuits in HVDC systems, engineers should prioritize:

- Low inductance construction to avoid parasitic oscillations;

- Compatibility with dielectric or deionized cooling fluids;

- High voltage isolation (>2 kVDC) between electrical terminals and coolant channels;

- Thermal response matched to pulse duration and duty cycle.

Conclusion

In the evolving landscape of 800V HVDC technology, the humble Snubber resistor—when upgraded to a liquid-cooled design—emerges as a cornerstone of system resilience. Far more than a passive component, it enables safe braking, stabilizes switching transients, and supports scalable energy management. As power densities rise and thermal constraints tighten, integrating liquid-cooled resistors into Snubber circuits is no longer optional—it’s essential for next-generation HVDC reliability.