In today’s demanding power electronics landscape — from electric vehicles and AI data centers to renewable energy systems and 5G infrastructure — traditional air-cooled resistors are no longer sufficient. Enter liquid-cooled resistors: the next-generation thermal management solution engineered to handle extreme power densities, pulsed loads, and high-frequency stress with unmatched reliability.

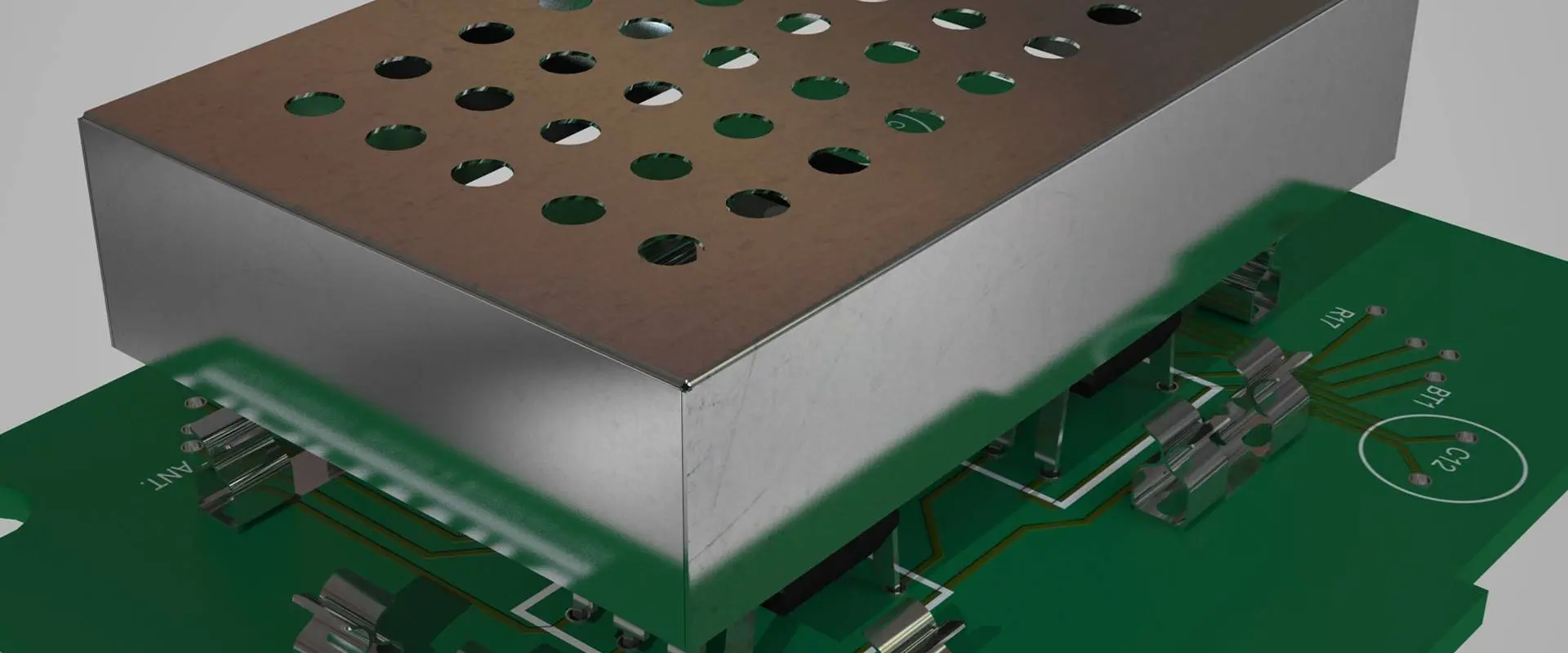

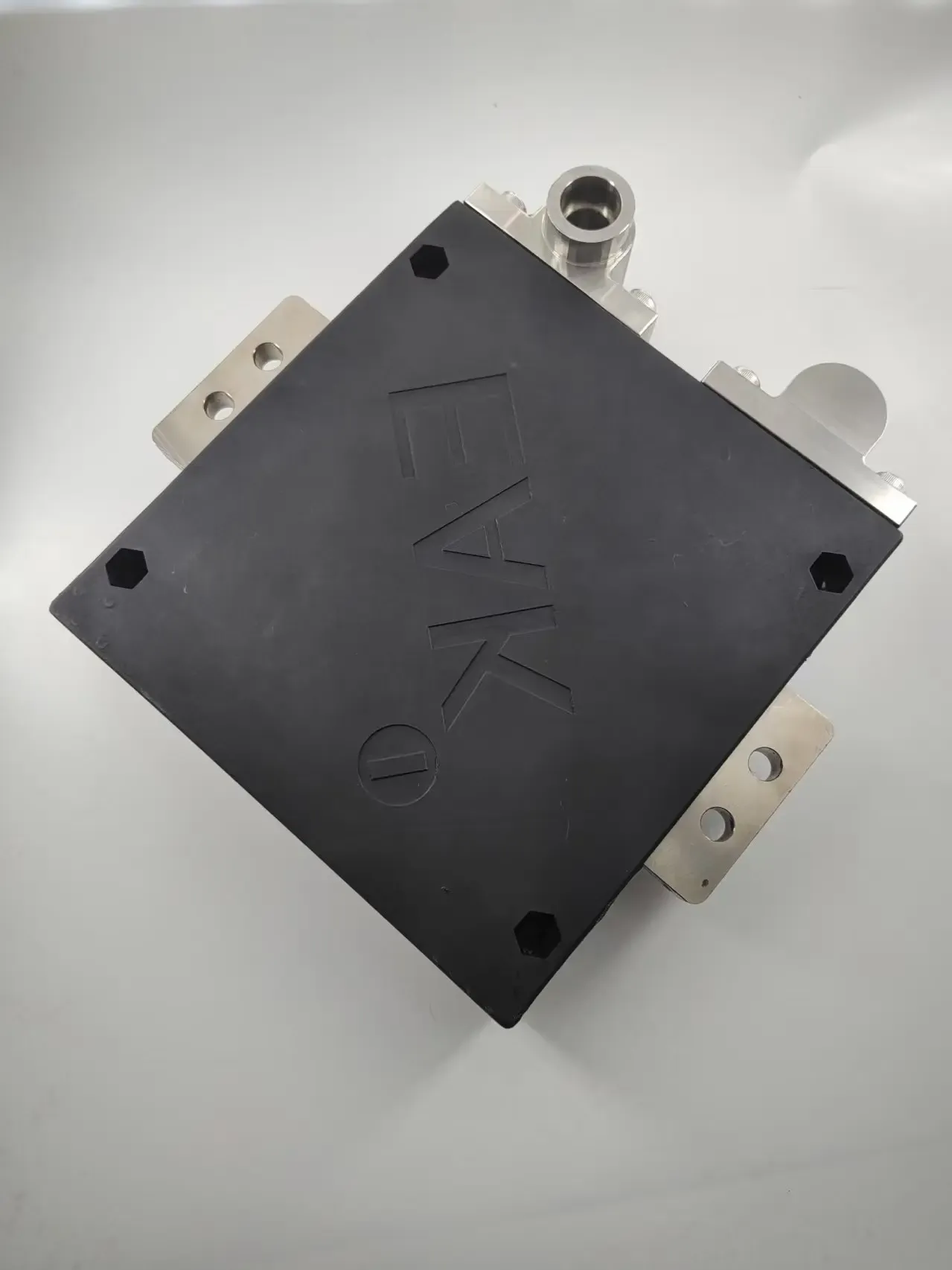

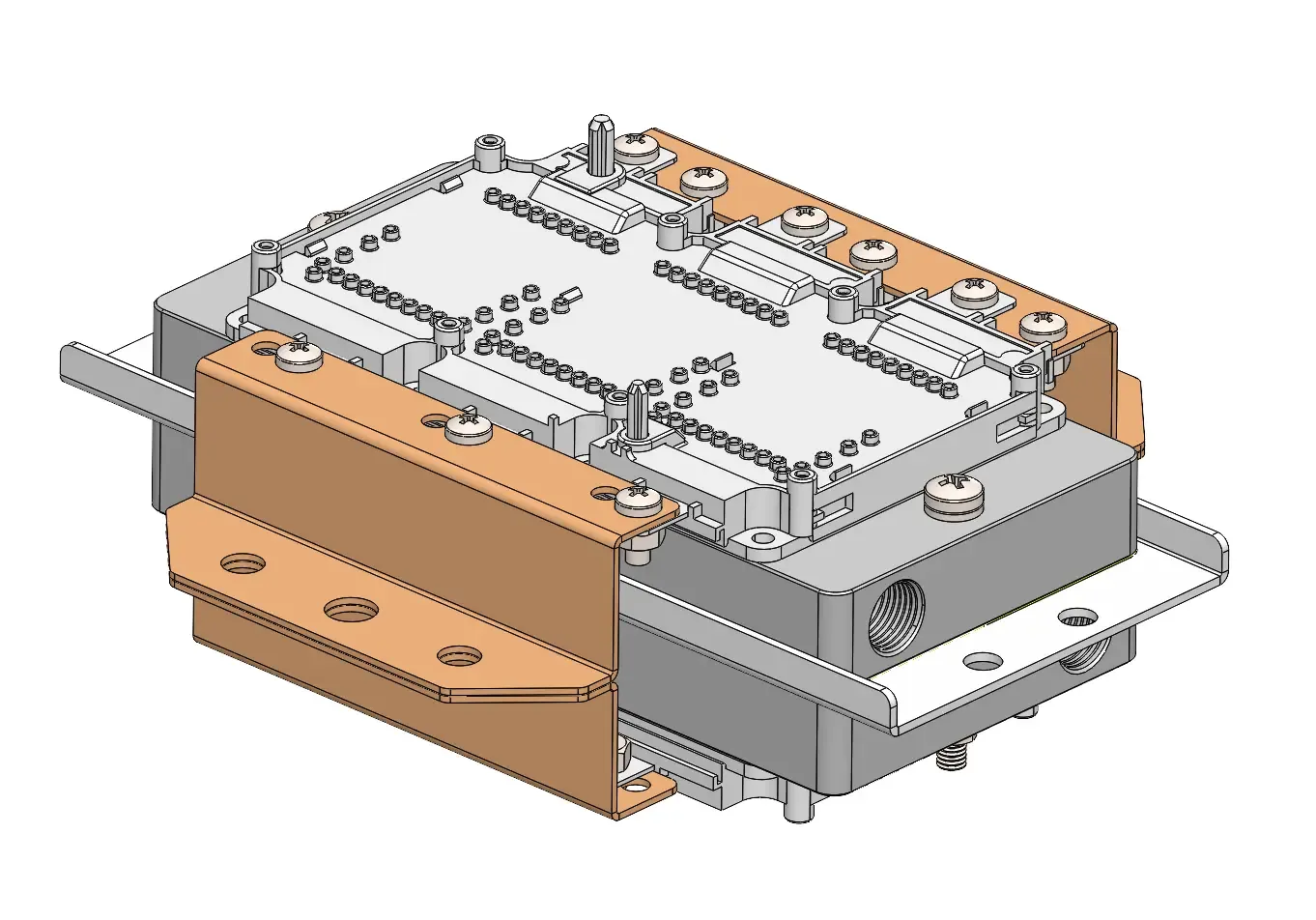

Unlike conventional resistors that rely on slow, inefficient air convection, liquid-cooled resistors use a sealed coolant loop — typically deionized water or dielectric fluid — to directly absorb and dissipate heat from the resistive element. This enables up to 5x higher power density in 60% less space, making them ideal for compact, high-performance systems where thermal runaway is not an option.

Liquid-Cooled Resistors

Liquid-Cooled Resistors

Core Applications of Liquid-Cooled Resistors

1. Braking Resistor Systems in EVs & Rail When electric vehicles or high-speed trains decelerate, regenerative braking generates massive reverse current. A liquid-cooled braking resistor safely dissipates this energy as heat, preventing DC bus overvoltage. With cooling channels integrated into the resistive core, these systems handle continuous loads up to 500 kW — far beyond the capability of air-cooled alternatives.

2. Bleeder Resistor for High-Voltage Safety In battery storage systems, UPS units, and HVDC converters, stored charge in capacitors poses serious safety risks. Liquid-cooled bleeder resistors rapidly and controllably discharge high-voltage capacitors (up to 100 kV) within seconds, ensuring compliance with IEC 62477. Their liquid cooling prevents thermal degradation during repeated discharge cycles — a critical advantage over ceramic or wirewound bleeder resistors.

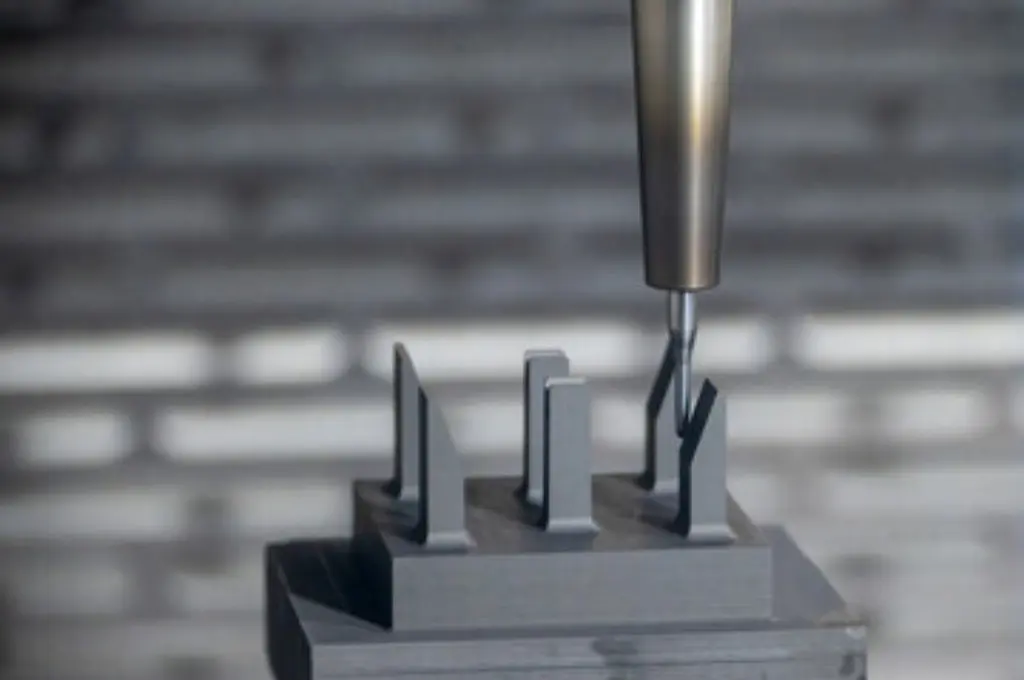

3. Pre-Charge & Inrush Current Limiting Resistors Powering up large capacitive loads causes destructive inrush currents. Liquid-cooled pre-charge resistors and surge resistors limit initial current spikes, protecting contactors and semiconductors. Advanced thick-film designs with SiC ceramic substrates withstand 1000A+ pulses and 5,000+ cycles — perfect for EV chargers and industrial inverters.

4. Pulse Load Resistors & Pulse Resistors for Laser, Radar & Medical Systems Pulsed power applications — such as pulsed lasers, particle accelerators, and radar transmitters — demand resistors that survive microsecond-scale, megawatt-level energy bursts. Liquid-cooled pulse load resistors made with SiC conductive ceramic offer ultra-low inductance, minimal parasitics, and exceptional thermal shock resistance, enabling stable performance at frequencies up to 100 kHz.

5. Snubber Resistors in High-Frequency Inverters IGBT and SiC MOSFET switching generates voltage spikes and ringing. Liquid-cooled snubber resistors integrated into RC snubber networks effectively dampen these transients. Their compact, thermally stabilized design ensures consistent performance in 50–200 kHz motor drives and solar inverters.

6. RF Liquid-Cooled Resistors & RF Load Resistors for 5G & Defense In microwave and RF systems — including 5G base stations, satellite comms, and radar jamming — RF liquid-cooled resistors absorb reflected power without overheating. Engineered with precision impedance (50Ω/75Ω) and VSWR <1.1:1, these high-frequency liquid-cooled resistors support continuous power up to 10 kW and frequencies up to 100 GHz. The integration of SIC ceramic high-power pulse resistors as the core element ensures unmatched stability under extreme RF stress.

7. Arc-Suppression & High-Voltage Resistors in Grid Protection In substations and HVDC terminals, liquid-cooled arc-suppression resistors limit fault current arcs during circuit breaker operation. Paired with high-voltage resistors rated for 35–150 kV, they ensure grid stability during transient faults — with no risk of thermal cracking or insulation failure.

Liquid-Cooled Resistors

Liquid-Cooled Resistors

Why Choose Liquid-Cooled Resistors?

- ✅ 3–5x higher power density than air-cooled

- ✅ Precise temperature control (<85°C)

- ✅ Silent operation — no fans required

- ✅ Compatible with thick-film, SiC ceramic, and high-frequency designs

- ✅ Certified for industrial, automotive, and defense standards (AEC-Q200, MIL-STD)

The Future is Liquid-Cooled As AI data centers, EVs, and renewable grids push power densities into the megawatt range, liquid-cooled resistors are no longer optional — they’re essential infrastructure. From braking resistors to RF liquid-cooled loads, and from pulse resistors to SiC ceramic high-power resistors, this technology is redefining what’s possible in high-performance electronics.