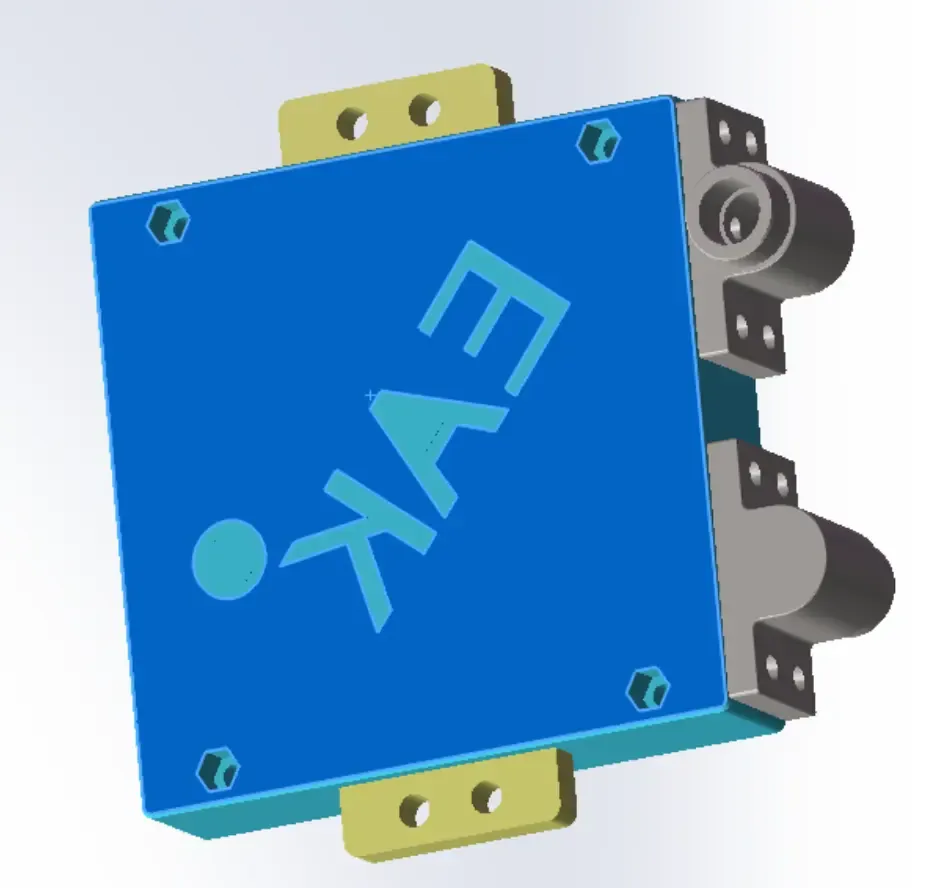

In modern industrial applications, especially those involving high-frequency operation and frequent braking cycles, the need for efficient and reliable braking solutions is critical. One such application involves the use of a liquid cooled resistor (EAK Series) to manage regenerative energy during deceleration in a frequency converter-driven Roots pump system.

25KW Liquid-Cooled Resistors

25KW Liquid-Cooled Resistors

Application Overview

The system in question utilizes a variable frequency drive (VFD) to control a Roots pump operating at frequencies ranging from 20Hz to 80Hz. The motor’s power output at 80Hz is approximately 4–5kW, while it reduces to around 3kW at 20Hz. Despite the change in frequency, the load remains constant throughout the cycle. Each full working cycle lasts 45 seconds, with a deceleration phase lasting between 10 to 15 seconds — during which the VFD must safely dissipate the excess regenerative energy produced by the motor.

To ensure safe and stable operation, a braking resistor is required to absorb the energy generated during the deceleration period. Due to the high duty cycle and significant current involved (with peak current reaching up to 48.7A), a liquid cooled resistor was selected as the optimal solution.

Why Choose a Liquid Cooled Resistor?

Standard air-cooled resistors are often insufficient for high-duty-cycle applications due to their limited thermal capacity and cooling efficiency. In contrast, liquid cooled resistors offer:

- Higher power dissipation capability

- Stable performance under continuous or cyclic loads

- Compact design with superior thermal management

- Longer service life and reliability

These features make liquid cooled resistors ideal for demanding environments like this Roots pump system, where precision, durability, and safety are paramount.

Calculating Required Power Rating

To determine the appropriate power rating for the resistor, we apply the formula:

P > E × f , Where:

- E = Single braking energy (Joules)

- f = Braking frequency (cycles per second)

Based on system parameters:

- Deceleration time: 10–15s

- Working cycle: 45s → braking occurs every 45 seconds → f ≈ 0.022 Hz

- Average braking power during deceleration: ~4kW over ~12.5s → E ≈ 4kW × 12.5s = 50,000 J

Therefore: P > 50,000 J × 0.022 Hz = 1,100 W

Considering a safety margin of 1.5–2 times, the required resistor should be capable of handling at least 1,650–2,200W continuously.

An EAK series liquid cooled resistor rated at 2,500W continuous power was selected, ensuring ample headroom for long-term reliability and peak load conditions.

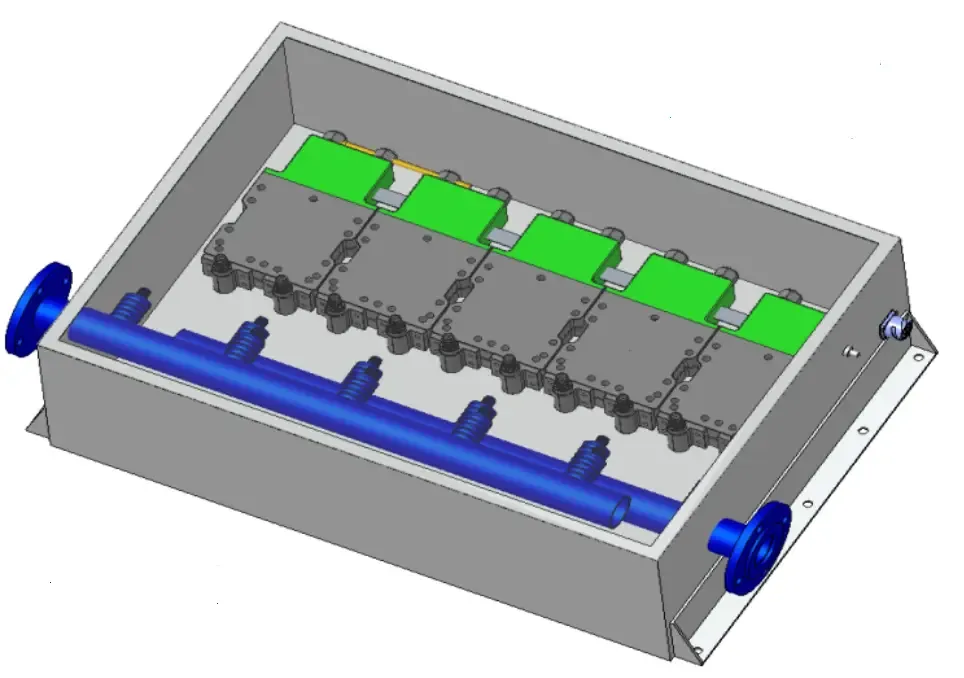

100KW Liquid Cooled Resistors

100KW Liquid Cooled Resistors

Installation and Performance

The EAK liquid cooled resistor was integrated into the DC bus of the VFD, connected via a dedicated braking chopper unit. The resistor was plumbed into an existing closed-loop cooling system using deionized water to maintain optimal operating temperatures.

Post-installation monitoring showed:

- Stable bus voltage during deceleration

- No overheating or derating events

- Consistent braking performance across all cycles

- Reduced stress on the VFD components

Conclusion

This case demonstrates the effectiveness of liquid cooled resistors in managing regenerative energy in high-performance industrial systems. By choosing the right resistor — one that meets both the energy absorption and power dissipation requirements — the system achieved enhanced reliability, reduced downtime, and improved overall efficiency.

For engineers and system designers facing similar challenges, the EAK series liquid cooled resistor offers a proven, scalable solution for VFD braking applications — especially in environments with high-frequency cycling and heavy regenerative loads.