In high-voltage electrical systems—especially those operating at 10 kV or above—safety, reliability, and rapid energy dissipation are non-negotiable. One of the most critical yet often overlooked components in such setups is the capacitor discharge resistor. Designed to safely bleed off stored energy after system shutdown, these resistors protect personnel, equipment, and downstream electronics from dangerous residual voltages. But not just any resistor will do. At 10 kV, engineers need non-inductive, high-energy, high-voltage-rated resistors engineered for extreme transient conditions.

High-Voltage Capacitor Discharge Resistors

High-Voltage Capacitor Discharge Resistors

Why Standard Resistors Fail at 10 kV

A typical 10 kV capacitor bank can store hundreds or even thousands of joules of energy. If disconnected from the circuit without a proper discharge path, this energy remains trapped—posing lethal shock hazards and risking arc flashes during maintenance. Standard wirewound or film resistors often exhibit parasitic inductance, which slows discharge, causes voltage ringing, and may even lead to insulation breakdown. Moreover, they lack the thermal mass to absorb large energy pulses without cracking, drifting, or failing catastrophically.

The Ideal Discharge Resistor for 10 kV Applications

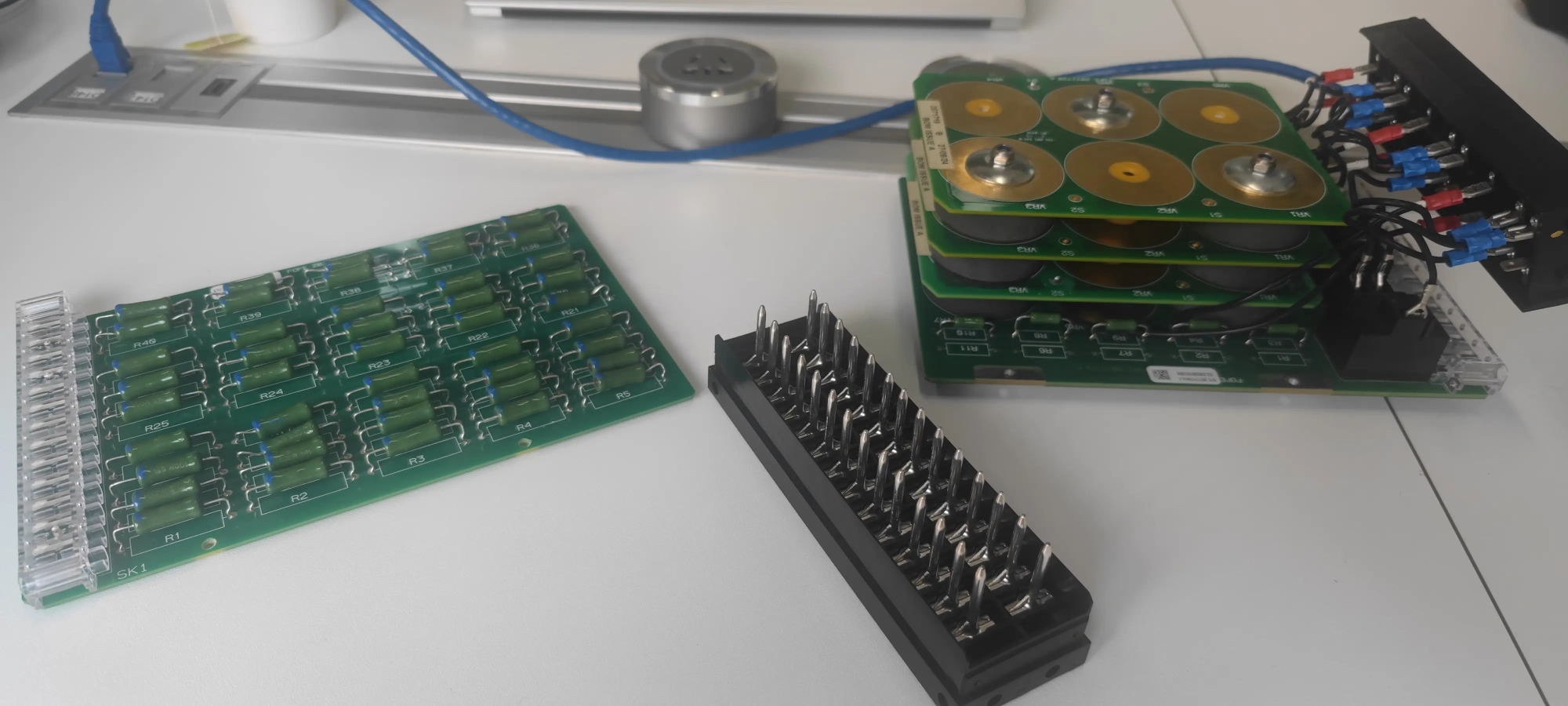

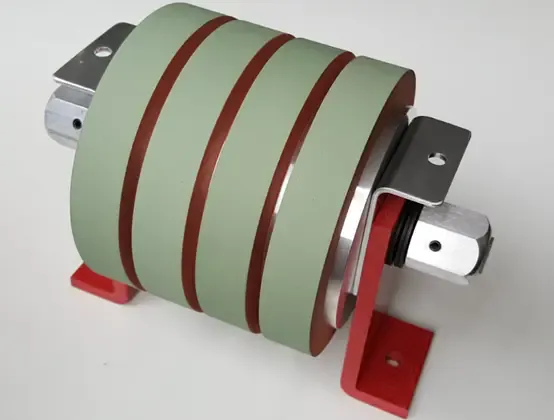

The optimal solution is a bulk ceramic, non-inductive power resistor with the following key attributes:

- Ultra-low inductance (≤10⁻⁷ H) to ensure fast, oscillation-free discharge

- High voltage gradient tolerance (up to 1.2 kV/cm in air)

- High energy absorption capacity (up to 250 J/cm³ for 1-second pulses)

- Robust ceramic construction resistant to thermal shock

- Stable resistance under high electric fields (low voltage coefficient)

For a 10 kV system, the resistor’s physical length becomes critical. With a maximum permissible voltage gradient of 1.2 kV per centimeter, a safe design requires a minimum active length of ~8.5 cm (10,000 V ÷ 1,200 V/cm ≈ 8.3 cm). In practice, engineers often select resistors 10–15 cm long to provide a safety margin against surface arcing, especially in humid or dusty industrial environments.

Typical Use Cases

Medium-Voltage Power Converters & Inverters In renewable energy systems (e.g., solar farms or wind turbines), 10 kV DC links use large capacitor banks for smoothing. Discharge resistors ensure safe maintenance after grid disconnection.

Industrial X-ray & Medical Imaging Equipment High-voltage generators in CT scanners or radiography units rely on fast, reliable capacitor discharge to prevent accidental exposure or equipment damage.

Pulsed Power & Test Laboratories In high-voltage testing facilities, capacitors are repeatedly charged and discharged. Resistors must handle frequent high-energy cycles without degradation.

Railway Traction Systems Regenerative braking systems in electric trains often involve 10 kV-class DC links. Discharge resistors provide fail-safe energy dissipation during emergencies.

Capacitor Bank Maintenance in Substations Utility-scale capacitor banks used for power factor correction must be discharged before servicing. Permanent or switchable discharge resistors are mandated by IEC 60831 and IEEE standards.

Cooling & Longevity Considerations

While a single discharge event may last milliseconds, repeated cycling demands attention to thermal recovery. In air-cooled setups, surface temperatures should not exceed 150–220°C, depending on resistance value. For systems requiring frequent discharges, forced-air or liquid cooling can multiply power-handling capacity by 10x to 40x—enabling compact designs even under heavy duty cycles.

Importantly, these resistors exhibit excellent long-term stability: under continuous load, resistance drift remains within ±20% over 2,000 hours, and storage under normal conditions causes less than ±3% variation over six months.

Design Best Practices

- Use E12 standard resistance values (e.g., 10 kΩ, 22 kΩ) for availability and compatibility

- Ensure adequate creepage and clearance between terminals and grounded parts

- Prefer silver-plated terminations if using liquid cooling to prevent corrosion

- Avoid varnish coatings in oil or water environments

- Model discharge time: t ≈ 3RC for 95% voltage decay (e.g., 10 kΩ + 10 µF → ~0.3 seconds)

Conclusion

In 10 kV capacitor systems, the discharge resistor is far more than a passive component—it’s a safety-critical safeguard. By selecting a purpose-built, non-inductive, high-energy resistor with proper voltage rating and thermal design, engineers ensure operational safety, regulatory compliance, and system longevity. Whether in energy, transportation, or industrial automation, the right discharge resistor doesn’t just manage energy—it protects lives.