In the development and validation of high-capacity battery systems, such as those used in electric vehicles (EVs) and energy storage solutions, accurate discharge testing is essential to evaluate performance, efficiency, and safety. One of the key components enabling this process is the water cooled resistor , which provides a stable, high-power load while managing thermal conditions effectively.

Application Overview

A leading battery manufacturer was conducting discharge tests on lithium-ion battery packs rated up to 800V and 1000A. The test required simulating real-world operating conditions, including continuous discharge under various load profiles. To ensure reliable and repeatable results, the company needed a resistive load capable of handling 10kW of power without significant temperature rise or resistance drift.

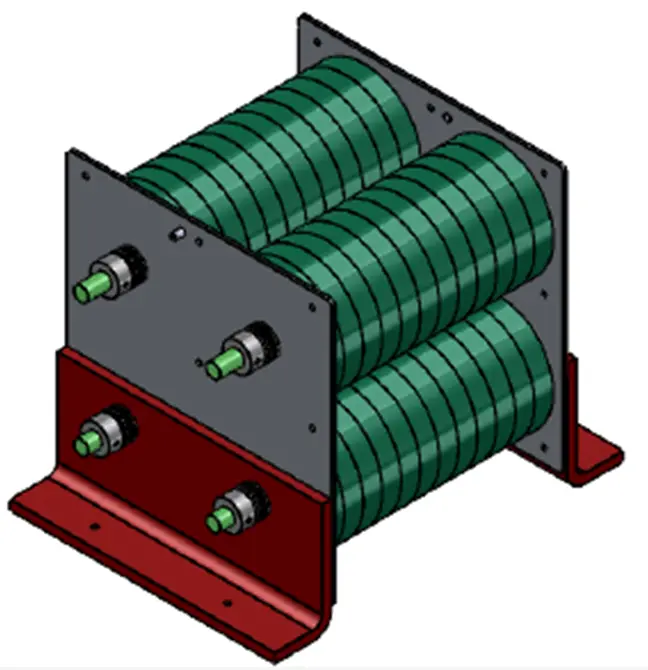

Water Cooled Resistors

Water Cooled Resistors

The solution involved deploying multiple water cooled resistors with precise resistance values:

- 10mΩ (range: 8.5–10mΩ)

- 25mΩ (range: 23–25mΩ)

- 50mΩ

- 100mΩ

- 200mΩ All with tolerance within 0 to -5%, and inductance below 100nH.

These low-inductance resistors were connected in parallel and series configurations to match different test scenarios, ensuring minimal electromagnetic interference (EMI) during operation.

Technical Advantages

Using water cooled resistors provided several critical advantages:

- Thermal Stability : Liquid cooling ensured that the resistance value remained constant even under high current, preventing thermal runaway and measurement inaccuracies.

- High Power Handling : Each resistor could dissipate up to 10kW continuously, making them ideal for long-duration battery discharge cycles.

- Low Inductance Design : With inductance under 100nH, these resistors minimized voltage spikes and noise during switching operations.

- Compact and Scalable : The modular design allowed easy integration into existing test benches and scalability for future expansion.

Test Results

By integrating water cooled resistors into their testing infrastructure, the battery manufacturer achieved:

- Improved repeatability and accuracy in discharge curve measurements

- Reduced downtime due to overheating

- Enhanced data integrity for battery management system (BMS) calibration

- Compliance with EMC/EMI standards during active testing

This case demonstrates how water cooled resistors are indispensable tools in modern battery R&D and quality assurance processes.

Case Study 2: Precision Load Simulation for EV Battery Testing Using Water Cooled Resistors

As electric vehicle (EV) technology advances, so does the need for rigorous and realistic testing of battery packs and modules. A major automotive supplier recently implemented a new battery test platform aimed at validating battery performance under dynamic load conditions. To simulate real-world usage accurately, the team incorporated water cooled resistors as primary load elements.

Project Requirements

The goal was to build a flexible and scalable test system capable of discharging batteries up to 10kW per module. Key requirements included:

- Resistance values ranging from 10mΩ to 200mΩ

- Tight tolerance of 0 to -5%

- Low inductance (<100nH) to minimize transient effects

- Stable performance under continuous high-current operation

Solution Implementation

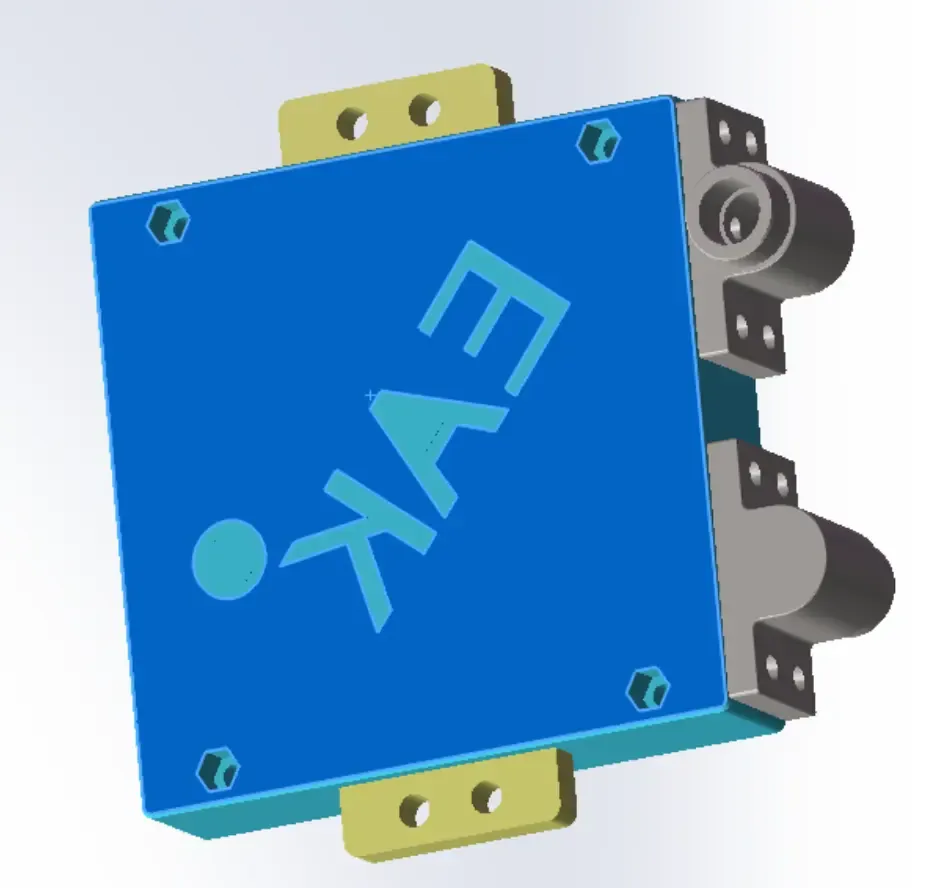

To meet these specifications, the engineering team selected custom-designed water cooled resistors engineered for high-precision applications. These resistors were built using non-inductive winding techniques and housed in corrosion-resistant enclosures compatible with standard glycol-based coolant systems.

Each resistor was tested individually to ensure compliance with the following parameters:

| Resistance | Tolerance | Max Power | Inductance |

|---|---|---|---|

| 10mΩ | 8.5–10mΩ | 10-45kW | <100nH |

| 25mΩ | 23–25mΩ | 10-45kW | <100nH |

| 50mΩ | ±5% | 10-45kW | <100nH |

| 100mΩ | ±5% | 10-45kW | <100nH |

| 200mΩ | ±5% | 10-45kW | <100nH |

The resistors were mounted in a modular rack system and integrated with programmable switches and monitoring instruments.

Performance Benefits

During testing, the use of water cooled resistors delivered notable benefits:

- Consistent Load Profiles : The resistors maintained stable resistance values throughout extended discharge cycles, improving the reliability of test data.

- Improved Safety : Effective heat dissipation reduced risks associated with overtemperature events.

- Reduced Maintenance : Compared to air-cooled alternatives, the liquid-cooled system experienced less component degradation and required fewer replacements.

- Enhanced EMI Compatibility : Low inductance minimized electrical noise, supporting cleaner signal measurements and better EMC compliance.

Conclusion

This project highlights the growing importance of water cooled resistors in EV battery testing environments. Their ability to provide precise, high-power loads with minimal thermal and electromagnetic interference makes them an ideal choice for modern battery evaluation systems.

Whether used in R&D labs or production line testing, water cooled resistors offer unmatched performance for engineers seeking accuracy, stability, and durability in battery testing applications.