The Problem: Destructive Arcing in Relay Switching

In industrial automation and power control systems, electromechanical relays and contactors routinely switch inductive loads—such as solenoids, motor windings, and transformer coils. When the contacts open, the abrupt interruption of current induces a high-voltage transient (back-EMF), often exceeding 1,000 volts. This leads to:

- Contact erosion and welding

- Premature relay failure

- Increased maintenance and downtime

A robust, passive solution is needed to clamp voltage spikes and absorb switching energy without interfering with normal circuit operation.

The Solution: Silicon Carbide (SiC) Varistors for Contact Protection

Silicon carbide (SiC) varistors—voltage-dependent nonlinear resistors—are engineered specifically for this challenge. Their key advantages include:

- Ultra-fast response (<1 µs) to voltage transients

- High energy absorption capacity (up to tens of joules per unit)

- Excellent thermal shock resistance due to sintered SiC-ceramic construction

- Compact form factor, ideal for integration near relay terminals

As noted in industrial technical references, SiC varistors are explicitly recommended for “protecting relay and contactor contacts by reducing the destructive energy of switching arcs.”

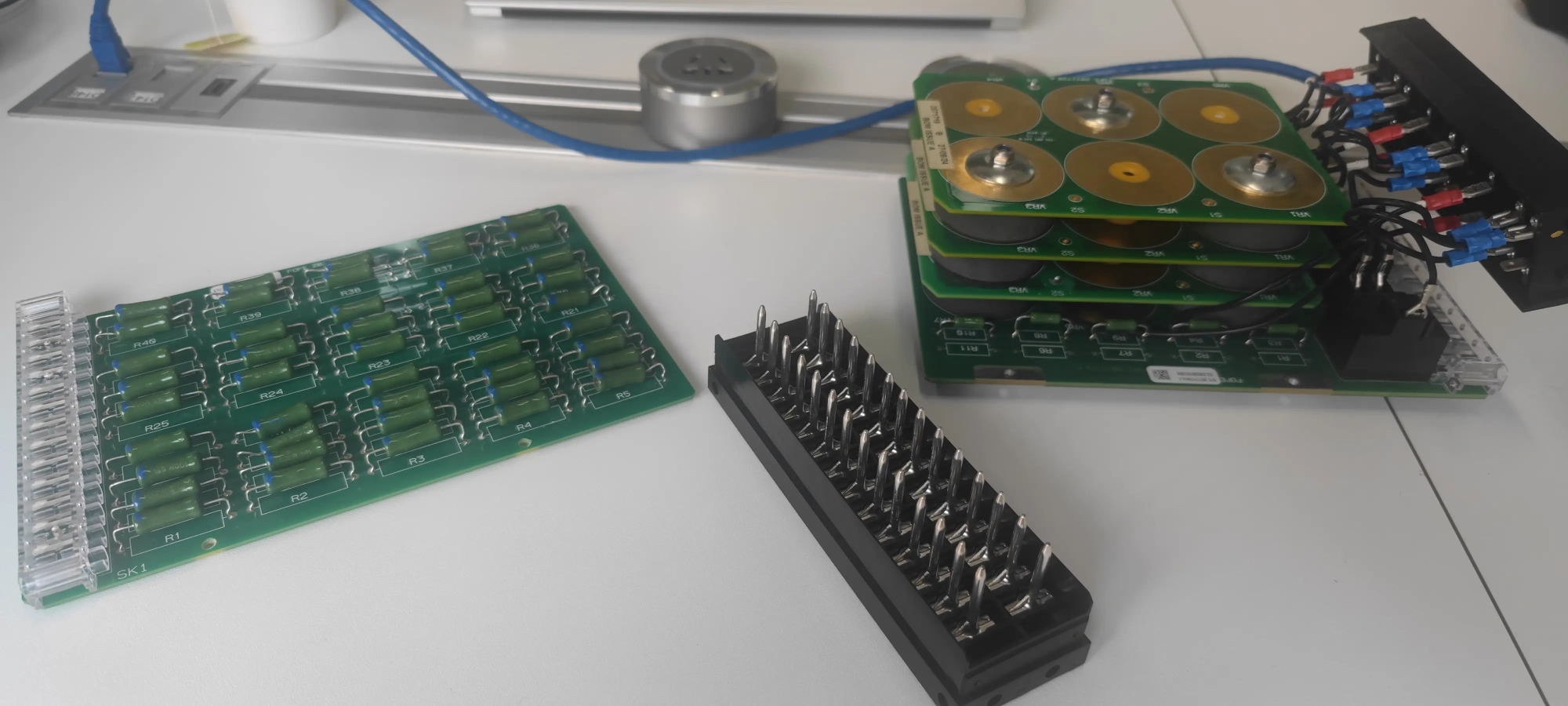

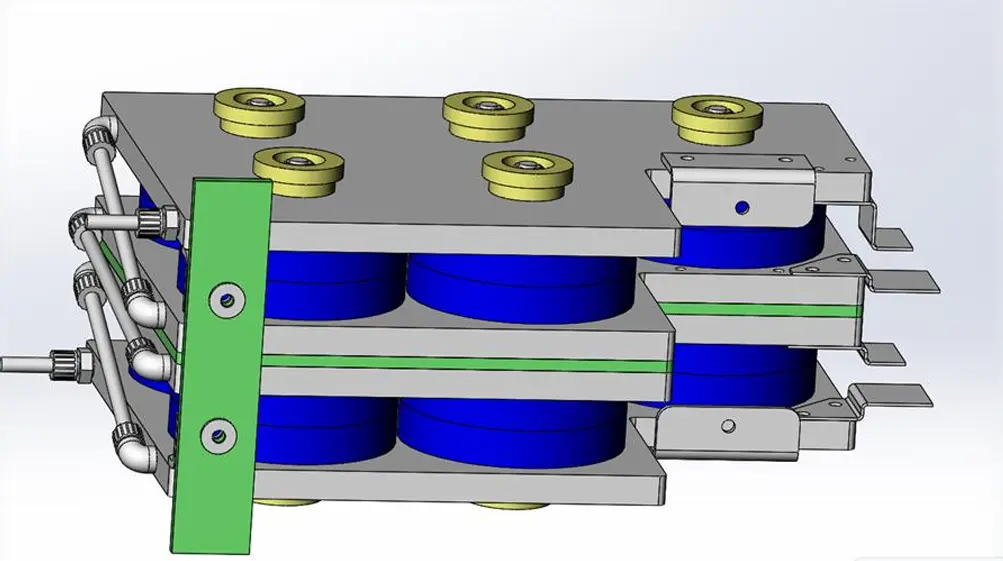

Optimized Design: Series-Parallel Arrays for Scalable Protection

For applications involving higher inductance, frequent switching, or elevated system voltages, a single varistor may be insufficient. Engineers commonly deploy custom series-parallel configurations to meet exact requirements:

- Series connection: Raises the overall clamping voltage threshold. Example: Two varistors in series double the effective voltage rating—ideal for 480V AC control circuits.

- Parallel connection: Increases total energy handling and current capacity. Example: Four identical units in parallel quadruple the absorbable energy, supporting heavy-duty or high-cycle applications.

Real-World Implementation: A 220V AC control relay switches a 500W hydraulic solenoid. Field measurements show transient voltages peaking at 800V during de-energization. Solution: Two matched SiC varistors connected in series are installed directly across the relay contacts. This setup ensures:

- Clamping voltage remains below 600V

- Energy per unit stays under safe limits

- Total operating temperature remains below 80°C (even at 40°C ambient) Result: Relay lifespan extended by 5×, with zero contact welding after 100,000+ operations.

Best Practices for Reliable Deployment

- Mount as close as possible to the relay contacts to minimize parasitic inductance.

- Verify energy per unit does not exceed the varistor’s rated absorption capacity.

- Account for ambient temperature and duty cycle—continuous or high-frequency switching requires thermal derating.

- Use matched units in parallel to ensure balanced current sharing and prevent overload on individual components.

Conclusion

Silicon carbide (SiC) varistors provide a proven, maintenance-free method to suppress switching transients and protect relay contacts in demanding industrial environments. By leveraging series-parallel arrays, system designers can precisely tailor protection to match voltage, energy, and reliability requirements—ensuring maximum uptime and component longevity.

Ideal for: industrial control panels, HVAC systems, machine tools, power distribution units, and any application involving inductive load switching.