The evolution of the electrical grid hinges on advanced power electronics, with the Solid-State Transformer (SST) standing out as a cornerstone technology for modern microgrids and smart charging infrastructure. Unlike its passive, bulky predecessor, the SST is a compact, bidirectional, and highly controllable device. However, its ability to manage rapid power flow and fault conditions requires equally advanced ancillary components. This case study explores how our 600KW rack-mounted liquid-cooled resistor served as a critical component for braking and DC-link stabilization in a high-power SST system.

The Client’s Challenge: Taming Regenerative Power in a Compact EV Charging Hub

A leading developer of fast-charging infrastructure for electric trucks and buses was deploying a new charging hub. Their system was built around a 1.2 MVA Solid-State Transformer, which provided galvanic isolation, voltage conversion, and bidirectional power flow capability.

The engineering team faced two critical challenges:

Regenerative Energy Surge: During a fault or a rapid shutdown of multiple charging stations, the energy stored in the system’s capacitance and any feedback from the load side would flow back into the SST’s DC-link. This caused a dangerous voltage spike (“DC-link overvoltage”) that threatened to destroy sensitive IGBTs and capacitor banks.

Space and Density Constraints: The charging cabinet had extremely limited space. Traditional air-cooled braking resistors were not feasible due to their massive size, the need for large clearance for airflow, and the unacceptable heat they would dump into the enclosed environment.

They needed a solution that could dissipate 600KW of peak power in a compact form factor, integrate seamlessly into the SST’s control system, and operate with utmost reliability.

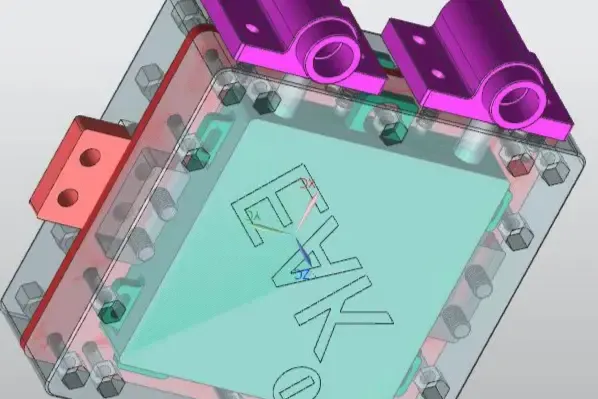

The Solution: Precision Engineering with the LQ-CoolR-600 Rack-Mounted Resistor

Our LQ-CoolR-600 600KW Rack-Mounted Liquid-Cooled Resistor was selected as the ideal braking/bleeder resistor solution. Its design directly addressed the client’s core challenges.

Key Product Specifications:

Peak Power: 600 kW (for up to 10 seconds)

Continuous Power: 15 kW (steady-state cooling capacity)

Cooling Method: Closed-loop liquid cooling (50/50 water-glycol mix)

Enclosure: Standard 19-inch, 4U rack-mount form factor

Connection: Low-inductance, heavy-duty busbar terminals for DC-link connection

Materials: Corrosion-resistant aluminum housing, robust internal resistor element

Control Interface: Dry contact signal for external contractor/IGBT drive

Technical Deep Dive: How the LQ-CoolR-600 Integrates with the SST

The integration of the LQ-CoolR-600 into the SST’s power management scheme is a masterpiece of system-level design.

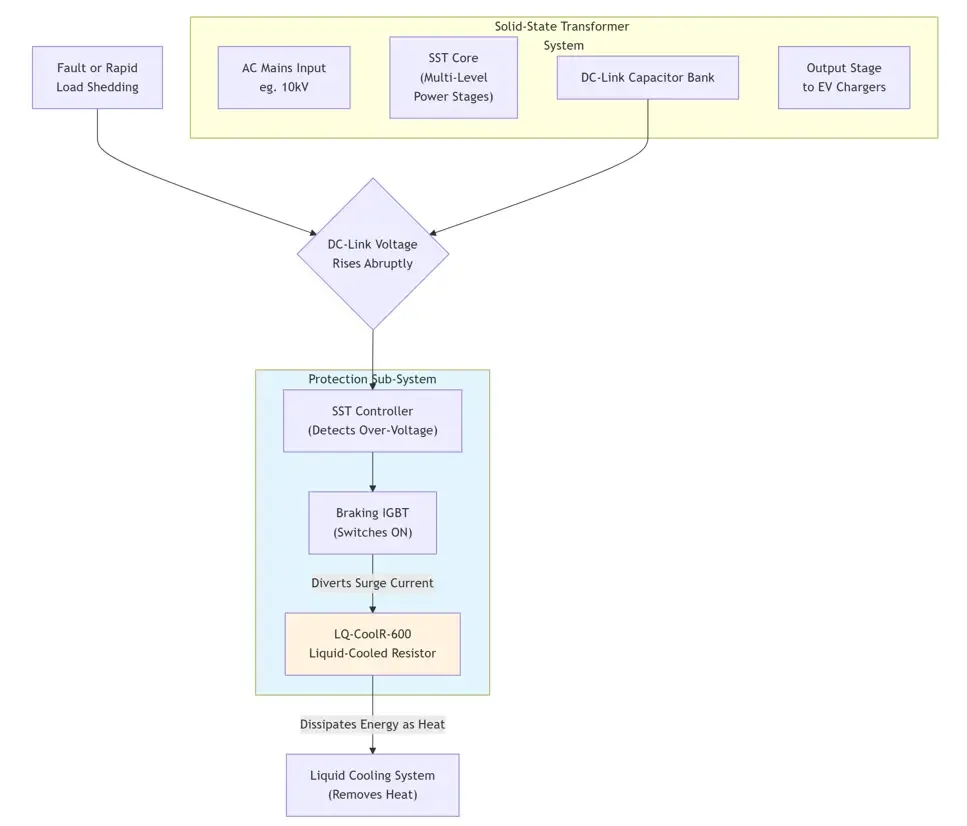

As illustrated above, the operational workflow is as follows:

Fault Detection: The SST’s master controller continuously monitors the DC-link voltage. During a charging session interruption, the voltage begins to rise rapidly.

Activation Signal: Once the voltage exceeds a pre-set threshold, the controller sends a gate signal to a high-power Braking IGBT (or a similar solid-state switch) connected in series with the LQ-CoolR-600.

Energy Diversion: The IGBT turns on, creating a controlled path for the excess energy to flow from the DC-link into the LQ-CoolR-600 resistor.

Power Dissipation: The resistor converts this electrical energy into heat with extreme efficiency and speed.

Heat Removal: The integrated liquid-cooling plate immediately absorbs the generated heat. The facility’s cooling loop continuously circulates coolant, transporting the heat away from the electronics cabinet and rejecting it to an external radiator or heat exchanger. This keeps the entire system at a safe operating temperature.

Measurable Benefits and Project Outcomes

By integrating the LQ-CoolR-600, the client achieved significant operational advantages:

Elimination of DC-Link Overvoltage Events: The system successfully clamped the DC-link voltage during multiple simulated and real-world fault conditions, protecting over $50,000 in sensitive power semiconductors.

90% Space Savings: The 4U rack-mounted design replaced a proposed air-cooled solution that would have required an entire separate enclosure, perfectly fitting within the existing SST power cabinet.

Enhanced System Reliability: The sealed, liquid-cooled design is immune to environmental contaminants like dust and moisture, which can degrade air-cooled resistors. It also operates silently.

Zero Exhaust Heat: By capturing and rejecting heat via liquid, the client avoided the need for complex and energy-intensive forced-air ventilation within the electronics enclosure, simplifying thermal management.

Conclusion: Why a Liquid-Cooled Resistor is Essential for Advanced Power Electronics

The success of this project underscores a critical trend in high-power electronics: as systems like Solid-State Transformers become more power-dense, their ancillary components must evolve accordingly.

The LQ-CoolR-600 600KW Rack-Mounted Liquid-Cooled Resistor was not merely a component but an enabling technology. It provided the robust, compact, and reliable power dissipation capability necessary for the SST to perform its advanced functions safely and reliably. For engineers designing the future of power conversion, rail transit, industrial drives, or renewable energy systems, liquid-cooled resistors are no longer a luxury—they are a necessity for managing extreme power in confined spaces.