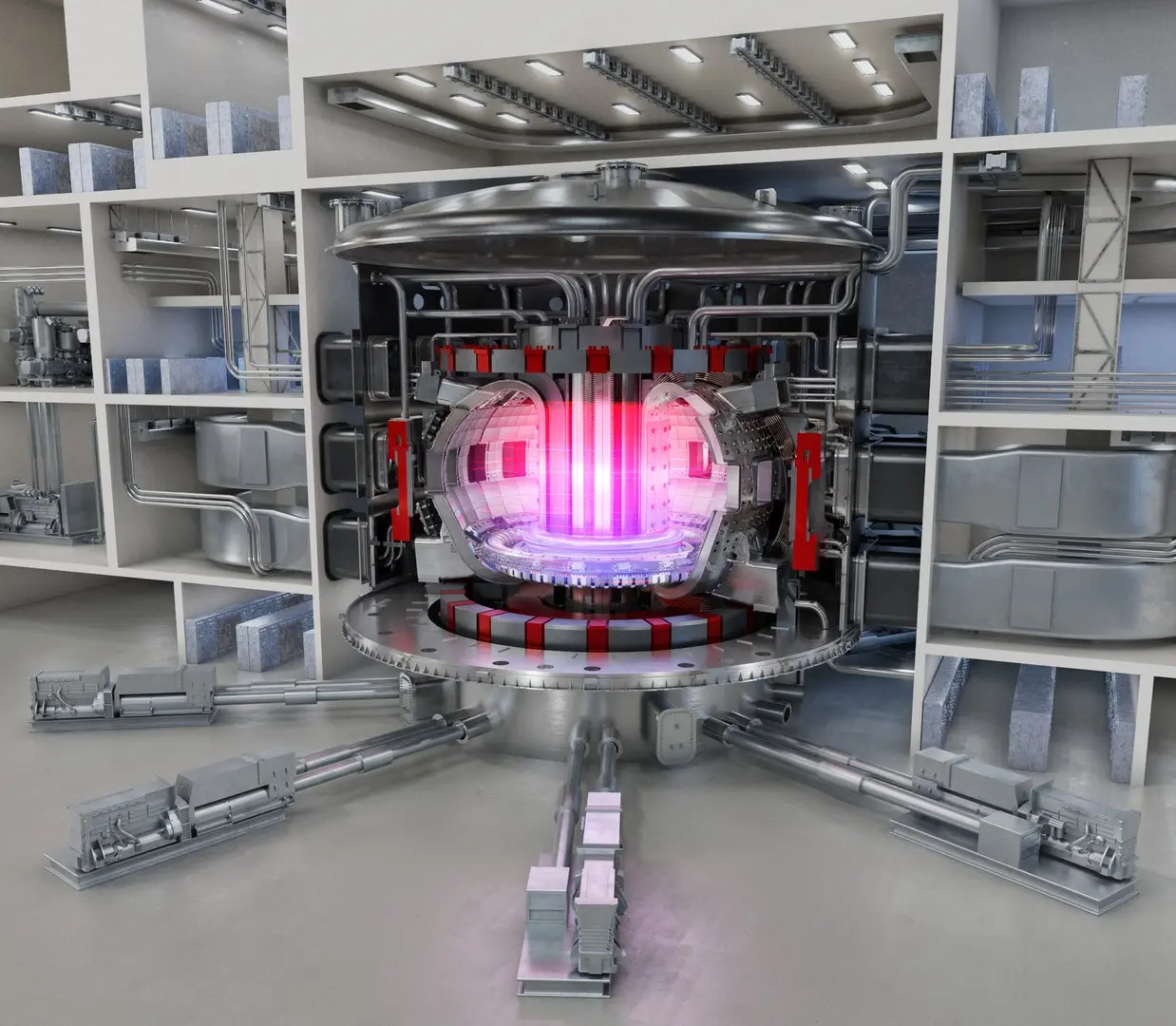

Nuclear fusion facilities, such as the {ITER} (International Thermonuclear Experimental Reactor) project, operate at the cutting edge of energy science, relying on massive superconducting magnet systems to confine plasma at millions of degrees Celsius. These magnets store astronomical amounts of electromagnetic energy—often tens of gigajoules. The safe and rapid discharge of this stored energy during an emergency shutdown or a Quench event (sudden loss of superconductivity) is arguably the most critical safety and engineering challenge. This function is performed by specialized, ultra-reliable components: Dump Resistors (or Discharge Resistors). Advanced SiC Electrically Conductive Ceramics are emerging as the only material capable of handling the extreme demands of this high-pulse, high-power application.

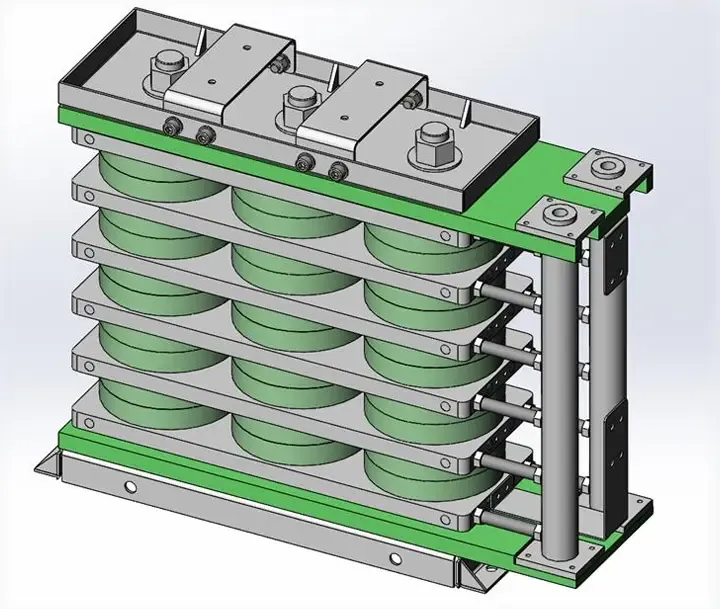

Discharge Resistors

Discharge Resistors

Section 1: The Challenge of Fusion Magnet Protection

Traditional metallic or wire-wound resistors struggle in this unique high-energy environment due to three primary constraints:

- Thermal Shock Catastrophe: A Quench event requires the Dump Resistor to absorb the stored energy in seconds. This instantaneous surge creates immense thermal stress, often causing traditional resistive materials to crack, deform, or even fail catastrophically.

- Volumetric Constraints: Fusion facilities require compact, high-density energy absorption. Traditional resistor banks are large and complex, adding significant spatial overhead.

- Reliability in Extreme Fields: Components must function flawlessly while being exposed to powerful electromagnetic fields and, in some areas, significant neutron radiation flux.

Section 2: SiC Conductive Ceramics: Engineered for GJ-Scale Energy Absorption

Our ultra-low resistivity SiC conductive ceramics, featuring a resistivity of 10^{-7} Ω m, offer the ideal solution for robust Fusion Reactor Dump Resistors by leveraging a unique combination of integrated material properties:

A. Exceptional Thermal Shock Resistance

- SiC Advantage: Silicon Carbide exhibits superior thermal shock stability compared to conventional metals or oxides. This is paramount for Dump Resistors, as the SiC body can convert the rapid, high-current pulse into heat and absorb the resultant extreme temperature gradient without structural failure.

- The Benefit: Guarantees the reliability and structural integrity of the energy dissipation system during emergency magnet discharges, protecting multi-billion dollar superconducting assets.

B. High Power Density and Compact Design

- SiC Advantage: SiC has excellent thermal conductivity and can withstand temperatures up to 1400^\circ C. This means the material can safely handle and dissipate far more power per unit volume than traditional resistive alloys.

- The Benefit: Enables the design of more compact, higher power-density Dump Resistor banks, reducing the footprint and complexity of the fusion reactor’s auxiliary systems.

C. Stable, Low-Loss Discharge

- SiC Advantage: The 10^{-7} \Omega \cdot m$ ultra-low resistivity ensures that the required resistance value is highly stable and uniform. Furthermore, the material’s structural purity is beneficial in high magnetic fields.

- The Benefit: A stable, predictable resistance is vital for controlling the discharge time constant (tau = L/R) of the superconducting magnets. Precise control over the energy discharge rate is essential for maintaining magnet health and preventing irreversible damage.

Section 3: Application Case Scenario – Superconducting Quench Protection

In a typical Quench scenario within a \text{Tokamak} facility, the rapid decay of the magnetic field induces a powerful current and voltage spike.

The SiC Conductive Ceramic Dump Resistor is configured to absorb this discharge pulse:

- Instantaneous Loading: The high pulse rating of the SiC ceramic allows it to absorb the initial high-voltage spike without breakdown.

- Efficient Heat Management: As the GJ of energy is converted into heat, the SiC resistor’s high thermal conductivity ensures the heat is spread quickly and effectively throughout the component, preventing localized hot spots that lead to failure in conventional materials.

- Long-Term Reliability: The material’s inherent strength ensures the resistor component remains physically stable and electrically reliable over multiple operational cycles throughout the fusion reactor’s lifespan.

The successful operation of future Nuclear Fusion power plants hinges on the reliability of components like Dump Resistors and Discharge Resistors. \text{SiC} Electrically Conductive Ceramics represent a fundamental material advancement, offering the necessary thermal resilience, electrical precision, and mechanical robustness to protect superconducting magnets under the most extreme pulsed power conditions. We are ready to partner with global fusion research and engineering programs to customize and scale this technology for demanding high-energy applications.