Safety is paramount in any high-voltage system, and an 800V HVDC architecture is no exception. Capacitors, inherent to many HVDC designs, can store substantial amounts of electrical energy even after the power supply is disconnected. This stored energy poses a significant shock hazard. This is where bleeder resistors come into play.

Safety is paramount in any high-voltage system, and an 800V HVDC architecture is no exception. Capacitors, inherent to many HVDC designs, can store substantial amounts of electrical energy even after the power supply is disconnected. This stored energy poses a significant shock hazard. This is where bleeder resistors come into play.

Their primary function is to safely and efficiently discharge stored energy from capacitors and other high-voltage components when the system is powered down. This rapid discharge prevents dangerous residual voltages and ensures personnel safety during maintenance or system shutdown.

When selecting bleeder resistors for an 800V HVDC system, several factors are crucial:

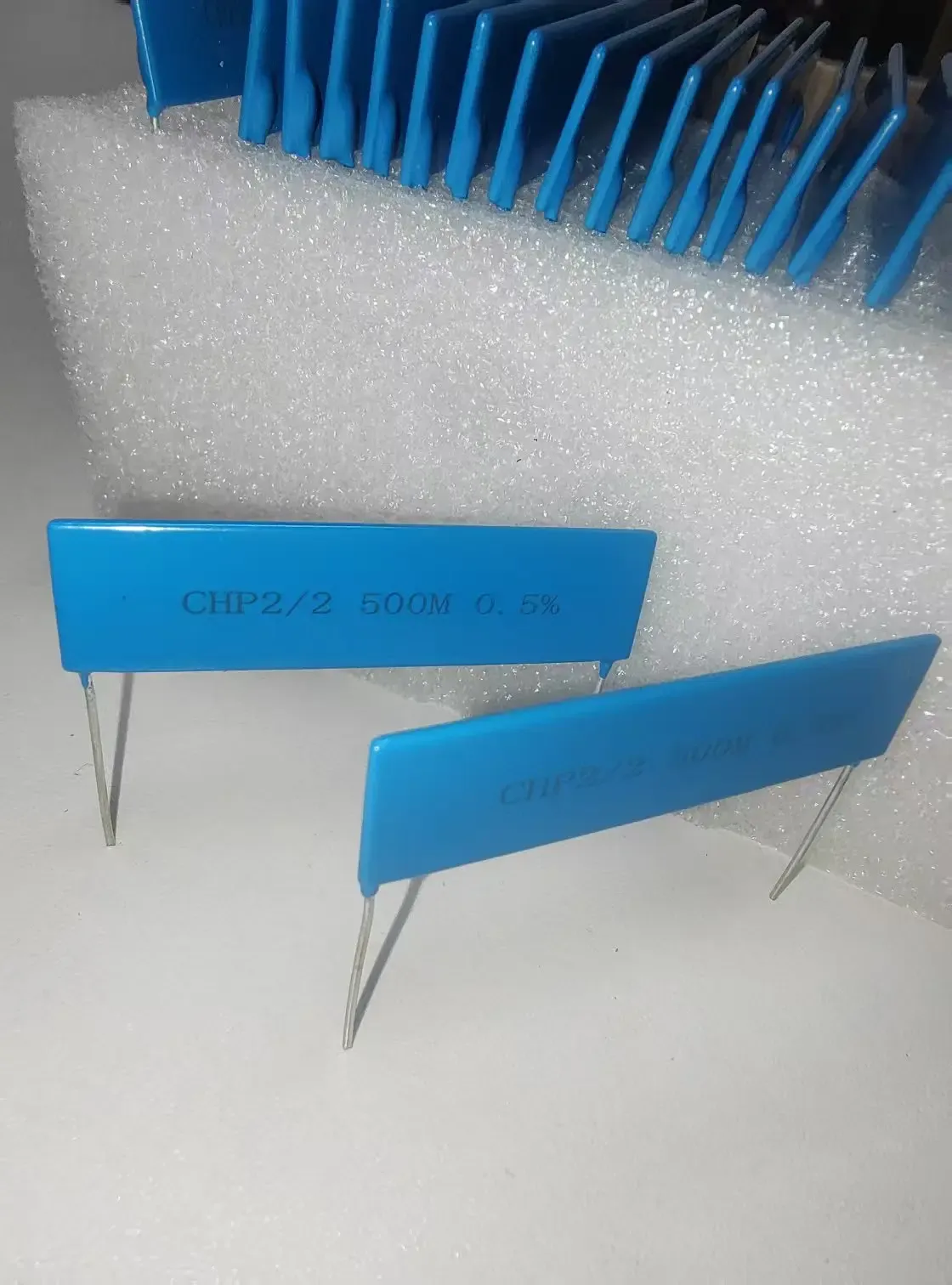

- High Voltage Rating: The resistor must be able to withstand the full 800V DC voltage, often with a significant safety margin (e.g., rated for 1000V or more). For very high voltages, it’s common to use a series combination of several resistors to distribute the voltage stress.

- Power Dissipation Capability: Bleeder resistors must be capable of dissipating the stored energy, which can translate to high instantaneous power. The larger the capacitance and voltage, the greater the energy stored and the higher the required power rating for the bleeder resistor to achieve a quick discharge.

- Pulse Withstand Capability: During discharge, bleeder resistors experience a sudden surge of current. Therefore, they need excellent pulse withstand characteristics to prevent damage and ensure long-term reliability.

- Reliability: Given their safety-critical function, bleeder resistors must exhibit high reliability and stability over their operational lifetime.

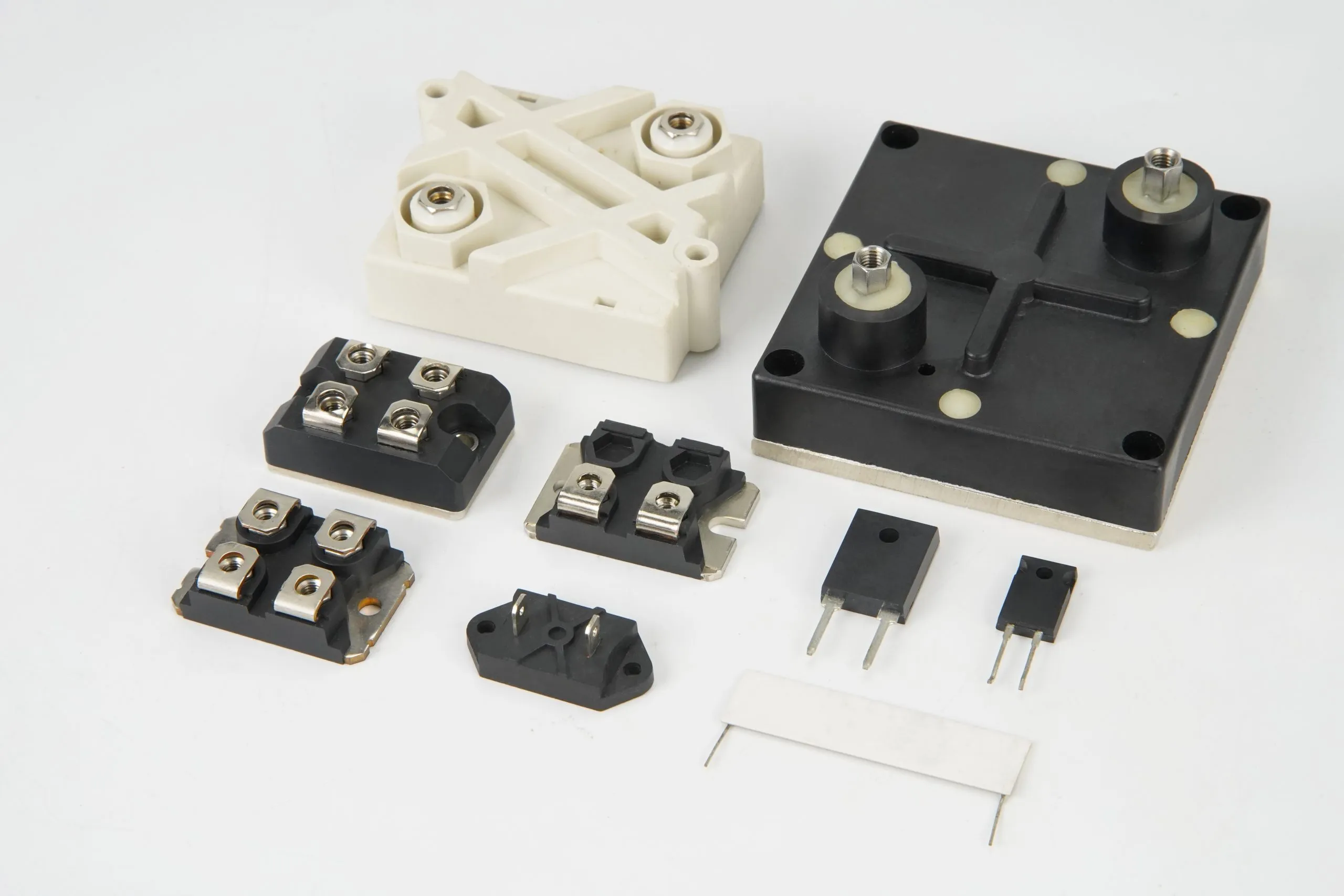

Common types of resistors used as bleeder resistors include wire-wound resistors, known for their robust power handling, and specialized high-voltage thick film resistors that offer compact size and good pulse performance.

Thick Film Power Resistors: Robustness for High Power Applications

Thick film power resistors are a cornerstone in 800V HVDC distribution due to their robust construction and excellent power dissipation capabilities. These resistors are manufactured by screen-printing a thick resistive paste onto a ceramic substrate, followed by firing at high temperatures. This process results in a durable resistor that can handle significant power levels in a relatively compact footprint.

Their advantages in an 800V HVDC system include:

- High Power Density: Thick film technology allows for substantial power dissipation in a smaller physical size compared to some other resistor types, which is beneficial in space-constrained HVDC designs.

- Good High Voltage Performance: While individual thick film resistors might have specific voltage limitations, they can be designed or combined in series to safely handle 800V DC. Specialized high-voltage thick film resistors are explicitly engineered for such applications.

- Pulse Withstand Capability: Many thick film power resistors are designed to withstand high current pulses, making them suitable for applications like pre-charging circuits or snubber networks in HVDC systems.

- Reliability and Stability: The robust construction contributes to good long-term stability and reliability under demanding operating conditions.

Beyond bleeder applications, thick film power resistors are often found in voltage dividers for monitoring, snubber circuits for protecting switching devices, and in some current sensing applications where high power dissipation is required.

Current Limiting Resistors: Protecting Components and Controlling Inrush

Current limiting resistors are fundamental to protecting sensitive components and managing current flow in an 800V HVDC system. Their primary role is to restrict the magnitude of current to a safe level, preventing damage to other components and controlling potentially harmful inrush currents.

Key applications and considerations for current limiting resistors in 800V HVDC include:

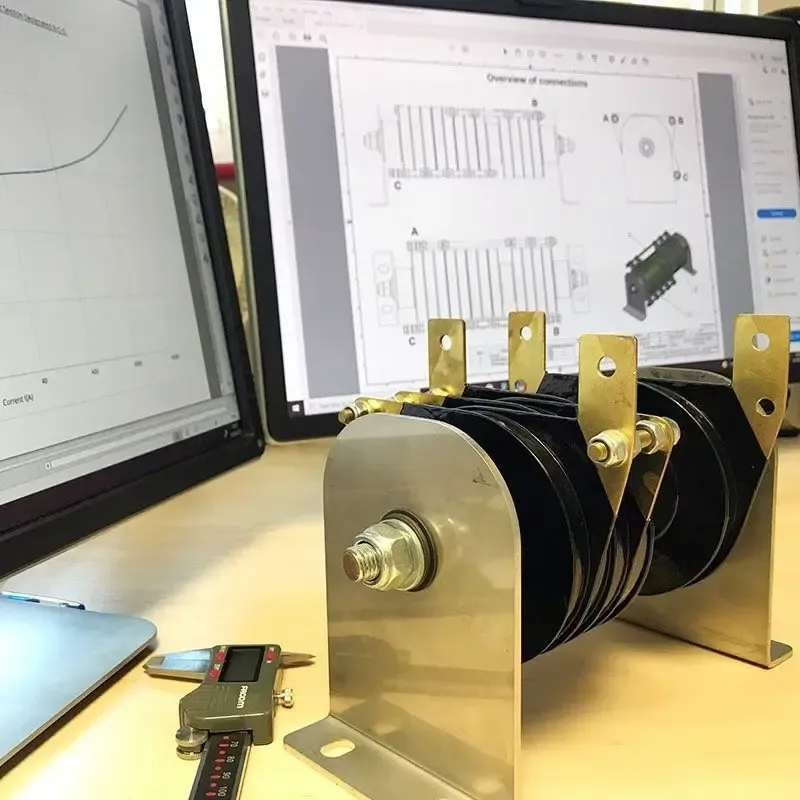

- Pre-charge Circuits: When connecting an HVDC bus to large capacitors or other inductive loads, an enormous inrush current can occur, potentially damaging power electronic switches (like IGBTs or MOSFETs) or blowing fuses. A current limiting resistor, often a power resistor, is used in a pre-charge circuit to slowly charge the capacitors or inductors, limiting the initial current surge. Once the voltage reaches a safe level, a contactor typically bypasses the pre-charge resistor.

- Gate Drive Circuits: In power converter stages, current limiting resistors might be used in the gate drive circuits of switching devices to control the charging and discharging of the gate capacitance, thus influencing switching speeds and preventing excessive gate currents.

- Fault Protection: In certain fault conditions, a current limiting resistor can temporarily restrict fault currents, allowing protective devices (like fuses or circuit breakers) to react before widespread damage occurs.

- LED Drivers and Indicator Circuits: Even in an 800V system, there might be lower-voltage auxiliary circuits that require current limiting for LEDs or other indicators.

When selecting current limiting resistors, you’ll need to consider:

- Resistance Value: Determined by the desired current limit and the voltage drop across the resistor.

- Power Dissipation: The resistor must be able to handle the continuous or intermittent power dissipated across it.

- Voltage Rating: Crucial to ensure the resistor doesn’t break down under the system’s operating voltage.

- Temperature Coefficient of Resistance (TCR): For precise current limiting, a low TCR is desirable to maintain consistent resistance across temperature variations.

Conclusion

Choosing the right resistors for an 800V HVDC distribution architecture is a critical design decision that directly impacts the system’s safety, efficiency, and longevity. Bleeder resistors are non-negotiable for personnel safety, ensuring rapid discharge of stored energy. Thick film power resistors provide robust power handling in compact forms, suitable for various demanding applications. And current limiting resistors are essential for protecting sensitive components and managing critical current flows, particularly during system startup. By carefully selecting these components based on their voltage, power, and specific application requirements, engineers can build reliable and safe high-voltage DC systems.