In modern power systems, closing resistors (Ceramic Carbon Resistors) are widely used key components, especially in high power circuit breakers, where their role is particularly important. The following is an application case based on a power rating of 550KV, demonstrating their practical value in enhancing the safety and reliability of electrical equipment.

Background

With the acceleration of industrialization, the power and operational environment requirements for various electrical equipment are increasingly demanding. In power systems, 550KV devices typically involve the control of large motors, transformers, and other critical equipment. To avoid damage to the equipment caused by high surge currents during sudden closure, closing resistors are introduced into the design of circuit breakers. The primary function of the closing resistor is to limit the current at the moment of closing, thereby protecting electrical equipment and extending its service life.

System Design

In this application case, a 550KVmotor is controlled by a circuit breaker equipped with a closing resistor. The rated voltage of this circuit breaker is 400V, with a rated current close to 800A. By integrating the closing resistor, the motor does not receive the full rated current immediately upon circuit closure; instead, the current gradually rises through the discharging of the closing resistor. The specific design is as follows:

1. Selection of Closing Resistor**: Based on the rated power and rated current of the motor, an appropriate closing resistor is selected to ensure that the current does not exceed the rated value during closure. For the 550KV motor, a closing resistor with a value of approximately 0.5Ω is chosen.

2. Control Circuit Design: The closing resistor is connected to the circuit breaker, and relays in the control circuit will be activated at the moment of closing. Initially, the connection is made through the resistor, and after a few seconds, the switch disconnects the resistor, allowing the motor to smoothly transition to normal operating conditions.

Effect Analysis

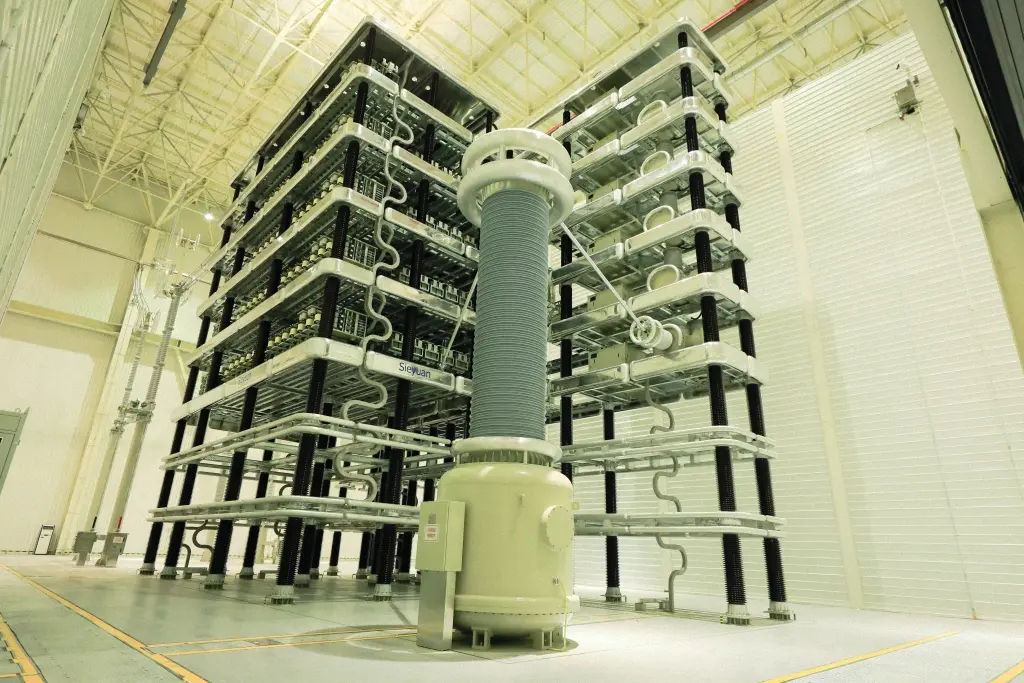

Closing Resistors (Ceramic Carbon Resistors)

Closing Resistors (Ceramic Carbon Resistors)

After implementing this solution, the operation of the generator set showed significant improvement. Actual tests indicated that the surge current brought about by the closing resistor was reduced by over 30%, effectively avoiding potential damage to the motor and other distribution equipment caused by current surges. With the use of closing resistors, maintenance costs for the equipment were lowered, and the failure rate significantly reduced.

Moreover, the ceramic carbon material of the closing resistor exhibits good thermal stability and high voltage resistance, maintaining good performance even after multiple closure operations, ensuring the stable operation of the electrical system. Additionally, because the closing resistor can absorb instantaneous energy pulses, it further protects the power supply system and loads, enhancing the safety of electrical equipment.

Conclusion

By introducing closing resistors in a 550KV circuit breaker, the reliability and safety of the entire power system have been significantly improved. For example, it enhances the equipment’s adaptability to transient currents during startup and operation, reducing the risk of equipment failure and damage. This case fully illustrates the importance of closing resistors in high-power electrical applications and provides strong assurance for the stable operation of industrial power systems.