Data Center Server

Data Center Server

An immersion liquid-cooled dummy load cabinet is a device that combines liquid cooling technology with load simulation technology, mainly used for high-power testing and thermal management in fields such as data centers and power systems. When designing such equipment, it is necessary to comprehensively consider factors such as the power requirements of the data center, heat dissipation capacity, coolant selection, safety, and reliability. Below are the key design considerations along with some specific quantitative case studies.

Design Considerations

1. Power Range Matching The power demand of data centers is typically measured on a per-cabinet basis, with single-cabinet power generally ranging from 5kW to 30kW. In certain high-performance computing (HPC) or AI training scenarios, it can reach 50kW or even higher. The design of the dummy load cabinet needs to cover the target power range and have a certain amount of redundancy.

2. Selection of Liquid Cooling System Coolant Selection: Common coolants include deionized water, mineral oil, and fluorinated liquids. Fluorinated liquids have good insulation and thermal conductivity but are more expensive; mineral oil is less costly but may have volatility issues. - Flow Rate and Head of Circulation Pump: The required flow rate and head must be calculated based on the load power and the heat capacity of the coolant to ensure timely heat removal.

3. Thermal Management System Heat Exchanger Design: The dummy load cabinet must be equipped with an efficient heat exchanger to transfer heat from the coolant to the external environment or a secondary cooling system. Temperature Control Precision: Typically, temperature fluctuations should not exceed ±2°C to avoid overheating or uneven cooling.

4. Electrical Design Load Element Selection: The core of the dummy load cabinet is the resistor element, which requires materials with high-temperature resistance and high power density (such as nichrome alloy, silicon carbide, etc.). Circuit Protection: Overload protection, short-circuit protection, and insulation monitoring functions need to be designed to ensure safe operation of the equipment.

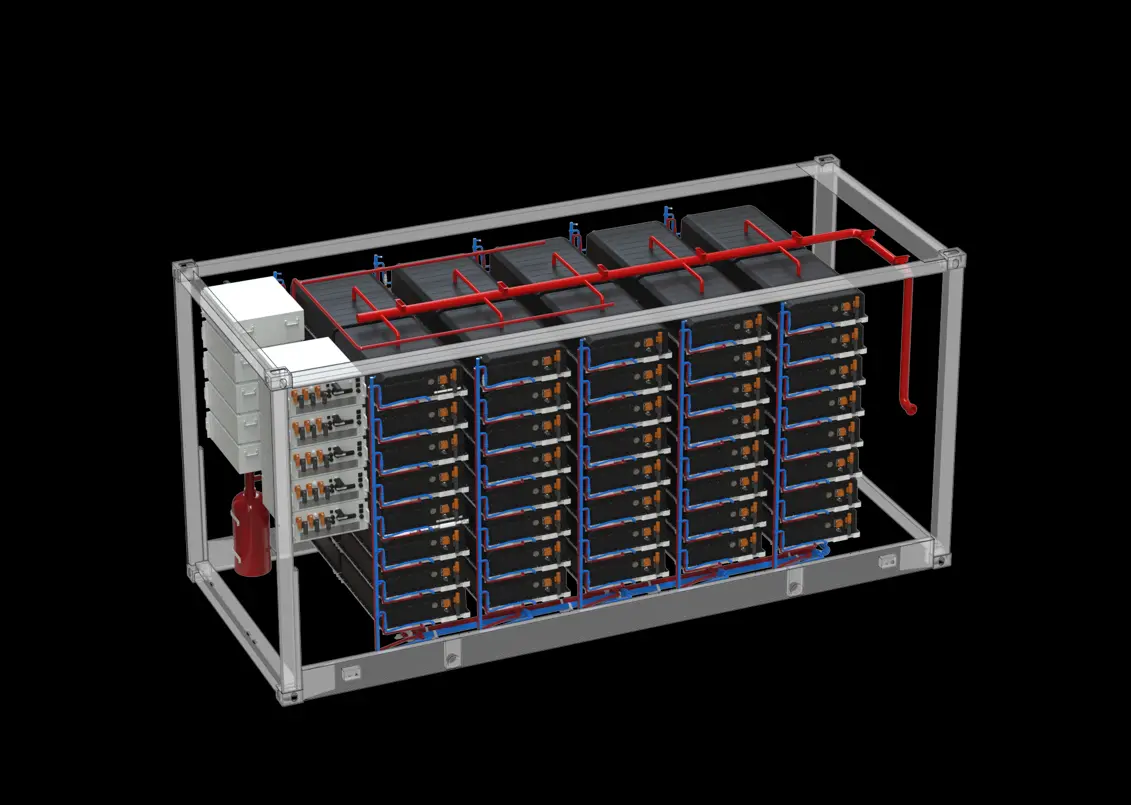

5. Structural Design Cabinet Sealing: Immersion liquid cooling requires the cabinet to have good sealing performance to prevent coolant leakage. Maintenance Convenience: The design should consider ease of maintenance and inspection, such as modular design and quick component replacement.

6. Intelligent Monitoring Integrated Sensors: Real-time monitoring of coolant temperature, flow, pressure, as well as load current, voltage, and power parameters. Data Visualization: Display operational status through touch screens or remote monitoring systems, supporting fault alarms and data analysis.

Specific Quantitative Case Studies

Case 1: Medium-Sized Data Center (Single-Cabinet Power 10kW) Application Scenario**: Ordinary enterprise-level data centers, used for server testing or acceptance. Design Parameters**: Power Range: 10kW Coolant: Deionized Water Flow Requirement: Approximately 30L/min (assuming a temperature rise of 10°C) Heat Exchanger Efficiency: 85% Cabinet Dimensions: Standard 19-inch rack (600mm×800mm×2000mm) Load Elements: Nichrome alloy resistors, grouped modular design. Features: Lower cost, suitable for medium and small power testing needs. Strong scalability, power upgrades possible by adding load modules.

Case 2: Large Data Center (Single-Cabinet Power 30kW) Application Scenario: Cloud computing data centers or high-performance computing clusters. Design Parameters: Power Range: 30kW Coolant: Fluorinated liquid (e.g., Novec 7100) Flow Requirement: Approximately 90L/min (assuming a temperature rise of 10°C) Heat Exchanger Efficiency: 90% Cabinet Dimensions: Customized design (800mm×1200mm×2200mm) Load Elements: Silicon carbide resistors, high power density design. Features: Efficient heat dissipation, suitable for high power density scenarios. Good insulating properties of the coolant, high safety. Supports multi-cabinet parallel operation to meet larger-scale testing needs.

Case 3: Super Large Data Center (Single-Cabinet Power 50kW) Application Scenario: AI training centers or supercomputing centers. Design Parameters: Power Range: 50kW Coolant: Mineral oil (cost optimization solution) Flow Requirement: Approximately 150L/min (assuming a temperature rise of 10°C) Heat Exchanger Efficiency: 95% Cabinet Dimensions: Customized design (1000mm×1500mm×2500mm) Load Elements: Composite material resistors, ultra-high power density. Features: Ultimate power testing, meeting future high power density demands. Better cost control, suitable for large-scale deployment. Requires dedicated coolant circulation and filtration systems.

Summary

The design of an immersion liquid-cooled dummy load cabinet needs to be customized according to the actual power requirements of the data center. Here are some key quantitative references: Power Range: 5kW50kW (can be extended as needed). Coolant Flow Rate: Approximately 30L/min per 10kW of power (assuming a temperature rise of 10°C). Heat Exchanger Efficiency: 85%95%, depending on the application scenario. Cabinet Dimensions: Standard or customized design, balancing heat dissipation efficiency and space utilization.

In practical applications, it is also necessary to combine the customer’s budget, site conditions, and technical requirements for detailed design and optimization. If you need further discussion on a specific case, please provide more detailed requirement information.