Water-cooled resistors are commonly used for testing lithium batteries due to their ability to handle high power loads efficiently and safely . Here’s a breakdown of why they’re particularly well-suited for this application:

🔋 1. High Power Dissipation

Lithium battery testing — especially during discharge or performance evaluation — involves drawing large amounts of current , which generates significant heat.

- Water-cooled resistors can dissipate hundreds of kilowatts of power.

- They prevent overheating by continuously removing heat via the circulating coolant (usually water or a water-glycol mixture).

Why it matters: Without effective cooling, standard resistors would overheat, fail, or pose a fire hazard.

🌡️ 2. Stable Performance Under Load

Battery testing often requires precise control over load conditions (e.g., constant current, constant power discharge profiles).

- Water-cooled resistors maintain stable resistance values even under high thermal stress.

- This ensures accurate and repeatable test results .

Why it matters: Consistent performance is critical for evaluating battery capacity, efficiency, lifespan, and safety.

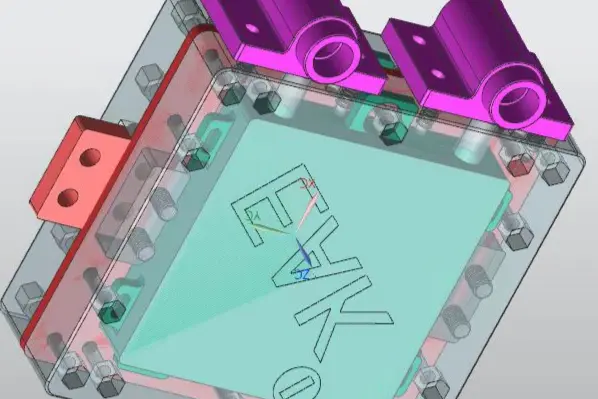

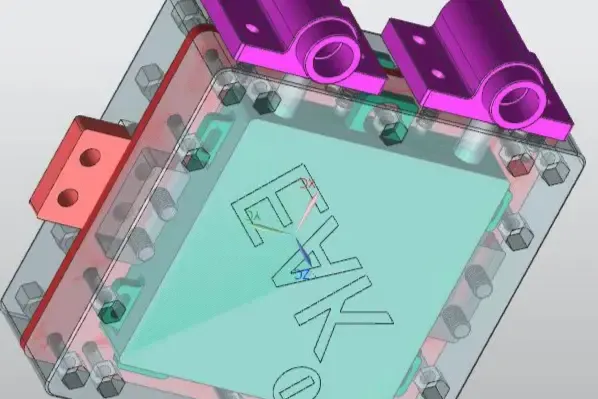

⚙️ 3. Compact Design for High-Density Applications

Despite handling large power levels, water-cooled resistors can be designed to be relatively compact compared to air-cooled alternatives.

- This is especially important in automated battery testing systems where space is limited.

Why it matters: Smaller footprint allows for modular and scalable test setups.

💧 4. Efficient Thermal Management

Water has a much higher specific heat capacity than air, making it far more efficient at removing heat.

- Water cooling allows continuous operation under high-power conditions without degradation.

- It also reduces ambient temperature rise in the test environment.

Why it matters: Efficient thermal management extends resistor life and improves system reliability.

🔬 5. Suitability for Regenerative and Dynamic Testing

In advanced battery testing (like regenerative braking simulations or pulse discharging), dynamic load changes occur rapidly.

- Water-cooled resistors respond quickly to these changes.

- They support dynamic load profiling and realistic simulation of real-world usage .

Why it matters: Realistic testing helps optimize battery performance for applications like EVs and energy storage systems.

✅ Summary: Why Use Water-Cooled Resistors for Lithium Battery Testing?

| Benefit | Description |

|---|---|

| High Power Handling | Dissipates kW–kW+ levels safely |

| Stable Operation | Maintains accuracy under high thermal stress |

| Compact Footprint | Saves space in automated test rigs |

| Reliable Cooling | Enables continuous, long-duration tests |

| Precise Control | Supports complex discharge profiles |

📌 Common Applications:

- Electric vehicle (EV) battery testing

- Grid-scale energy storage testing

- R&D labs for new battery chemistries

- Quality assurance and compliance testing

water-cooled resistors

water-cooled resistors

Let me know if you’d like a comparison between water-cooled vs. air-cooled resistors or examples of specific resistor models used in battery testing!