In the world of power electronics testing, reliability, efficiency, and thermal management are non-negotiable. As industries push toward higher power densities—especially in electric vehicles (EVs), renewable energy, and industrial automation—the demand for robust, scalable, and stable electronic loads has never been greater. One critical component enabling this evolution is the 25kW liquid-cooled resistor, a game-changer in high-power electronic load applications.

The Challenge of High-Power Load Testing

Traditional air-cooled electronic loads work well for low to medium power applications (typically under 5kW). However, when testing systems that generate 10kW, 20kW, or more—such as EV motor controllers, battery banks, or grid-tied inverters—heat buildup becomes a major bottleneck. Air cooling simply can’t dissipate heat fast enough, leading to thermal throttling, inconsistent performance, and even equipment failure.

This is where liquid-cooled resistors step in—and a 25kW liquid-cooled resistor offers the perfect balance of power capacity, compact design, and long-term reliability.

What Makes a 25kW Liquid-Cooled Resistor Ideal for Electronic Loads?

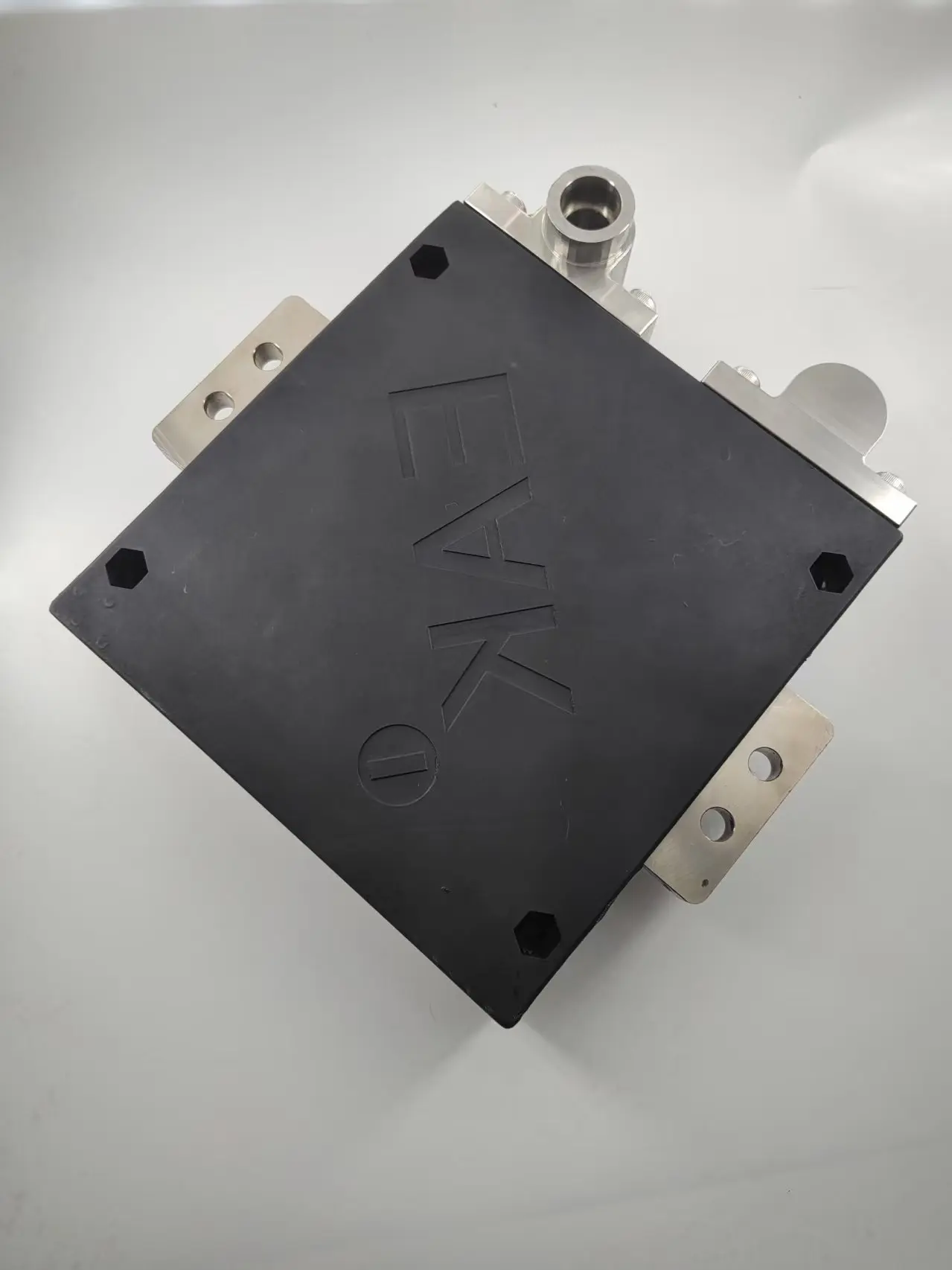

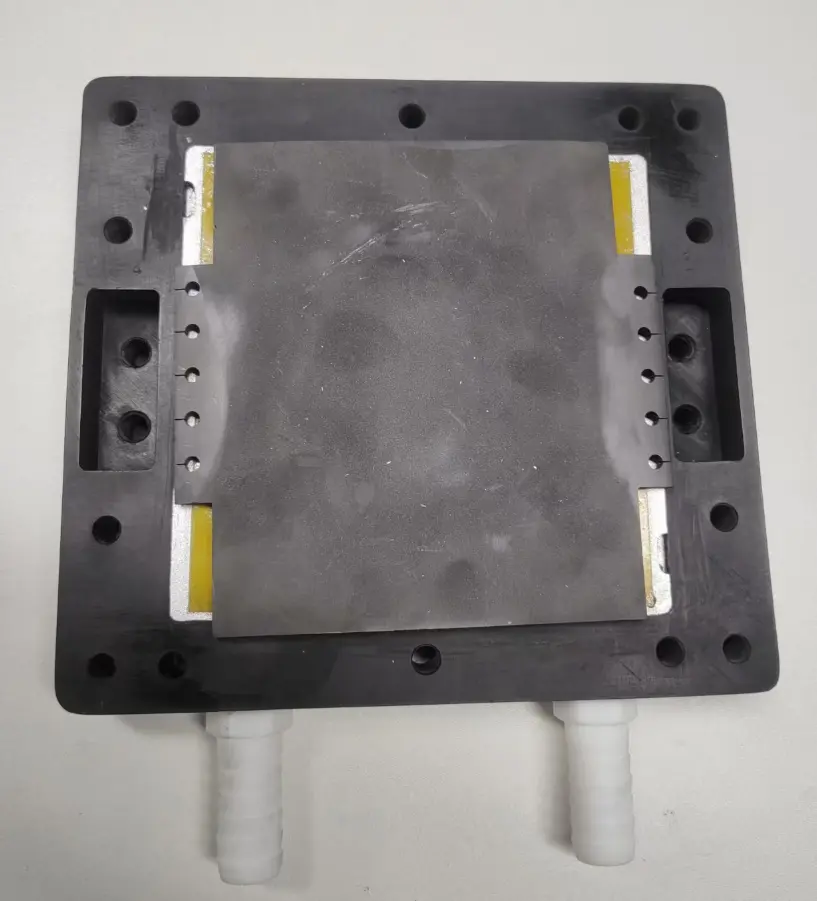

A 25kW liquid-cooled resistor is engineered to absorb and dissipate large amounts of electrical energy efficiently by circulating coolant (usually water or a water-glycol mix) through internal channels. This design allows it to maintain stable resistance values under continuous high-load conditions, making it ideal for:

- Battery discharge testing – Simulating real-world load profiles for EV and energy storage systems.

- Regenerative load simulation – Absorbing energy from motor drives during dynamic braking tests.

- Power supply burn-in and stress testing – Ensuring reliability under maximum load for extended durations.

- Renewable energy system validation – Testing solar inverters and wind turbine converters at full power.

Unlike air-cooled units, a 25kW liquid-cooled resistor operates with minimal temperature rise, ensuring consistent performance and extending the lifespan of both the resistor and the overall test system.

Superior Thermal Management = Higher Test Accuracy

Thermal stability is crucial in precision testing. Resistance values can drift with temperature, leading to inaccurate current or power readings. A liquid-cooled resistor maintains a near-constant temperature, even under full 25kW load, ensuring high measurement accuracy and repeatability.

Additionally, liquid cooling allows for:

- Smaller footprint – No need for large heatsinks or high-speed fans.

- Lower noise levels – Essential for lab environments.

- Higher power density – More performance in less space.

Integration with Programmable Electronic Loads

Modern 25kW liquid-cooled resistors are designed to integrate seamlessly with programmable electronic load systems. They can be used as the core power absorption module in constant resistance (CR), constant current (CC), or dynamic load modes. With fast response times and high stability, they support complex test profiles, including:

- Step-load changes (e.g., 0 to 25kW in milliseconds)

- Pulsed load simulations

- Long-duration endurance tests

Many systems also support remote monitoring and control via Ethernet, CANbus, or analog I/O, enabling full automation in production and R&D environments.

Real-World Applications

- EV Testing: Used in dynamometer setups to absorb regenerative energy from electric motors.

- Battery Manufacturing: Validates capacity and cycle life of large-format lithium-ion batteries.

- Aerospace & Defense: Powers rigorous testing of onboard power systems under extreme conditions.

- Data Center UPS: Tests backup power systems at full load without overheating.

Sustainability and Energy Recovery (Bonus Advantage)

While most liquid-cooled resistors dissipate energy as heat, some advanced setups pair them with heat recovery systems—capturing thermal energy for facility heating or industrial processes. Though not energy recovery like regenerative loads, this approach improves overall energy efficiency in test labs.

Conclusion

When it comes to high-power electronic load applications, a 25kW liquid-cooled resistor is no longer a luxury—it’s a necessity. It delivers unmatched thermal performance, reliability, and precision, enabling engineers to push the limits of modern power systems safely and efficiently.

Whether you’re validating the next-generation EV battery or stress-testing a solar inverter, integrating a 25kW liquid-cooled resistor into your test setup ensures accurate results, reduced downtime, and future-ready scalability.