As AI and high-performance computing (HPC) reshape data center infrastructure, the shift toward 48V DC power distribution has become a game-changer—offering up to 20% higher efficiency compared to legacy 12V systems by drastically reducing I²R losses. However, this efficiency gain comes with a new challenge: how to safely and accurately test ultra-high-density power systems that can exceed 50kW per rack—and even reach 500kW+ during commissioning.

Enter the rack-mounted liquid-cooled resistor: the critical, yet often overlooked, component enabling reliable validation of next-generation 48V DC architectures.

The Testing Challenge of 48V High-Power Systems

When deploying or upgrading a data center, engineers must simulate full-load conditions to verify the integrity of power distribution units (PDUs), busbars, UPS systems, and cooling infrastructure. Traditional air-cooled load banks simply can’t keep up. At multi-hundred-kilowatt levels, they generate excessive heat, require massive ventilation, and disrupt ambient temperatures—defeating the very efficiency goals of 48V systems.

Liquid-cooled resistors solve this by integrating directly into the data center’s existing liquid cooling loop (e.g., via a CDU—Cooling Distribution Unit). Instead of dumping waste heat into the room, they transfer it efficiently into the coolant—often water or a water-glycol mix—allowing seamless thermal management without overloading CRAC systems.

Why Rack-Mounted Liquid-Cooled Resistors Are Essential

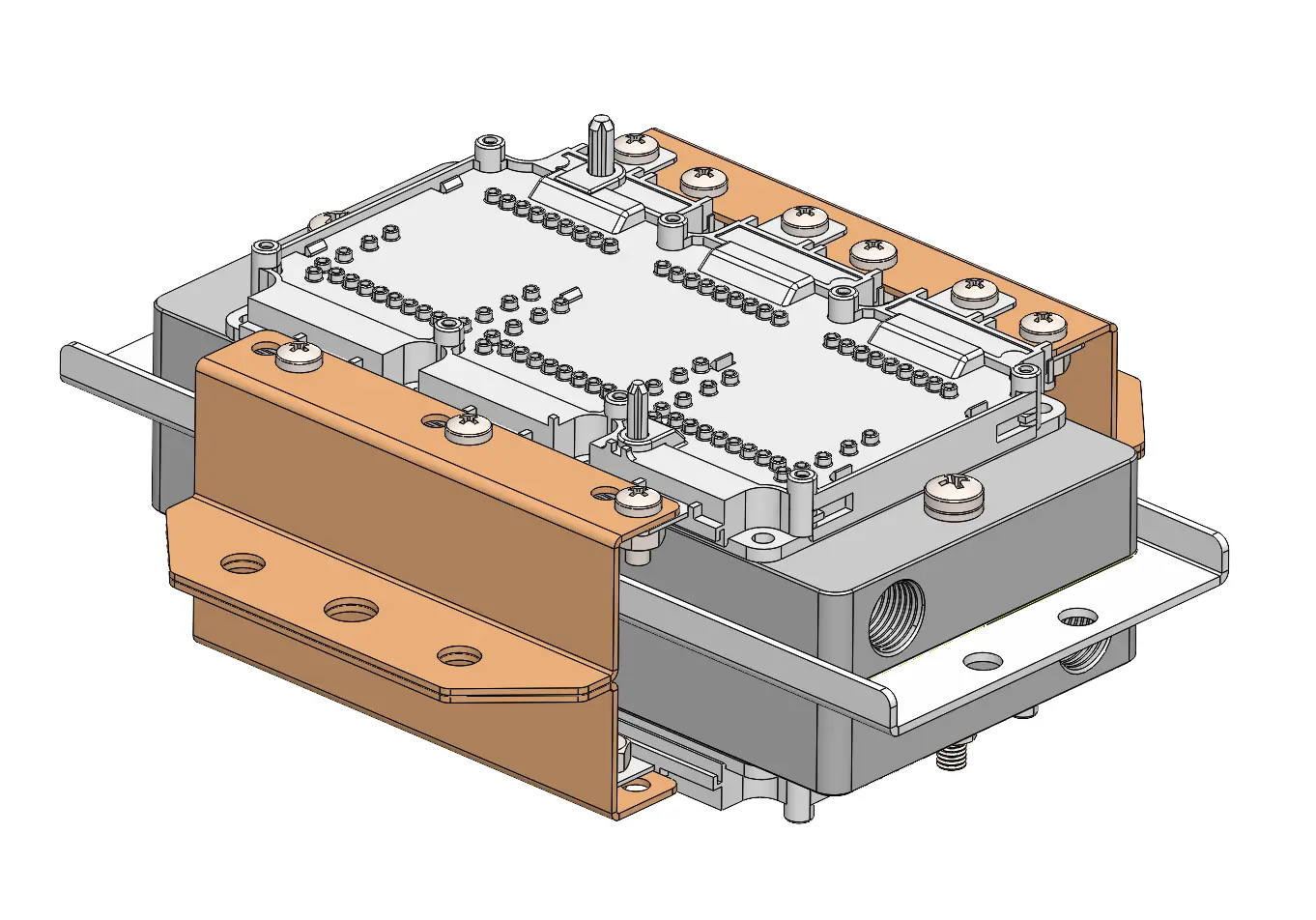

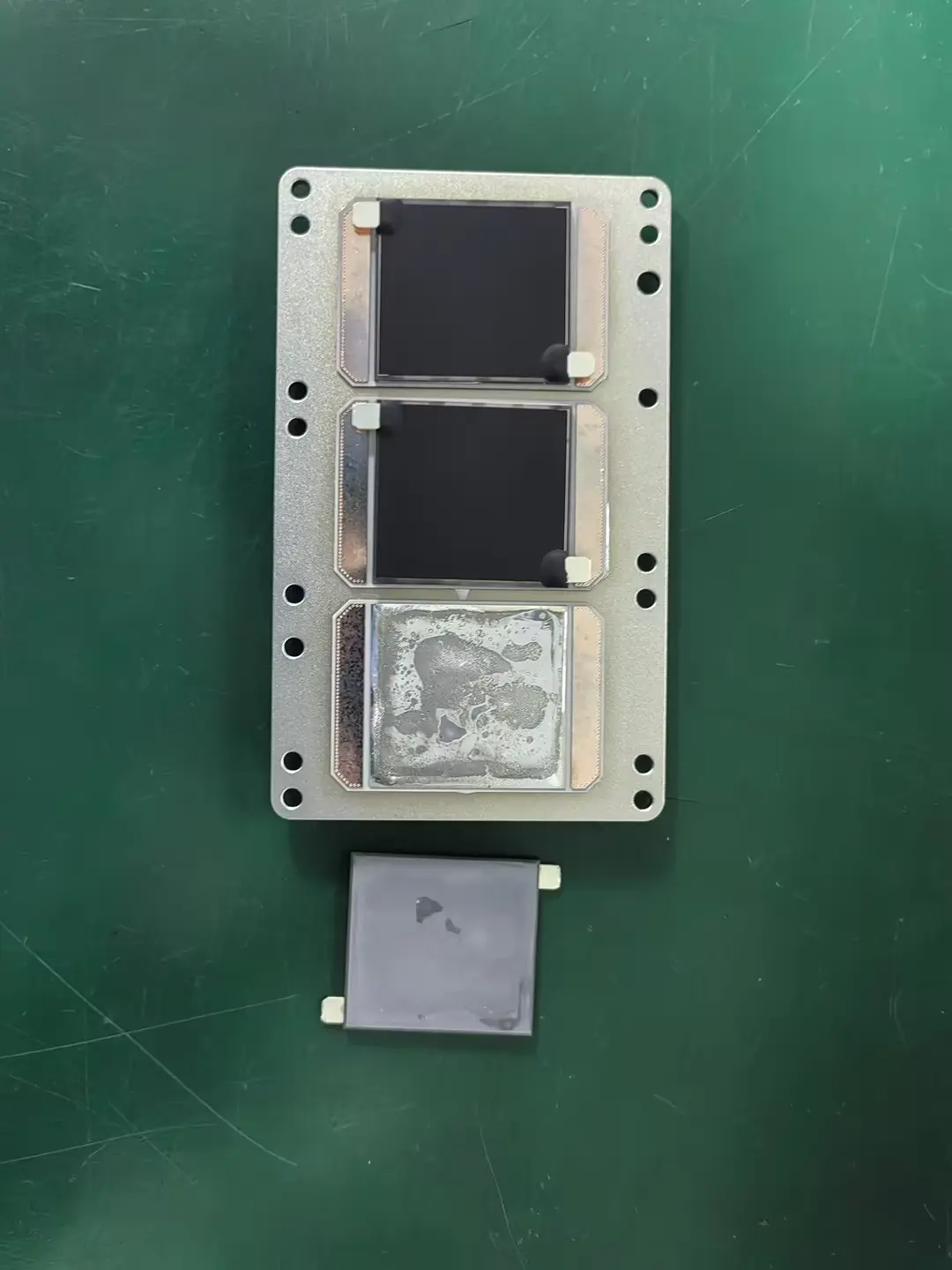

- Unmatched Power Density Modern liquid-cooled resistor modules deliver 10–15 kW per liter, enabling compact, rack-mounted designs that occupy just 10% of the footprint of equivalent air-cooled units. This is vital in space-constrained AI/HPC facilities where every U of rack space counts.

- Seamless Integration with 48V Infrastructure Designed specifically for 48V DC distribution, these resistors act as precision dummy loads that mimic real server behavior—testing voltage stability, current balancing, and fault response under dynamic conditions. Leading solutions (e.g., Thermon’s Poseidon series or Aggreko’s liquid-cooled load banks) support scalable configurations up to 600kW, with modular units that can be paralleled for hyperscale deployments.

- Zero Additional Thermal Load Heat generated during testing is captured at the source and routed through the same liquid loop used for GPU or CPU cooling. This “thermal neutrality” aligns perfectly with sustainable data center goals, reducing overall energy use by 20–35% during commissioning and supporting PUE optimization.

- Silent, Reliable, and Safe With no fans or moving parts, liquid-cooled resistors operate at **<35 dB**, ideal for noise-sensitive environments. They also feature **IP56+ protection**, high-voltage isolation (>1kV), and real-time monitoring of temperature, pressure, and flow—ensuring safe operation in 48V medium-voltage DC environments.

Beyond Commissioning: Future-Proofing Your Infrastructure

While primarily used during system validation and commissioning, rack-mounted liquid-cooled resistors are also valuable for:

- Redundancy and failover testing

- Dynamic load profiling (e.g., simulating AI training power spikes)

- Battery and energy storage system validation

As data centers move toward fully liquid-cooled architectures, these resistors will increasingly share mechanical and thermal interfaces with IT hardware—enabling plug-and-play deployment and unified thermal management.

Conclusion

The rise of 48V DC power distribution isn’t just about efficiency—it’s about enabling the extreme power densities demanded by AI. But without the right test infrastructure, even the most advanced power system remains unproven. Rack-mounted liquid-cooled resistors bridge this gap, offering a compact, efficient, and integrated solution for validating the backbone of tomorrow’s data centers.

For engineers designing or upgrading AI-ready facilities, investing in liquid-cooled load technology isn’t optional—it’s essential for reliability, scalability, and sustainability.

Discover how liquid-cooled resistors can streamline your 48V DC commissioning process—contact us today for a custom solution.