Boost Semiconductor Process Stability with Advanced Carbon Ceramic Resistors

The demand for ever-smaller, more powerful semiconductors pushes the boundaries of manufacturing technology. At the heart of this challenge lies the need for extreme precision and stability in high-temperature environments, particularly within diffusion furnaces and Chemical Vapor Deposition (CVD) equipment. In these critical applications, traditional heating elements and gas distribution components often struggle to maintain consistent performance, leading to process variations and reduced yields. This is where the innovative technology of carbon ceramic resistors emerges as a game-changer.

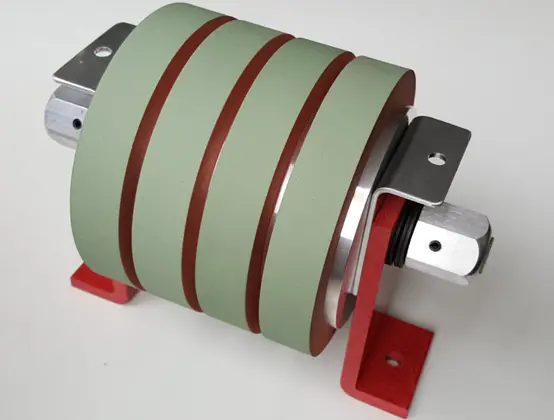

Carbon ceramic resistors are engineered to thrive in the harshest conditions. Unlike conventional materials, their unique composition offers exceptional thermal stability, chemical inertness, and mechanical strength at the elevated temperatures—often exceeding 1000°C—found in semiconductor processing. This inherent robustness makes them ideal for use as heating elements, ensuring uniform temperature distribution across the wafer. Consistent heating is paramount for achieving precise doping profiles in diffusion and uniform film growth in CVD, directly translating to enhanced device performance and reliability.

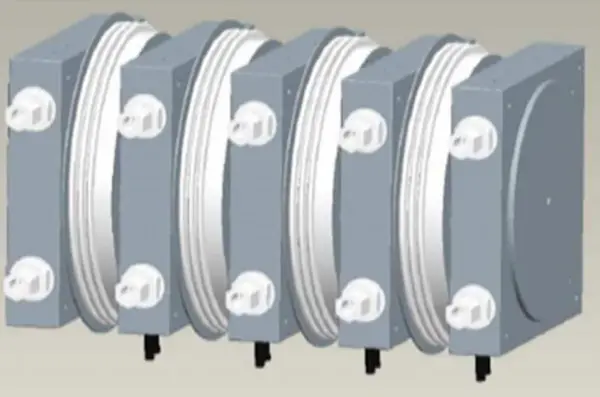

Furthermore, the superior properties of carbon ceramic resistors extend to gas distribution components. In CVD processes, accurate and stable gas flow is crucial for depositing thin films with desired characteristics. Carbon ceramic components resist degradation from reactive process gases and thermal cycling, preventing contamination and maintaining precise gas delivery. This translates to fewer defects, higher yields, and a significant improvement in overall process repeatability.

Investing in high-quality carbon ceramic resistors for your diffusion and CVD equipment is a strategic move towards achieving unparalleled process stability. By minimizing temperature fluctuations and ensuring consistent gas distribution, these advanced resistors empower semiconductor manufacturers to optimize their processes, reduce costly rework, and ultimately produce higher quality, more reliable devices. Future-proof your semiconductor manufacturing with the inherent advantages of carbon ceramic technology.