In the world of high-power electronics, managing energy dissipation is a constant engineering challenge. As systems grow more compact and powerful—especially in data centers, electric vehicle testing, and industrial motor drives—traditional air-cooled components often fall short. Enter the liquid-cooled resistor, a game-changing solution that, when integrated with chopper circuits, delivers unmatched thermal performance, reliability, and control. In this blog, we explore how liquid-cooled resistors are transforming chopper-based applications and why they’re essential for next-generation power systems.

What Is a Chopper Circuit?

A chopper is a high-frequency DC-DC switching circuit that modulates input voltage to regulate output power. By rapidly turning a semiconductor switch (like an IGBT or MOSFET) on and off, it controls the average voltage or current delivered to a load. While choppers are commonly used in voltage conversion (e.g., buck or boost converters), they also play a critical role in energy dissipation systems—particularly when paired with high-power resistors.

Why Pair Choppers with Resistors?

In applications like regenerative braking or dynamic electronic loading, excess electrical energy must be safely and efficiently converted into heat. A fixed-value power resistor is ideal for this task—but only if it can handle continuous high wattage without overheating. This is where the synergy begins: the chopper acts as a precision-controlled switch, connecting the resistor to the DC bus only when needed. By adjusting the duty cycle, engineers can precisely regulate how much energy is dumped into the resistor—without changing its physical value.

However, at power levels exceeding several kilowatts, air cooling becomes impractical. That’s where liquid-cooled resistors step in.

The Role of Liquid-Cooled Resistors in Chopper Systems

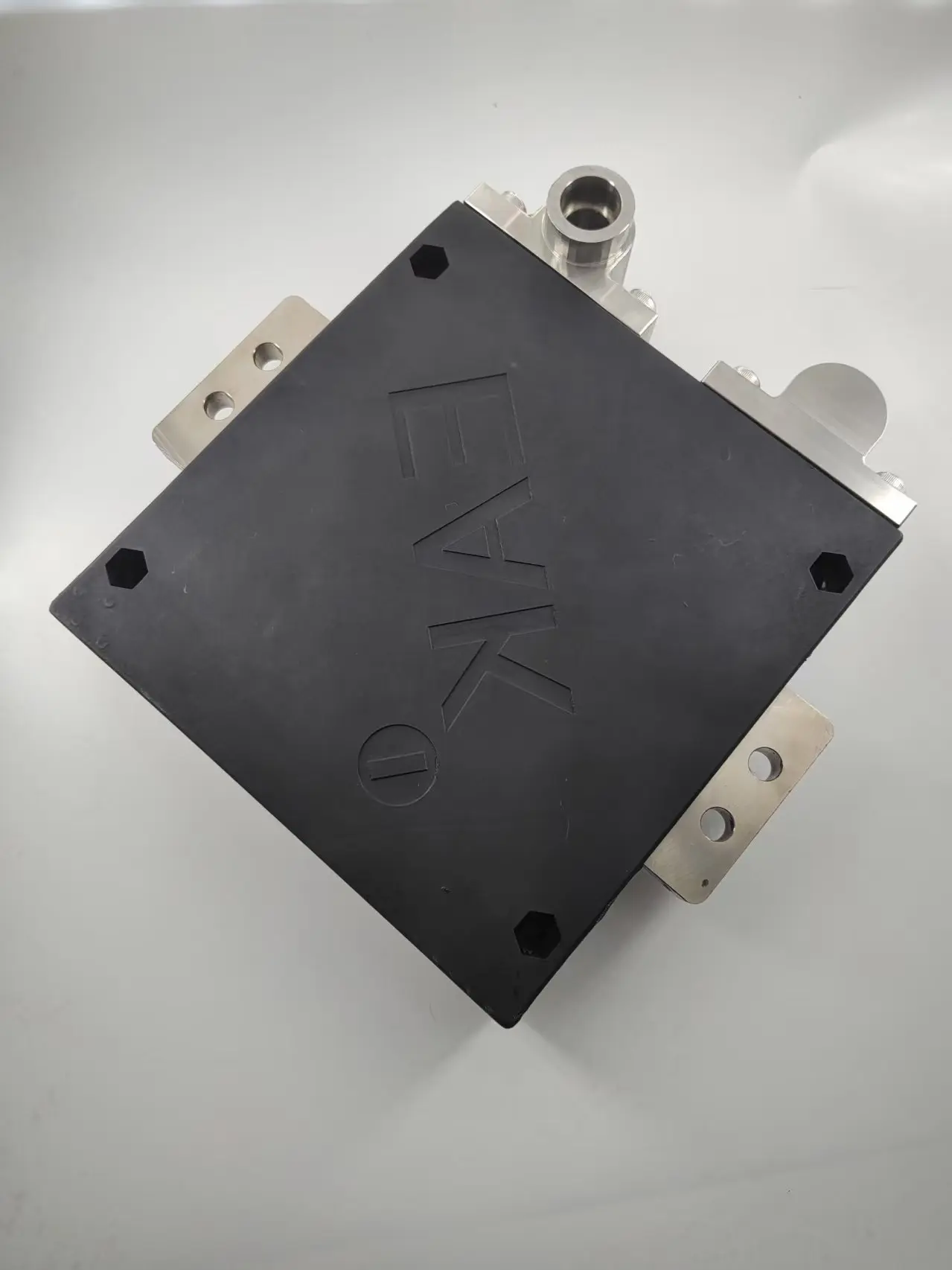

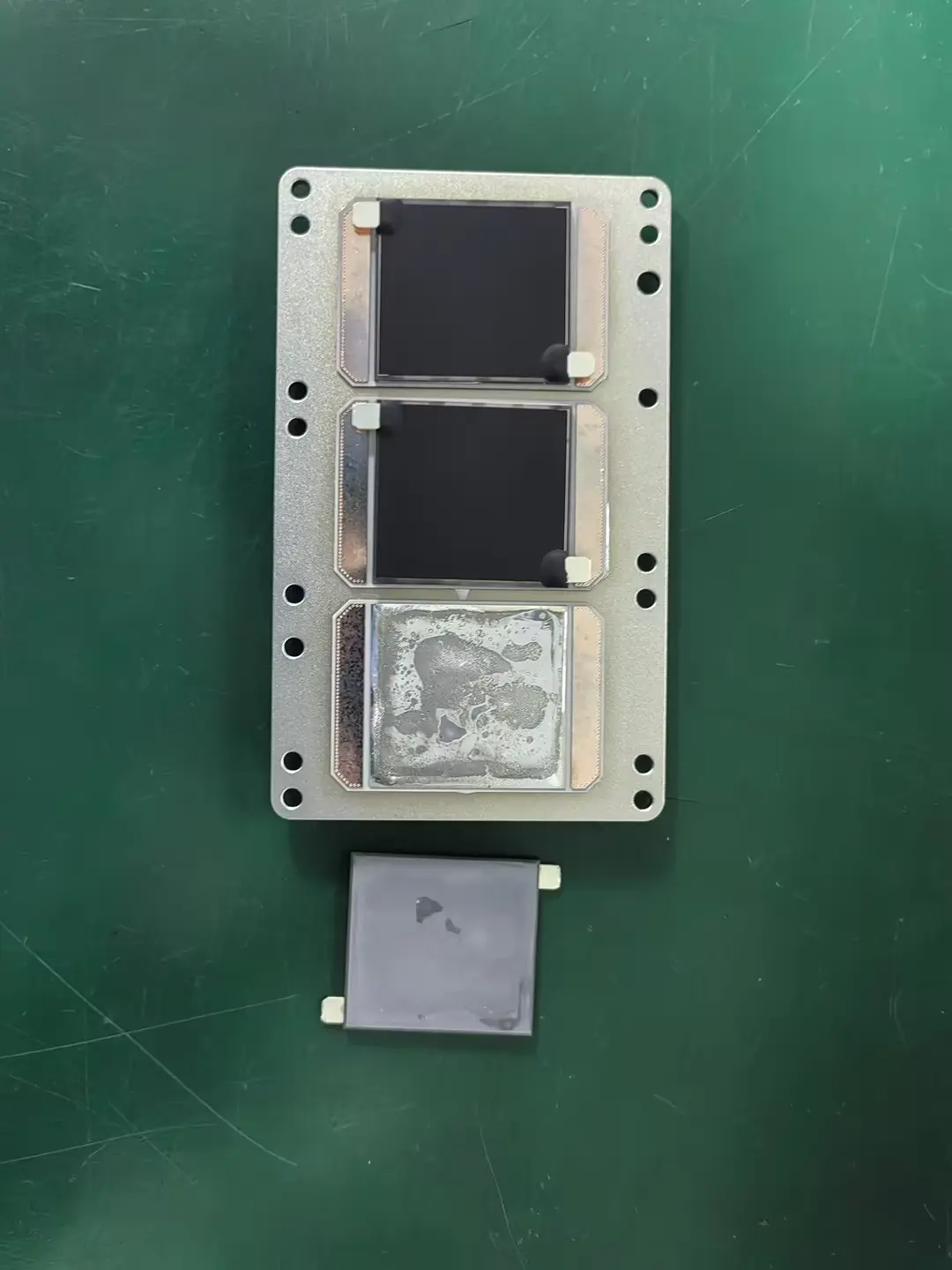

Liquid-cooled resistors are high-power resistive elements integrated into a sealed, fluid-cooled housing—typically using deionized water or dielectric coolant. When used in chopper-controlled circuits, they offer three key advantages:

- Superior Thermal Management Liquid cooling removes heat 10–50x more efficiently than air, enabling resistors to handle continuous loads of 10 kW, 50 kW, or even higher in compact footprints. This is crucial in 48V data center power validation, EV dynamometer testing, and industrial braking systems where space and thermal headroom are limited.

- Stable Performance Under Load Unlike air-cooled alternatives, liquid-cooled resistors maintain consistent resistance values even during prolonged operation, ensuring accurate power dissipation and system stability—critical for repeatable test results or safe braking.

- Scalability and Reliability With no moving parts and robust construction (often using AlN or ceramic substrates with thick-film elements), liquid-cooled resistors offer long service life in harsh environments. Their modular design also allows easy scaling for multi-kilowatt applications.

Real-World Applications

- Regenerative Braking in Industrial Drives: When motors decelerate, they feed energy back into the DC bus. A chopper circuit detects overvoltage and activates a liquid-cooled braking resistor to safely dissipate excess power—preventing inverter damage.

- Programmable Electronic Loads for 48V Systems: In data center power testing, engineers use chopper-controlled liquid-cooled resistors to simulate dynamic server loads. The chopper’s duty cycle adjusts the effective load in real time, while liquid cooling handles the heat from sustained high-current tests.

- Battery and Fuel Cell Validation: High-power test benches use this combination to emulate real-world discharge profiles with precision and thermal safety.

Conclusion: The Future Is Cooled—and Controlled

As power densities rise and efficiency standards tighten, the integration of liquid-cooled resistors with chopper circuits is no longer optional—it’s essential. This combination merges the precision of solid-state switching with the thermal robustness of liquid cooling, enabling safer, smaller, and smarter power systems.

Whether you’re designing a braking unit for a mining conveyor or validating a 48V server power architecture, choosing the right liquid-cooled resistor ensures your chopper system performs reliably under the most demanding conditions.

Ready to upgrade your power dissipation strategy? Explore our range of high-efficiency liquid-cooled resistors engineered for chopper-based applications—and turn excess energy into controlled performance.