When it comes to high-power electronics — from EV fast chargers and industrial motor drives to laser power supplies and rail traction systems — thick film resistors are no longer just passive components. They’re becoming the thermal backbone of next-generation power modules. And with innovations like liquid cooling, aluminum nitride (AlN), and even synthetic diamond substrates, today’s thick film resistors are breaking power density barriers once thought impossible.

Why Thick Film? Why Now?

Thick film resistor technology — where conductive paste (often ruthenium oxide-based) is screen-printed onto ceramic substrates and fired at high temperatures — offers unique advantages for high-power applications:

✅ Planar design ideal for integrated cooling ✅ Low inductance for high-frequency switching ✅ Laser-trimmable for precision resistance values ✅ Excellent mechanical stability under vibration

But traditional alumina (Al₂O₃) substrates limit thermal performance. That’s where advanced materials and cooling methods come in.

Liquid-Cooled Thick Film Resistors: Power Without the Heat

By embedding microfluidic channels directly into the resistor package, liquid-cooled thick film resistors can continuously dissipate 500W to 5,000W+ while maintaining temperature rises under 15°C. Coolant — typically deionized water or glycol mix — flows through sealed channels, transferring heat away at unprecedented efficiency.

Applications:

- Braking resistors in electric trains

- Dummy loads in power supply testing

- DC bus discharge in solar inverters

- Pulsed power in medical defibrillators

Thermal Game-Changer: AlN Substrates

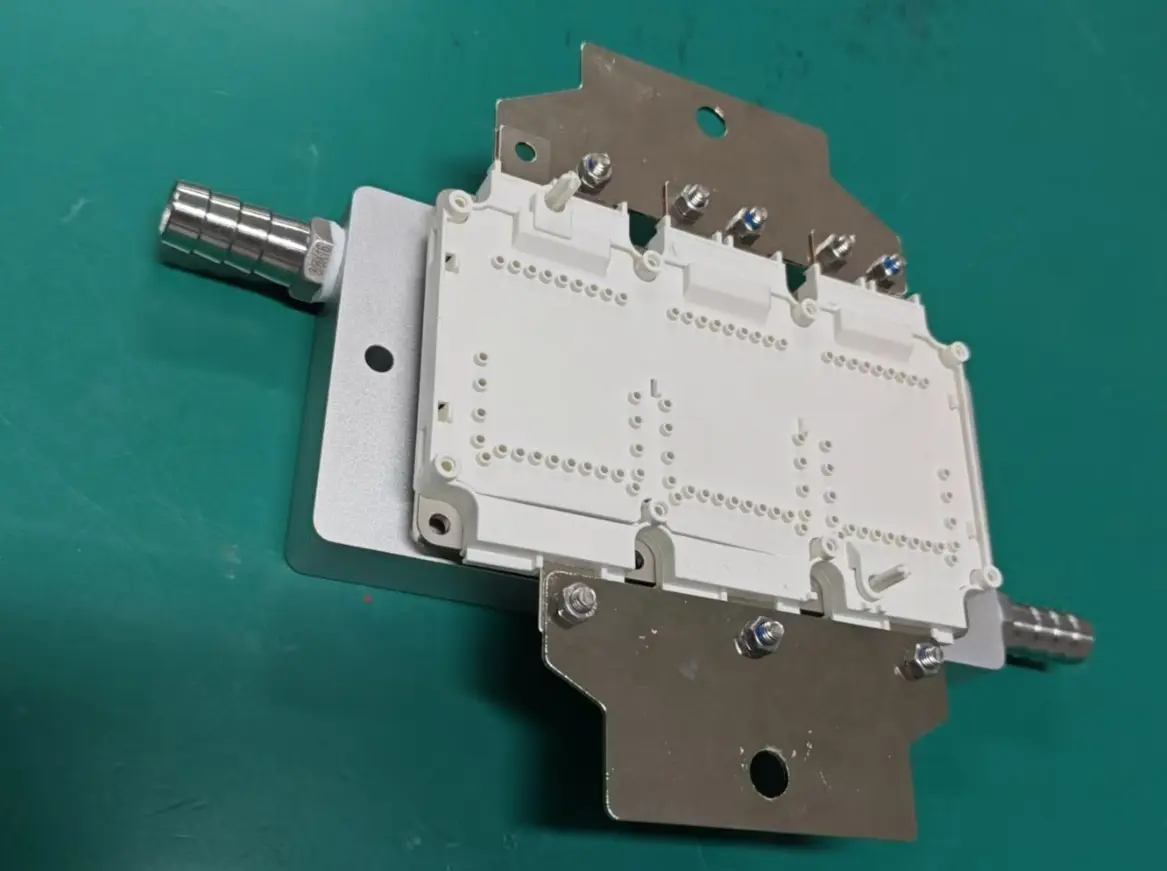

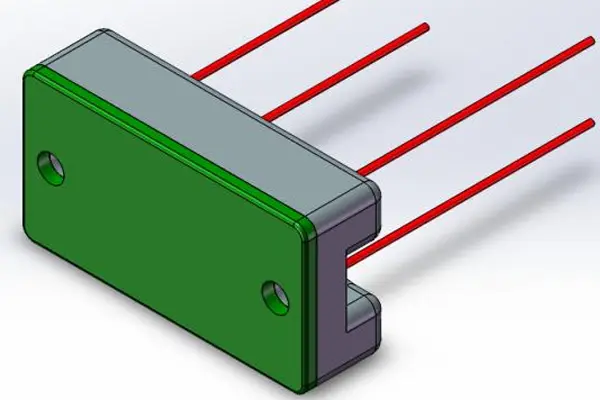

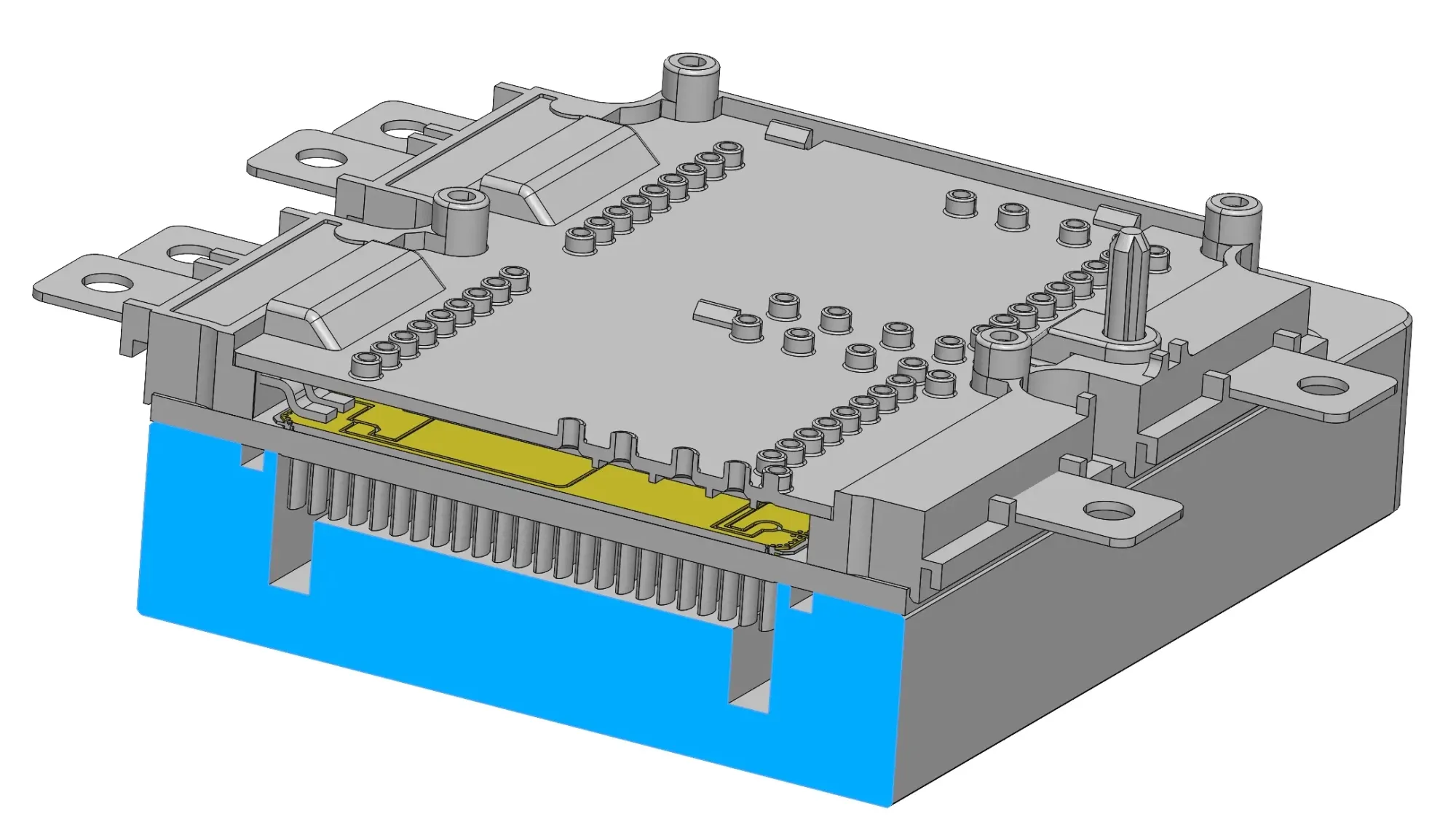

Internal structure of a liquid-cooled thick-film resistor(Product development phase: HPD module encapsulation mode is used)

Internal structure of a liquid-cooled thick-film resistor(Product development phase: HPD module encapsulation mode is used)

Aluminum Nitride (AlN) substrates boast thermal conductivity of 170–220 W/m·K — nearly 8x that of standard alumina. When paired with thick film resistors, AlN enables:

- Lower thermal resistance (<0.02°C/W)

- Higher continuous power ratings in smaller footprints

- Better reliability under thermal cycling

Perfect for automotive, aerospace, and telecom power systems demanding compact, robust solutions.

The Ultimate Edge: Diamond Substrate Thick Film Resistors

For mission-critical, ultra-high-power systems, synthetic diamond substrates offer thermal conductivity exceeding 2,000 W/m·K — surpassing copper. Benefits include:

- Near-instantaneous heat spreading (no hot spots)

- Ultra-low coefficient of thermal expansion (CTE)

- High dielectric strength (>10 kV/mm)

- Chemical inertness for harsh environments

Though premium-priced, diamond-based thick film resistors are gaining traction in:

- High-energy physics labs

- Military radar and pulsed power

- 800V+ EV charging infrastructure

- Industrial laser cutting systems