In today’s rapidly evolving technological landscape, high-power testing is becoming increasingly critical across a range of industries—from aerospace to defense and marine engineering. One key component that enables these advanced systems to be tested safely and effectively is the liquid-cooled resistor (LCR). This powerful yet compact solution has become indispensable for absorbing massive amounts of energy during testing procedures.

What Are Liquid-Cooled Resistors?

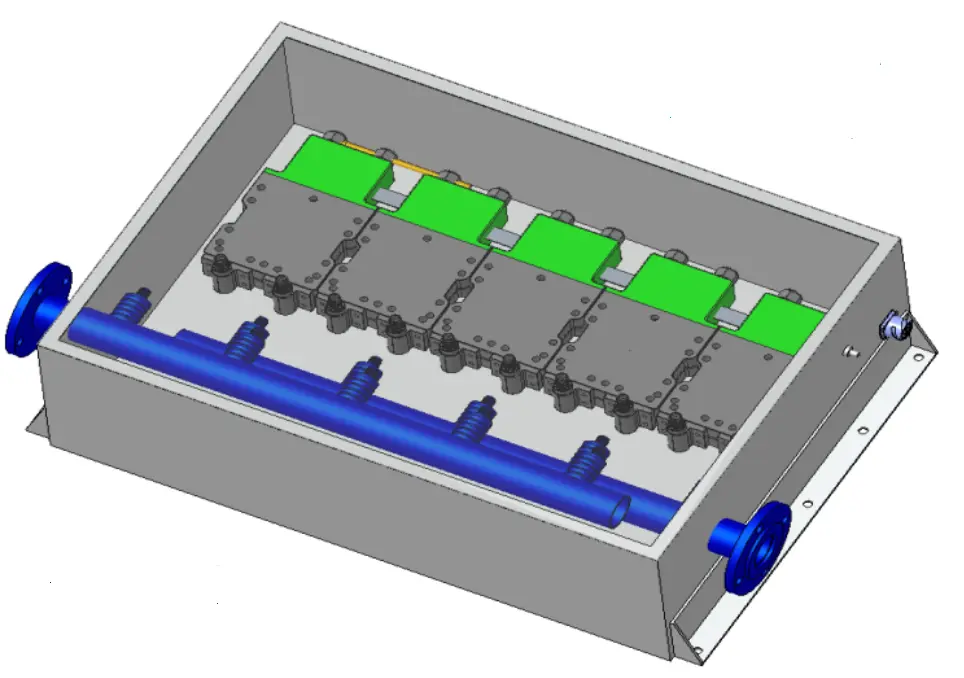

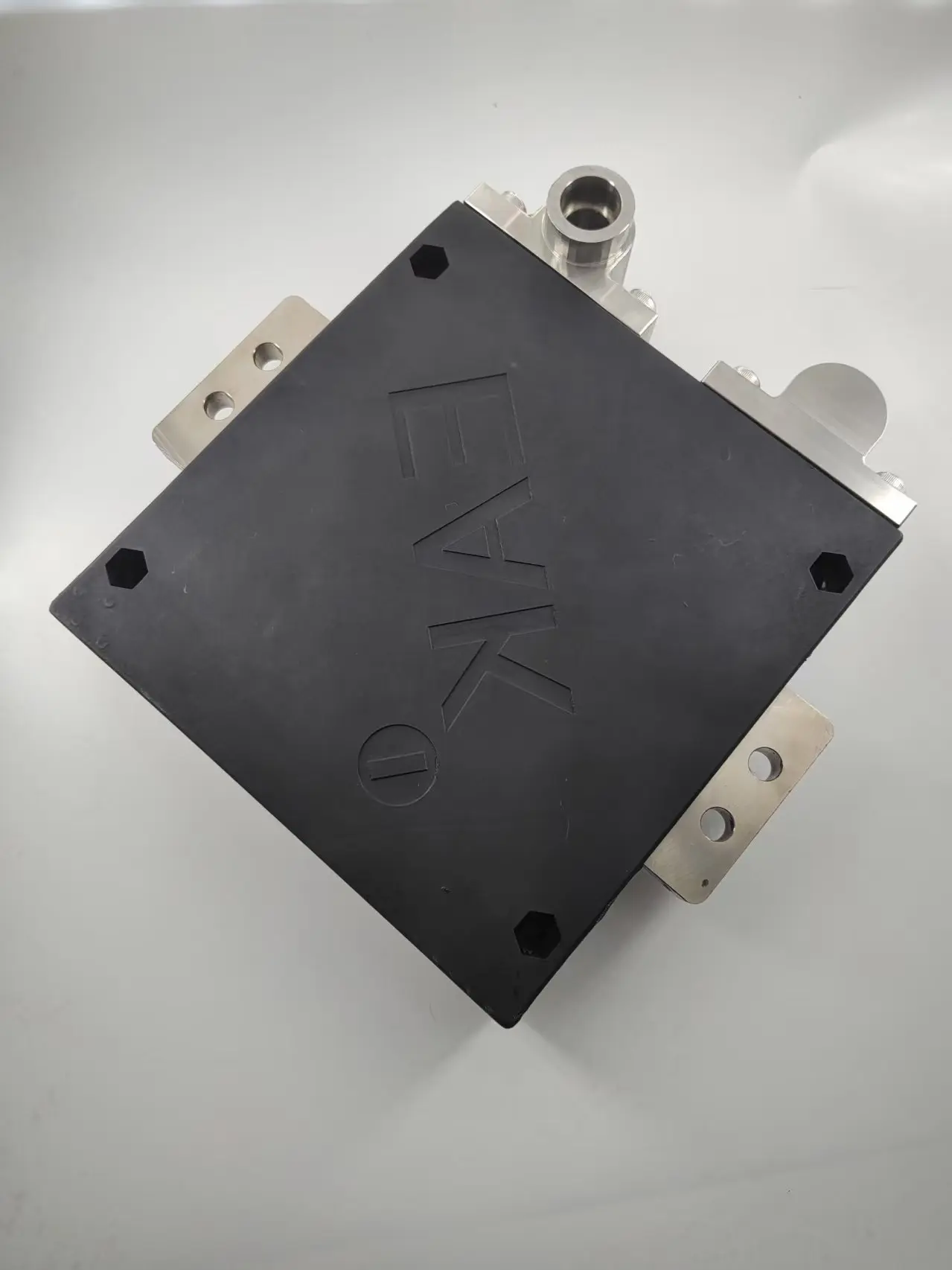

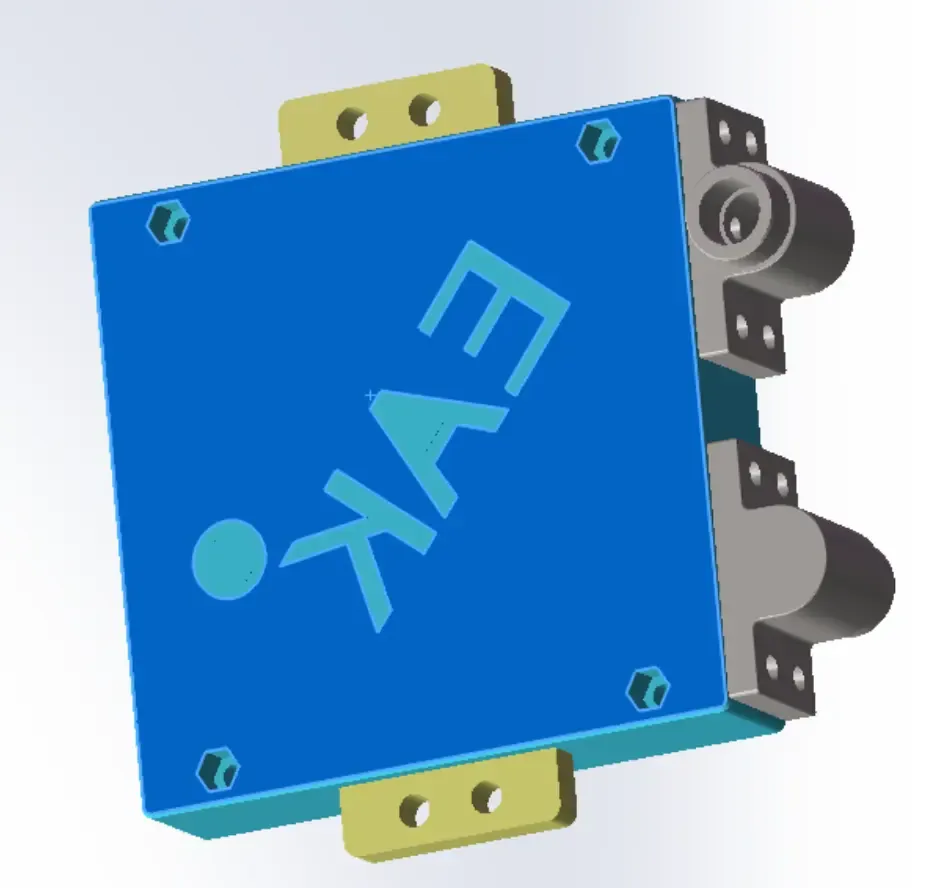

Liquid-cooled resistors are specialized electrical components designed to dissipate large quantities of power by using liquid—typically water or a water-glycol mixture—as a cooling medium. Compared to traditional air-cooled resistors, they offer significantly higher power density with lower weight and smaller footprint, making them ideal for applications where space and efficiency are crucial.

Liquid Cooled Resistors

Liquid Cooled Resistors

Liquid-Cooled Resistors in Electric and Hybrid Aircraft Ground Testing

As the aviation industry moves toward electrification, testing electric and hybrid propulsion systems becomes essential. These tests often involve high-voltage, high-current motors and inverters that must be validated under real-world conditions before flight.

During such ground tests, it’s necessary to simulate the actual load the motor would encounter in operation. This requires a test load capable of absorbing megawatt-level power , which is where liquid-cooled resistors come into play. Their ability to handle extreme power levels without overheating makes them the preferred choice over air-cooled alternatives, especially when minimizing weight and size is important.

Moreover, the use of liquid cooling allows for more consistent thermal management, ensuring stable performance during long-duration tests and reducing the risk of equipment failure due to overheating.

Marine Power Systems and Shipboard Integration Testing

The maritime sector faces similar challenges when testing integrated power systems for modern ships. Large naval vessels and commercial ships increasingly rely on electric propulsion systems, which require rigorous testing before deployment.

Testing high-power shipboard motors, generators, and energy storage systems demands a load bank that can absorb hundreds of kilowatts to multiple megawatts of power. In such environments, liquid-cooled resistors provide an efficient and reliable solution. Their compact design and high thermal efficiency make them well-suited for confined spaces like ship engine rooms.

Additionally, water cooling aligns naturally with the existing infrastructure on many vessels, simplifying integration and maintenance. As navies worldwide invest in next-generation all-electric ships, the demand for robust and scalable LCR-based test systems will continue to rise.

Directed Energy Weapons and Laser Test Systems

One of the most cutting-edge applications of liquid-cooled resistors is in the field of directed energy weapons (DEWs), including high-energy lasers and microwave systems. These technologies represent the future of defense systems, offering precision, speed, and cost-effective engagement capabilities.

However, testing DEW systems presents significant thermal and electrical challenges. During development and validation phases, engineers need to simulate operational loads while managing the immense heat generated. Liquid-cooled resistors serve as critical test loads, allowing engineers to measure system performance accurately while safely dissipating the energy.

In laser weapon testing, for example, the resistor may be used to absorb reflected or unused energy from the beam. This ensures not only accurate measurements but also protects sensitive components from damage. The superior thermal conductivity of liquid cooling allows for rapid heat removal, enabling continuous and repeatable testing cycles.

Why Choose Liquid-Cooled Resistors?

There are several compelling reasons why liquid-cooled resistors are the go-to solution for high-power testing:

- High Power Density : They can handle extremely high power levels in a relatively small package.

- Efficient Thermal Management : Water cooling provides faster and more uniform heat dissipation than air cooling.

- Compact and Lightweight : Especially beneficial in mobile or space-constrained applications like aircraft and ships.

- Scalability : Multiple units can be connected in parallel or series to meet varying power requirements.

- Reliability : Designed for long-term, high-intensity use in industrial and military-grade environments.

Conclusion

From electric aircraft testing to naval power systems and next-generation defense technologies, liquid-cooled resistors are playing a pivotal role in enabling safe, efficient, and realistic high-power testing. As power levels continue to increase across industries, so too will the reliance on this innovative technology.

Whether you’re developing a new propulsion system or testing the latest in laser weaponry, integrating liquid-cooled resistors into your test setup could be the key to success. Stay ahead of the curve with high-performance, high-reliability solutions tailored for tomorrow’s toughest challenges.