In today’s rapidly advancing world of electronics and power systems, thermal management has become a critical factor in ensuring the longevity and performance of components. One of the most innovative solutions to emerge is the EAK liquid-cooled resistor , which incorporates cutting-edge PINFIN water channel technology with double-sided water cooling . This advanced design not only enhances heat dissipation but also addresses many of the challenges faced by traditional resistors. When combined with graphite composite materials, serpentine designs, friction stir welding, and silicon nitride ceramic heat sinks , EAK’s liquid-cooled resistors set a new standard for efficiency, reliability, and durability.

What Makes EAK Liquid-Cooled Resistors Stand Out?

1. PINFIN Water Channel Design for Superior Cooling

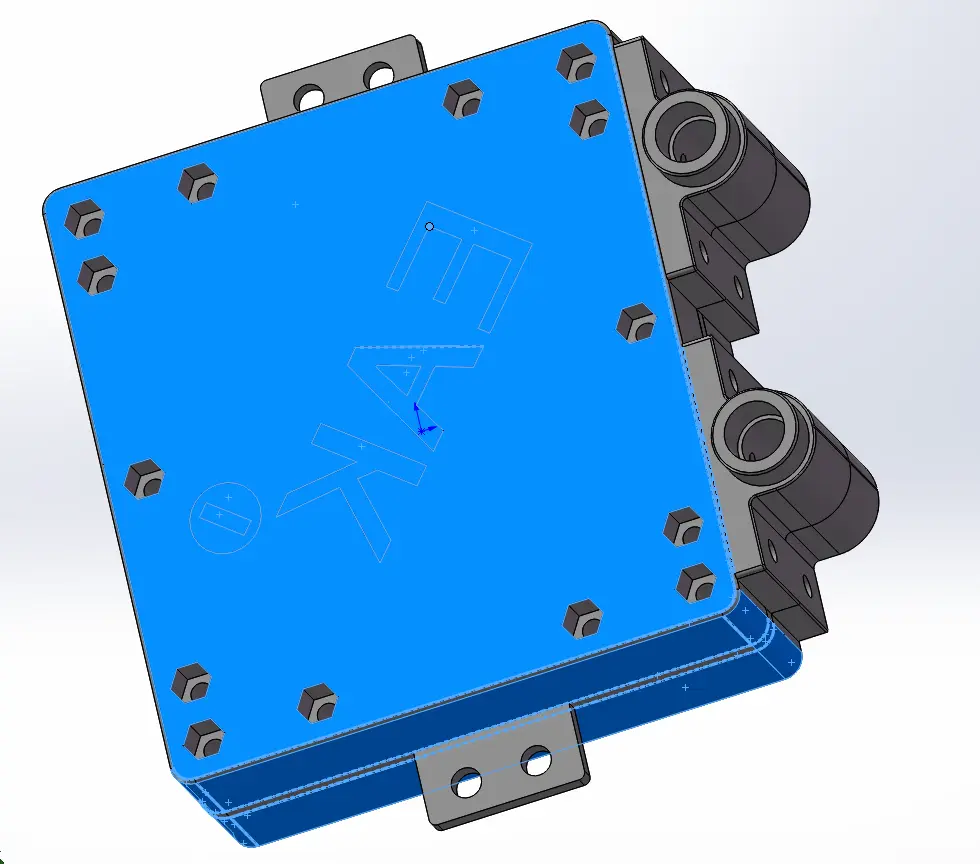

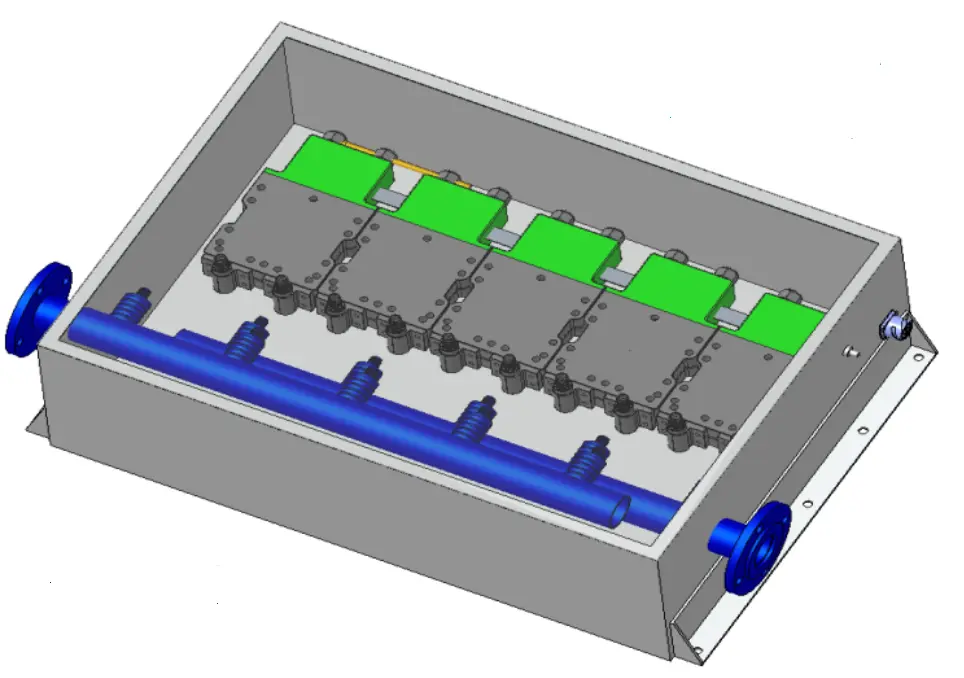

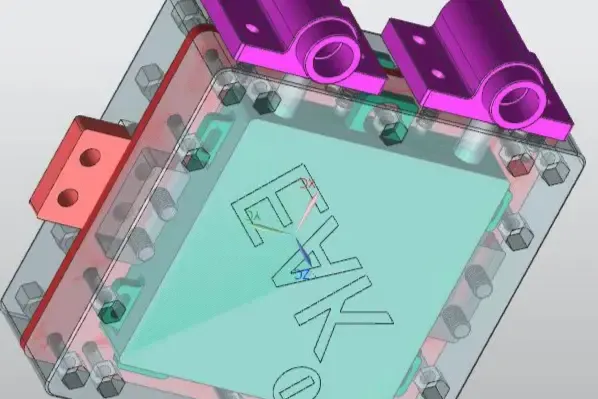

At the heart of EAK’s liquid-cooled resistors lies its revolutionary PINFIN water channel system . Unlike conventional single-sided cooling methods, this technology employs double-sided water cooling , maximizing the surface area exposed to the coolant. By efficiently dissipating heat from both sides of the resistor, the PINFIN design ensures consistent temperature regulation even under high-power loads. This feature is particularly beneficial in applications such as electric vehicles (EVs), renewable energy systems, and industrial machinery where overheating can lead to catastrophic failures.

The PINFIN structure itself is engineered to optimize fluid dynamics within the channels. Its unique fin-like protrusions create turbulence in the coolant flow, enhancing thermal transfer rates and preventing stagnant zones that could otherwise result in hotspots. As a result, users experience improved performance and extended operational lifespans for their equipment.

2. Graphite Composite Material for Enhanced Resistance Properties

Another standout feature of EAK’s liquid-cooled resistors is the use of graphite composite materials . These materials are chosen for their exceptional electrical resistance characteristics, lightweight nature, and superior thermal conductivity. Graphite composites provide an ideal balance between mechanical strength and thermal stability, making them perfect for demanding environments.

Moreover, graphite’s inherent ability to withstand high temperatures without degradation ensures that the resistor remains reliable over long periods of use. This material choice also contributes to reducing the overall weight of the resistor, which is crucial for applications like aerospace and automotive industries where every gram counts.

3. Serpentine Design Minimizes Heat Imbalances

Heat distribution plays a vital role in the functionality of any resistor. Uneven heating can cause stress on the component, leading to premature failure or reduced efficiency. To combat this issue, EAK has implemented a serpentine design in its resistors. This winding pattern evenly spreads out the generated heat across the entire surface area, minimizing localized hotspots and promoting uniform thermal dissipation.

Liquid-Cooled Resistors

Liquid-Cooled Resistors

The serpentine layout works hand-in-hand with the PINFIN water channels to ensure that no part of the resistor is subjected to excessive thermal strain. This thoughtful engineering approach not only improves the resistor’s lifespan but also enhances its performance under varying load conditions.

4. Friction Stir Welding Prevents Coolant Leakage

One of the biggest concerns with liquid-cooled systems is the potential for leaks, which can compromise safety and damage sensitive electronic components. EAK addresses this challenge through the use of friction stir welding (FSW) during the manufacturing process. FSW is a solid-state joining technique that creates seamless, leak-proof connections between the water channels and the resistor housing.

Compared to traditional welding methods, FSW produces stronger bonds with minimal distortion or porosity. This ensures that the coolant remains securely contained within the system, eliminating the risk of leakage and maintaining optimal cooling performance throughout the resistor’s lifecycle.

5. Silicon Nitride Ceramic Heat Sinks Boost Toughness and Thermal Conductivity

To further enhance the thermal management capabilities of its resistors, EAK integrates silicon nitride ceramic heat sinks into the design. Silicon nitride ceramics are renowned for their excellent combination of toughness and thermal conductivity. They offer significantly higher fracture resistance compared to other ceramic materials, making them highly durable in harsh operating conditions.

Additionally, the high thermal conductivity of silicon nitride allows it to efficiently absorb and transfer heat away from the resistor core. This not only aids in maintaining lower operating temperatures but also reduces thermal cycling stresses, thereby extending the component’s service life.

Applications of EAK Liquid-Cooled Resistors

The versatility and advanced features of EAK’s liquid-cooled resistors make them suitable for a wide range of industries and applications, including:

- Electric Vehicles (EVs): Managing regenerative braking energy and motor control systems.

- Renewable Energy Systems: Regulating power output in wind turbines and solar inverters.

- Industrial Machinery: Providing robust braking and dynamic load management in heavy-duty equipment.

- Aerospace and Defense: Ensuring reliable operation in extreme environments.

Why Choose EAK Liquid-Cooled Resistors?

When searching for a water-cooled resistor , it’s essential to consider factors such as thermal efficiency, durability, and ease of integration. EAK’s resistors excel in all these areas thanks to their innovative technologies and meticulous design. Whether you’re working on cutting-edge EV projects or developing next-generation renewable energy solutions, EAK’s liquid-cooled resistors deliver unmatched performance and peace of mind.

By leveraging advancements like PINFIN water channels, graphite composites, serpentine designs, friction stir welding, and silicon nitride ceramics, EAK has established itself as a leader in the field of thermal management. Investing in these state-of-the-art resistors means investing in the future of your business—where efficiency meets reliability.

Conclusion

As the demand for high-performance electrical systems continues to grow, so does the need for effective thermal management solutions. EAK’s liquid-cooled resistors represent a significant leap forward in addressing these needs. With their groundbreaking PINFIN water channel technology , graphite composite materials , and silicon nitride ceramic heat sinks , these resistors are designed to handle the most challenging applications while delivering unparalleled results.

If you’re looking for a water-cooled resistor that combines innovation, durability, and efficiency, look no further than EAK. Embrace the future of thermal management today!