The Role of Water-Cooled Braking Resistors in Heavy-Duty Dump Trucks: Managing Long Downhill Descents

In the demanding world of heavy-duty dump trucking, particularly on long downhill stretches, the management of braking systems is crucial for safety, efficiency, and vehicle longevity. One innovative solution to this challenge is the application of water-cooled braking resistors, which have been specifically designed to cope with scenarios where traditional braking methods might fail or become inefficient.

Understanding the Challenge

Heavy-duty dump trucks, especially those navigating long downhill routes like a 100-kilometer descent, face significant thermal and mechanical stress on their braking systems. Traditional friction brakes can overheat, leading to brake fade, reduced stopping power, and potential catastrophic failure. Additionally, in electric or hybrid vehicles, where the motor can act as a generator to recharge the battery during braking (regenerative braking), problems occur when the battery is fully charged or when the vehicle’s speed or conditions are not conducive to recharging.

Water-Cooled Braking Resistor Technology

Water-cooled braking resistors provide an alternative method for dissipating the excess kinetic energy transformed into electrical energy during downhill travel. Here’s how they work:

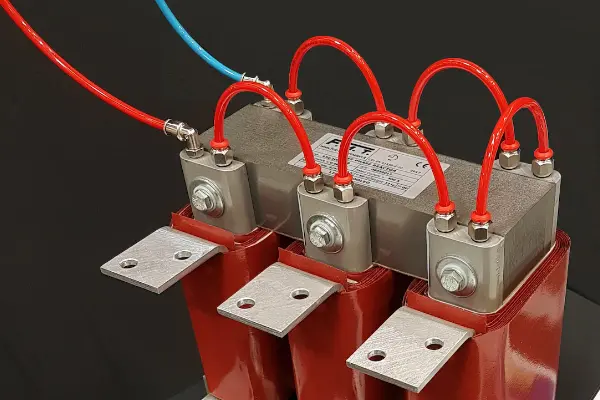

Energy Dissipation: When the vehicle is braking and the battery cannot accept more charge, the electric motor continues to generate electricity from the kinetic energy. Without a place to store this energy, it needs to be dissipated to avoid damaging the motor or the battery. Braking resistors convert this electrical energy into heat.

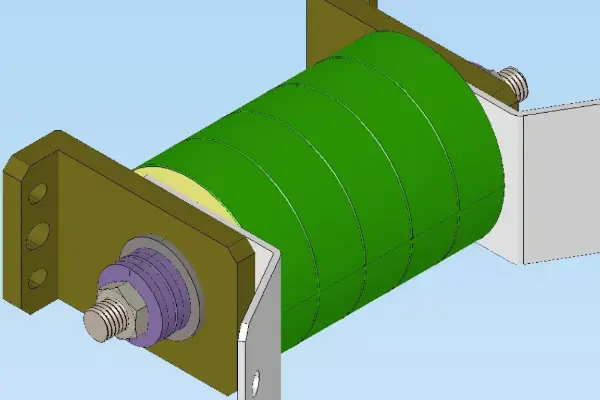

Cooling Mechanism: Unlike air-cooled resistors which might struggle with the volume of heat generated over long distances, water-cooled systems use liquid coolant to manage this heat more effectively. Water has a higher heat capacity than air, allowing for better thermal management. The heat from the resistor is transferred to the coolant, which is then cooled either through a radiator system or by direct evaporation, depending on the design.

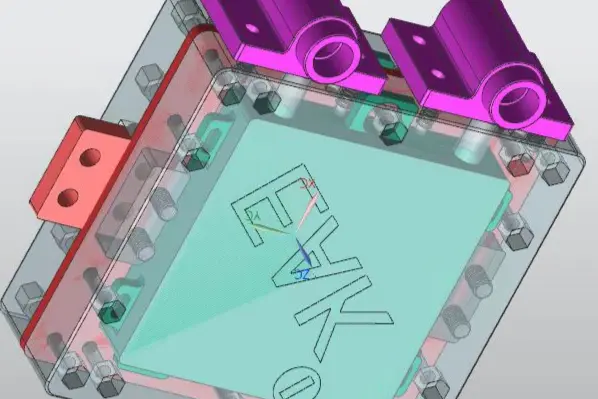

Design Suitability: These resistors are typically installed in a way that they can handle continuous operation over long periods. The design might include a large surface area for cooling or a high flow rate of coolant to ensure that the resistor does not overheat, even under heavy load conditions.

Real-World Application

In the context of a 100-kilometer downhill stretch:

Temperature Management: Over such a distance, traditional braking methods would struggle with heat accumulation. Water-cooled resistors maintain a much lower temperature, ensuring the braking system remains efficient throughout the descent.

Safety and Reliability: The consistent performance of water-cooled systems reduces the risk of brake failure, which is paramount in scenarios involving heavy loads on steep declines. This reliability can prevent accidents, particularly when dealing with the momentum of a fully loaded dump truck.

Economic Benefits: While the initial cost might be higher, the reduction in brake wear and the potential to extend the life of other vehicle components translate into long-term savings. Also, less frequent brake maintenance is required, which cuts downtime and maintenance costs.

Environmental Impact: By reducing the need for frequent brake pad replacements, water-cooled braking systems can contribute to less waste and pollution from brake dust. Moreover, in electric or hybrid trucks, this method of energy management helps in maintaining optimal battery health, which can affect the vehicle’s environmental footprint.

Challenges and Considerations

Installation and Maintenance: The system requires careful design consideration, including the placement of the cooling system, the capacity of the coolant reservoir, and the efficiency of the heat exchange. Maintenance involves regular checks of coolant levels and system integrity.

Coolant Management: The type of coolant used, its environmental impact, and the system’s design to prevent leaks are critical. Any coolant leak could have significant environmental implications, especially in remote or ecologically sensitive areas.

Adaptation to Conditions: The system must be robust enough to handle varying environmental conditions like temperature, humidity, and road conditions, which might affect cooling efficiency.

Conclusion

Water-cooled braking resistors represent a technological advancement that significantly enhances the safety and operational efficiency of heavy-duty dump trucks on long downhill stretches. By effectively dissipating energy that cannot be regenerated back into the battery, these systems help maintain vehicle control, protect against brake failure, and contribute to cost efficiencies over the vehicle’s lifecycle. As the industry moves towards more sustainable and safer operations, such innovations play a pivotal role in meeting those objectives.