When the generator is normally shut down and disconnected from the power grid, the excitation system receives a shutdown command from the computer monitoring system. The excitation regulator adjusts the control angle of the silicon-controlled rectifier (SCR) to be greater than 90°, causing the three-phase full-wave rectification circuit of the excitation power cabinet to switch from rectification mode to inversion mode. At the same time, after the generator is disconnected, the synchronous magnetic field suddenly weakens. According to Lenz’s law and self-induction phenomena, both the rotor and stator of the generator generate currents in the same direction as before. However, during rectification, the rotor behaves like a load, while during inversion, it behaves like a power source.

Although the direction of the current in the circuit does not change, the reference frame does, resulting in an equivalent back electromotive force (EMF) generated across the rotor, which is not the essence of demagnetization during inversion. Many literature sources explain it this way, but it is not entirely accurate; the primary reason is that the completeness of the circuit allows for work to be done and energy to be dissipated as heat. Consequently, the direction of energy flow changes, and this excess energy is consumed through work and heating within the generator’s stator. This process generally lasts about 5 seconds. If the generator terminal voltage exceeds 10% of the rated voltage (Un) during this 5-second period, the excitation system will report an inversion failure.

During the power generation process of the generator, abnormal tripping may occur due to reasons such as protection or malfunctions of the demagnetization switch (e.g., unintended tripping). At this moment, the magnetic circuit of the generator suddenly disconnects, causing the internal synchronous magnetic field to weaken abruptly. This results in changes to the internal rotor dynamics, preventing the release of energy within the rotor (which can be understood from the perspective of shaft dynamics or from the standpoint of dΦ/dt, where energy cannot change abruptly; both interpretations are valid). Consequently, positive and negative overvoltages can occur in the generator’s excitation circuit.

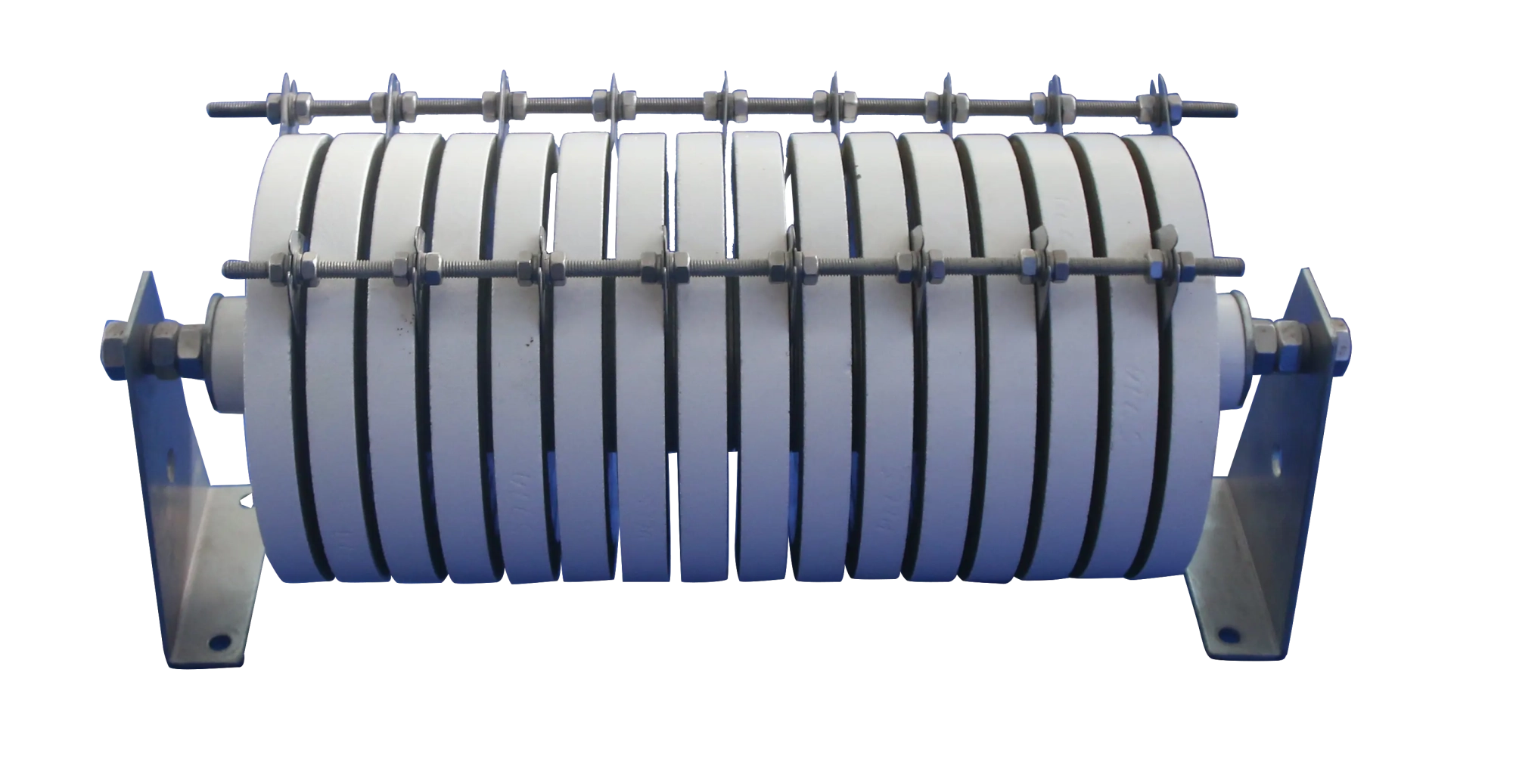

To prevent overvoltage from damaging the rotor insulation, an energy dissipation circuit must be connected across the terminals of the generator’s excitation system after the demagnetization switch trips. This energy dissipation circuit is referred to as the “nonlinear resistor demagnetization” circuit. The demagnetization circuit is typically set up within the demagnetization switch cabinet of the excitation system and consists of either “ZnO nonlinear resistors + linear resistors” or “SiC nonlinear resistors + linear resistors.” To avoid the demagnetization circuit being activated during normal power generation, a bypass connector (diode to reverse current) is connected in parallel with the excitation DC side circuit. This bypass connector controls the activation and deactivation of the energy dissipation circuit.

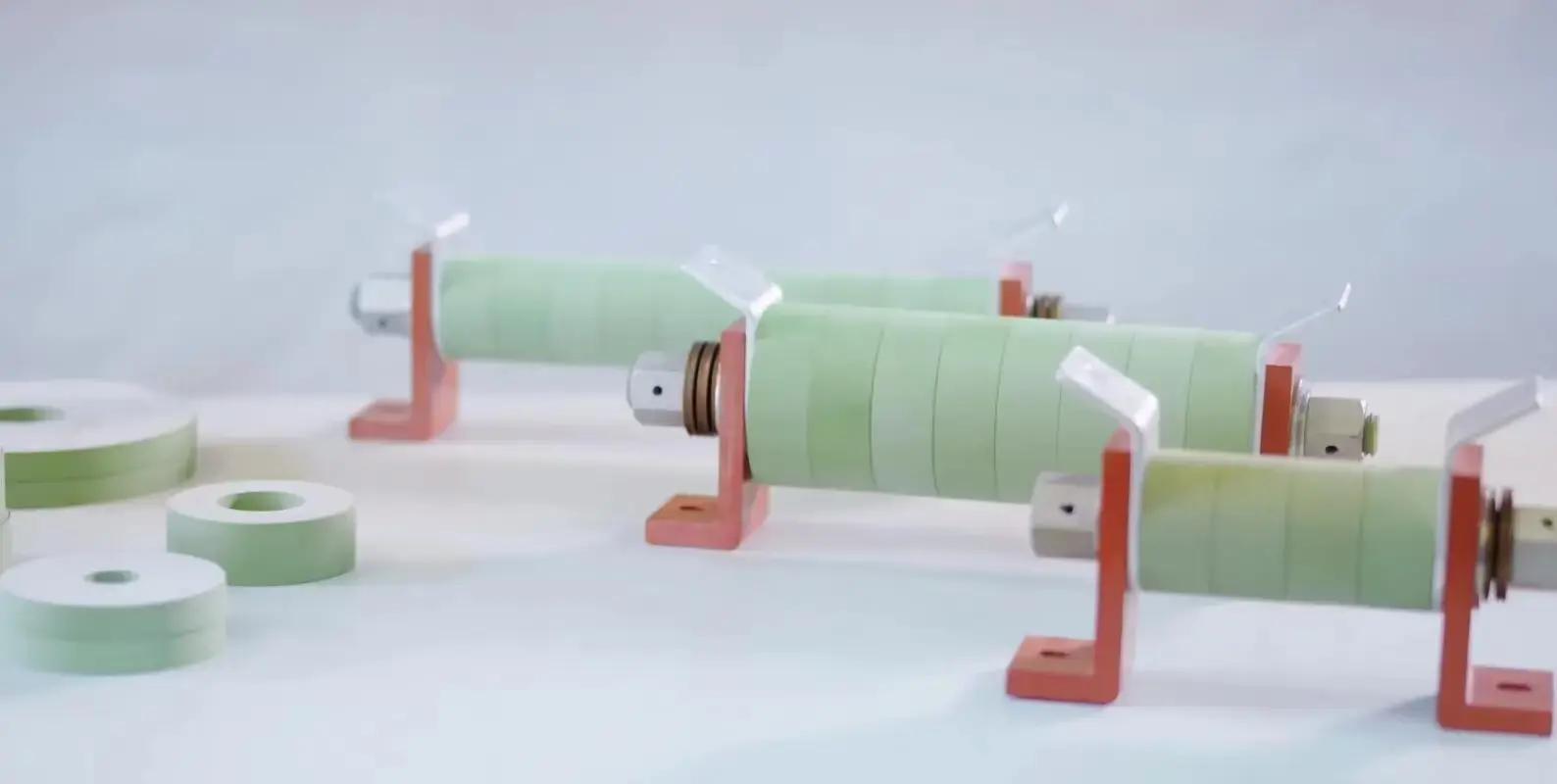

The difference between ZnO and SiC nonlinear resistors

The nonlinear coefficient of ZnO resistors is smaller than that of SiC resistors, making ZnO more suitable for absorbing overvoltages, while SiC is more suitable for energy dissipation. The leakage current of ZnO resistors is smaller than that of SiC resistors, resulting in lower power consumption of ZnO resistors in non-operating states. The performance of ZnO resistors is more affected by temperature, leading to a shorter lifespan. ZnO resistors are less effective in energy dissipation compared to SiC resistors, so to absorb the same amount of heat, the volume of SiC components needs to be smaller.