In critical applications across power electronics, aerospace, defense systems, and high-speed semiconductor testing, the demands placed on resistors are rapidly exceeding the limitations of traditional metal alloys. These environments require components capable of absorbing instantaneous, massive pulse energy, enduring sustained high heat from continuous power, and maintaining high-frequency signal integrity. The new SiC Electrically Conductive Ceramic material, featuring ultra-low resistivity as low as 10^{-7}Ωm and the inherent extreme stability of Silicon Carbide, is emerging as the superior material choice for overcoming these performance bottlenecks.

Section 1: Product Foundation – The Unique Combination of SiC Properties

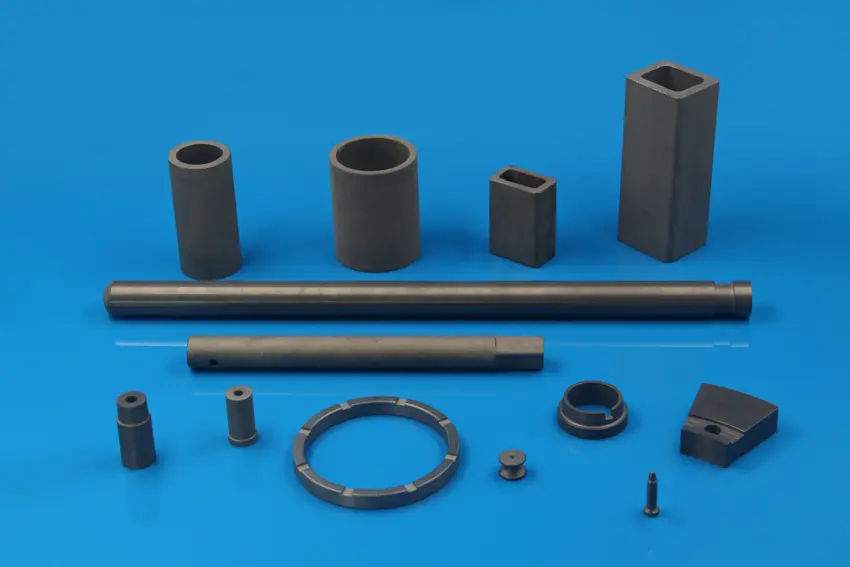

Our SiC conductive ceramic is not a conventional resistive material but a functional advanced ceramic that integrates superior electrical, thermal, and mechanical advantages. This material effectively merges near-metallic electrical conductivity with the structural durability of Silicon Carbide.

| Key Performance Advantage | SiC Conductive Ceramic Trait | Advantage Over Traditional Materials |

|---|---|---|

| Extreme Conductivity | Ultra-Low Resistivity: 10^{-7} Ω m | Minimizes energy loss and parasitic effects in high-current and high-frequency applications. |

| Thermal Management | High Thermal Conductivity & 1400^\circ C Endurance | Allows for rapid heat dissipation, stabilizing resistance values, and preventing thermal runaway. |

| Structural Stability | Exceptional Hardness & Excellent Thermal Shock Resistance | Guarantees long service life and resistance to deformation under intense thermal cycling and stress. |

| Environmental Immunity | Strong Acid/Alkali Resistance, Plating-Free | Suitable for harsh chemical environments; ensures cleanliness by eliminating surface coating contamination. |

Section 2: Core Applications – Solving Three Extreme Load Challenges

This SiC conductive ceramic is the foundational material for high-performance resistors tailored for three critical industrial operating modes:

1. High-Pulse Energy Dissipation (High-Pulse Resistors)

- Application Requirement: Power systems and high-voltage pulse generators require resistors to safely absorb large, transient energy surges within nanoseconds or microseconds.

- Material Fit: SiC ceramic exhibits outstanding thermal shock resistance and high structural integrity. This allows the resistor body to instantaneously convert massive pulse current into heat and dissipate it without fracturing or structural damage, ensuring system reliability during critical high-energy events.

2. High-Power Continuous Loading (High-Power Resistors)

- Application Requirement: Industrial induction heating, power inverters, and EV braking systems demand resistors maintain performance stability under prolonged high-temperature and high-current conditions.

- Material Fit: SiC’s high thermal conductivity is crucial, efficiently transferring the sustained heat generated by the resistor. Combined with the material’s ultra-high temperature limit, this minimizes resistance drift during long-term operation, significantly extending component lifespan.

3. High-Frequency Circuit Termination (High-Frequency Resistors)

- Application Requirement: Radar, high-speed communication, and RF systems require termination resistors with extreme precision and minimal parasitic effects to maintain signal integrity.

- Material Fit: The low dielectric loss characteristic of the ceramic, coupled with the 10^{-7} Ω m ultra-low resistivity, ensures that SiC resistors exhibit minimal parasitic inductance and capacitance in GHz-level high-frequency applications, making them ideal for precise and stable load termination.

Section 3: Primary Target Markets

This SiC conductive ceramic material is key to achieving performance breakthroughs in the following high-technology sectors:

- Power & Energy: Used in HVDC transmission systems, PV/Wind inverters, and EV charging stations for high-performance surge protection and energy braking resistors.

- Defense & Communication: Core components for radar pulse generators, high-power microwave equipment termination loads, and matching resistors.

- Precision Industry: Precision load components and probe matching resistors in high-speed semiconductor testing equipment.

SiC Conductive Ceramics offer engineers a combination of electrical performance, thermal management, and mechanical stability unattainable by traditional materials. By adopting SiC conductive ceramics, companies can design and manufacture more reliable, durable, and efficient High-Frequency, High-Power, High-Pulse Resistors, driving technological innovation in these demanding fields.