In advanced electronics, industrial heating, and high-reliability sensing systems, the demand for components that combine metal-like electrical conductivity with ceramic-grade resilience has never been greater. Enter the SIC electrically conductive ceramics resistor—a next-generation functional material engineered from silicon carbide (SiC) that redefines what’s possible in conductive ceramics.

Unlike traditional insulating ceramics or corrosion-prone metal resistors, SIC electrically conductive ceramics resistors deliver ultra-low electrical resistivity—down to 10⁻⁷ Ω·m—while maintaining exceptional mechanical strength, thermal stability, and chemical inertness. This unique combination makes them ideal for applications where failure is not an option.

Unmatched Material Properties

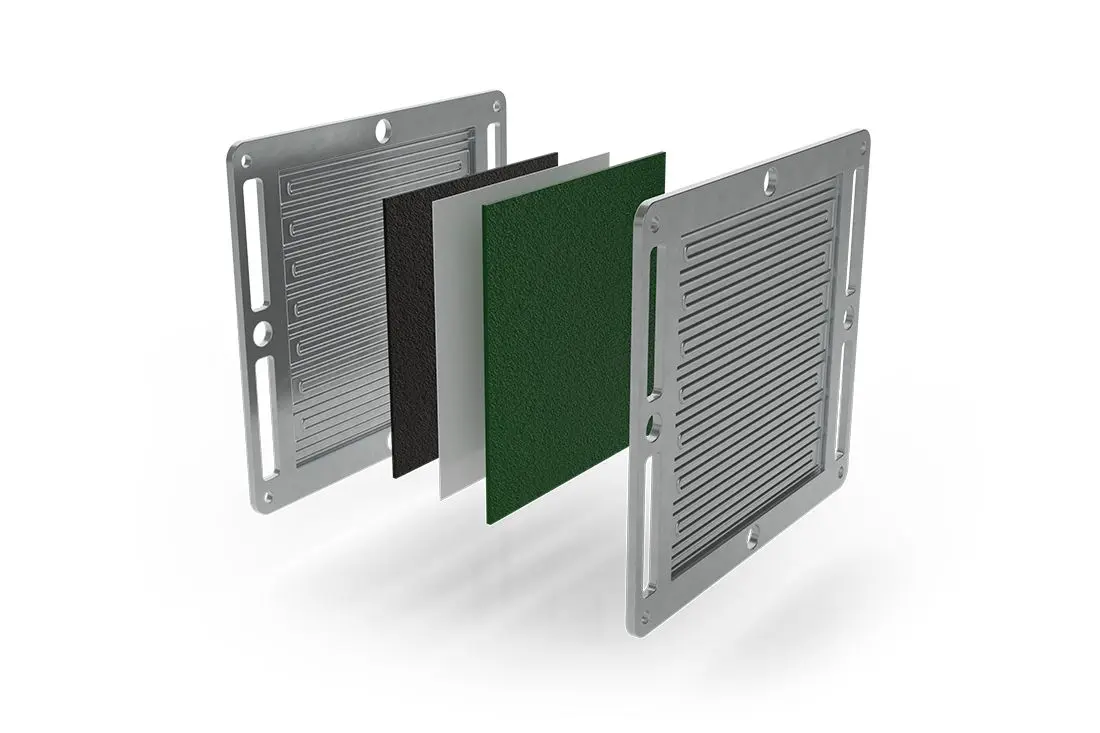

SIC electrically conductive ceramics resistors are fabricated through precision ceramic processing techniques such as injection molding, dry pressing, or isostatic pressing, using high-purity conductive SiC powders. The resulting components exhibit:

- Ultra-low resistivity (as low as 10⁻⁷ Ω·m) for efficient current conduction

- High bending strength (

300 MPa) and hardness (20 GPa) for structural reliability - Excellent fracture toughness for impact resistance in dynamic environments

- Full corrosion resistance—no plating required, even in acidic, alkaline, or saline conditions

- Thermal stability up to 1400°C, enabling use in extreme-temperature applications

Moreover, for heating applications, the resistivity can be precisely tailored across a wide range: 10⁻⁵ to 10⁻¹ Ω·m, allowing engineers to optimize power output, voltage requirements, and thermal response for specific designs.

Dual Functionality: Conduction + Heating

SIC electrically conductive ceramics resistors are available in two primary functional categories:

- Ultra-Low Resistance Conductive Components Designed for signal transmission, grounding, or electrical contact in harsh environments. Common in medical sensors, wearable electronics, and automotive systems, these resistors provide stable, maintenance-free conductivity where metals would corrode or degrade.

- Self-Heating Resistive Elements Functioning as integrated heating resistors, these components convert electrical energy directly into uniform, controllable heat. With fast thermal response, high energy efficiency, and intrinsic safety (no open flames or aging effects), they outperform conventional PTC or MCH heaters—especially in low-voltage systems (e.g., 5V or 12V) used in consumer and medical devices.

Both types can be manufactured in a wide range of geometries—pins, sheets, tubes, needles, or complex custom shapes—enabling seamless integration into compact or high-density assemblies.

Key Application Areas

Thanks to their multifunctional nature, SIC electrically conductive ceramics resistors are widely adopted across high-growth industries:

- Medical & Wearable Electronics: ECG electrodes, charging contacts for smartwatches, and implantable sensor interfaces benefit from biocompatibility, sweat resistance, and long-term signal stability.

- Consumer Health Devices: Beauty instruments, massage tools, and e-cigarettes leverage rapid, uniform heating with enhanced safety.

- Automotive & Smart Mobility: Used in cabin heating elements, battery sensors, and EV subsystems requiring corrosion-resistant electrical pathways.

- Semiconductor Manufacturing: Serve as durable, non-contaminating conductive or heating components in vacuum or corrosive process chambers.

- Industrial Systems: From pipeline heating in chemical plants to precision thermal control in metallurgy, these resistors endure where others fail.

Why Choose SIC Over Alternatives?

Traditional metal resistors suffer from oxidation, galvanic corrosion, and limited high-temperature performance. Standard ceramics, while robust, are insulators—useless for conduction. SIC electrically conductive ceramics resistors solve this dichotomy by offering:

✅ True electrical functionality in a ceramic matrix ✅ Lifetime stability in aggressive environments ✅ Design flexibility through customizable geometry and resistance ✅ Intrinsic safety for low-voltage consumer applications ✅ No need for surface coatings or maintenance

This makes them not just a component—but a system-enabling material for next-generation electronics.

Future-Ready and Scalable

As industries push toward miniaturization, electrification, and extreme-environment operation, the role of SIC electrically conductive ceramics resistors continues to expand. Emerging opportunities include integration into energy recovery systems, high-frequency snubber circuits, and even liquid-cooled high-power resistor modules—where SiC’s high thermal conductivity and electrical tunability offer compelling advantages.

Load Resistor,Snubber Resistor,Arc-suppression Resistor