This article explores the transformative capabilities of non-inductive ceramic resistors in power control applications, highlighting their superior performance, thermal stability, and versatility in demanding environments.

Key Takeaways

Non-inductive ceramic resistors stand out as pivotal components in modern power control systems, primarily due to their remarkable performance characteristics. These resistors are designed to handle high voltage and energy, providing exceptional stability and efficiency in challenging electrical environments. Notably, the absence of inductance significantly reduces the risk of voltage spikes during operations, which is crucial for applications demanding precise control over power delivery.

In comparison to traditional resistor technologies, non-inductive ceramic resistors exhibit superior thermal stability. This is especially evident in high voltage high energy resistors where heat dissipation is a critical factor; thus, their ability to maintain performance without degradation under extreme conditions becomes indispensable. Furthermore, the versatility associated with disc bulk ceramic resistors allows for deployment across various applications, from industrial motor drive systems to intricate battery testing setups.

By utilizing these advanced resistance components, engineers can enhance the reliability and lifespan of electrical systems while optimizing their functionality. As a tip for implementation: always ensure adequate cooling mechanisms are in place when integrating non-inductive ceramic resistors into your designs to further maximize their efficiency and operational lifespan.

“Harnessing the potential of non-inductive ceramic resistors allows for robust designs that cater to the demands of modern power electronics.”

Introduction to Non-inductive Ceramic Resistors: A Game Changer in Power Control

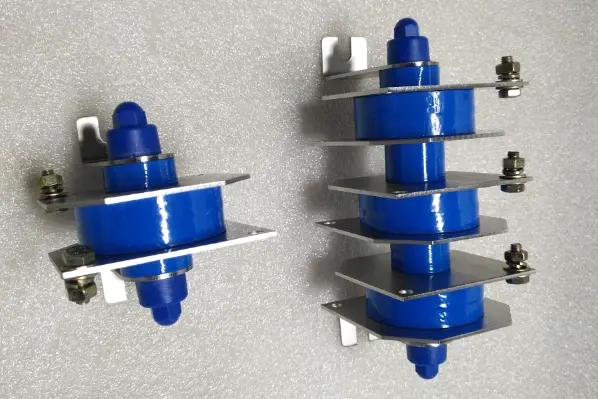

In the ever-evolving realm of power control systems, Non-inductive Ceramic Resistors have emerged as pivotal components, transforming conventional practices with their remarkable characteristics. Unlike traditional resistors, which often exhibit inductive effects that can lead to inefficiencies and overheating, Non-inductive Ceramic Resistors are engineered to operate without inducing significant inductance. This feature is particularly advantageous in applications requiring precise voltage regulation and high-frequency signal processing, where even minimal inductive influence can skew performance metrics. Their construction typically involves Disc Bulk Ceramic Resistors, known for their robust thermal stability and ability to handle high voltage and high energy conditions. As a result, these resistors are ideally suited for demanding environments where thermal management is crucial. Furthermore, the versatility of Non-inductive Ceramic Resistors allows them to function optimally across a spectrum of applications, from intricate motor drive systems to rigorous battery testing scenarios. Their capacity to maintain performance under extreme conditions underscores their importance in contemporary electrical systems, establishing them as a game changer in power control strategies worldwide. This evolution reflects a broader shift towards more reliable and efficient components in the pursuit of enhanced electrical performance and stability.

Understanding the Thermal Stability of Non-inductive Ceramic Resistors

The thermal stability of non-inductive ceramic resistors is a pivotal characteristic that distinguishes them within the realm of high voltage applications, especially in demanding environments where resistive components are routinely subjected to extreme temperature fluctuations. These resistors, engineered from advanced ceramic materials, are designed to maintain their operational integrity under thermal stress, showcasing a remarkable capacity for heat dissipation. Unlike traditional resistor technologies that can suffer from significant performance degradation when exposed to elevated temperatures, non-inductive ceramic resistors exhibit a consistent resistance value and reliability. This is particularly crucial in applications such as high voltage high energy resistors and in motor drive systems where resistive heating can lead to failures. Moreover, the absence of inductance in these ceramic variants ensures minimal energy losses and enhanced performance during rapid thermal cycling. In contrast to their disc bulk ceramic resistor counterparts, non-inductive designs provide enhanced durability while sustaining long-term operational effectiveness. As engineers continue to innovate within power control systems, harnessing the benefits offered by the thermal stability of non-inductive ceramic resistors becomes essential for devising robust electrical solutions capable of withstanding rigorous demands.

Versatility of Non-inductive Ceramic Resistors in Extreme Environments

Non-inductive ceramic resistors, particularly in the forms of disc bulk ceramic resistors, have emerged as a versatile solution for applications demanding resilience in extreme environments. Their robust construction allows them to withstand significant thermal and mechanical stresses, which is essential for high voltage high energy resistors utilized in critical power control systems. These resistors display an exceptional ability to maintain performance efficiency even under fluctuating conditions and elevated temperatures, a feature that sets them apart from traditional resistor technologies. The chemical stability of non-inductive ceramic resistors further enhances their applicability, making them suitable for use in environments that involve corrosive substances or varying humidity levels. Their low inductance property plays a crucial role in minimizing noise and ensuring stable operation within complex circuitry, particularly when used in motor drive systems or battery testing applications. This multifaceted functionality underscores the pivotal role of non-inductive ceramic resistors in modern electrical systems, particularly where reliability and precision are paramount amidst challenging operational parameters.

Applications of Non-inductive Ceramic Resistors in Motor Drive Systems

Non-inductive ceramic resistors play a pivotal role in enhancing the performance and reliability of motor drive systems, owing to their unique design and material properties. These resistors, particularly the high voltage high energy variants, are tailored to handle the demanding electrical environments encountered in motor applications. Their non-inductive nature minimizes unwanted inductive reactance, which can lead to voltage spikes and inefficiencies in control circuits. This feature is especially critical in high-efficiency drives where precision is paramount.

When integrated into motor drive systems, non-inductive ceramic resistors ensure that power control is executed with remarkable accuracy. They offer excellent thermal stability, allowing them to manage power dissipation effectively without compromising electrical performance. This stability not only prolongs the lifespan of the resistors themselves but also enhances the overall durability of the motor system by mitigating risks associated with thermal overload or erratic behavior due to temperature fluctuations.

Moreover, the versatility of disc bulk ceramic resistors further amplifies their utility in these applications. Their robust composition enables them to perform admirably across a broad range of conditions, from high-temperature environments to scenarios involving significant mechanical stress. In addition, these resistors can be customized for specific resistance values and power ratings, making them adaptable for various drive configurations—this adaptability is invaluable in modern engineering designs that favor tailored solutions for specific operational needs.

In conclusion, the integration of non-inductive ceramic resistors into motor drive systems is not merely beneficial but transformative—driving improvements in efficiency and reliability while ensuring that even under harsh conditions, performance remains uncompromised. Their unique qualities mark them as an essential component in elevating electrical system capabilities across numerous applications within industrial and commercial sectors alike.

The Role of Non-inductive Ceramic Resistors in Battery Testing

In the realm of battery testing, non-inductive ceramic resistors have emerged as indispensable components, enhancing both efficiency and accuracy in evaluating energy storage systems. These resistors exhibit minimal inductance, which is crucial for high-frequency applications commonly encountered during dynamic load tests. Unlike traditional resistor technologies, non-inductive ceramic resistors are capable of dissipating significant amounts of energy without overheating, thanks to their robust thermal stability. This characteristic allows them to manage high voltage scenarios effectively, making them particularly suitable for use in high voltage high energy resistor applications. Moreover, the construction of these components—often utilizing disc bulk ceramic materials—facilitates a reliable and durable performance even under extreme conditions. This versatility enables developers and engineers to execute a wider array of tests on battery systems, ranging from cycling tests to safety evaluations, ultimately leading to more reliable battery performance in real-world applications. Emphasizing the importance of thermal management and response time during testing procedures underscores the revolutionary capabilities offered by non-inductive ceramic resistors within this critical field.

Comparative Analysis: Non-inductive Ceramic Resistors vs. Traditional Resistor Technologies

The landscape of electrical engineering has undergone significant transformation with the introduction of non-inductive ceramic resistors, which have established themselves as superior alternatives to traditional resistor technologies. Non-inductive ceramic resistors, particularly valued for their high performance in high voltage and high energy applications, demonstrate remarkable advantages over their more conventional counterparts, such as disc bulk ceramic resistors. One of the distinguishing features of non-inductive designs is their ability to manage thermal energy effectively; they exhibit exceptional thermal stability under fluctuating conditions, which is often a critical consideration for engineers designing complex systems. Traditional resistors, depending on their material and configuration, may not provide the same resilience in high energy environments or during transient conditions. Furthermore, non-inductive ceramic resistors minimize inductive effects that can lead to unwanted oscillations in power circuits, thus ensuring a smoother operation and reduced noise levels. This reliability in performance translates into lower maintenance costs and extended service life for devices utilizing these advanced components. In contrast, traditional resistor technologies may fall short in scenarios requiring rigorous performance and durability. Such comparisons underscore the growing preference for non-inductive ceramic resistors in various applications where consistency and efficiency are paramount, positioning them as essential elements in the future of power control systems.

Future Innovations: Enhancing Performance in Power Control Applications

The evolution of power control technologies increasingly emphasizes the necessity for components that can withstand high demands without compromising performance. High Voltage High Energy Resistors serve as a critical component in this landscape, where innovation is key to addressing the challenges posed by modern electrical systems. Non-inductive Ceramic Resistors stand out due to their unique construction, which minimizes inductance and thus improves operational efficiency in high-frequency applications. Their thermal stability further enhances their appeal, allowing for reliable performance under varying temperature conditions that could otherwise impede traditional resistor technologies. With the integration of Disc Bulk Ceramic Resistors, engineers are finding new pathways to optimize circuit designs, ensuring that devices not only meet but exceed current industry standards. Emerging innovations in material sciences and manufacturing processes promise even greater advancements in these resistors’ capabilities, potentially leading to a new era where electrical systems are more resilient, efficient, and capable of handling ever-increasing power demands. As research progresses, the potential for Non-inductive Ceramic Resistors to redefine performance benchmarks in power control applications appears more achievable than ever, paving the way for breakthroughs across diverse sectors from automotive to renewable energy solutions.

Conclusion: The Transformative Impact of Non-inductive Ceramic Resistors on Electrical Systems

In the dynamic field of electrical systems, the advent of non-inductive ceramic resistors marks a significant advancement, particularly in applications requiring high voltage and energy handling capabilities. These non-inductive ceramic resistors are designed to deliver exceptional performance while maintaining thermal stability, thus enabling them to operate efficiently under demanding conditions. Their construction allows for minimal inductance, minimizing losses and enhancing power control, which is crucial for modern high voltage high energy resistors applications. Additionally, when compared to traditional resistor technologies, non-inductive ceramic resistors exhibit superior durability and versatility. This makes them ideal for use in environments where conventional resistors may falter. For instance, in scenarios involving motor drive systems or battery testing, the need for reliable power handling is paramount; here, disc bulk ceramic resistors shine with their robust characteristics. As industries continue to evolve and push the boundaries of electrical performance, the role played by non-inductive ceramic resistors is poised to become increasingly pivotal in shaping the future of innovative power control solutions.

FAQs

What are Non-inductive Ceramic Resistors? Non-inductive ceramic resistors are specialized electronic components designed to minimize inductance, making them particularly effective in high-frequency applications. Their construction typically involves resistive materials that offer high thermal stability and durability.

How do Non-inductive Ceramic Resistors compare to traditional resistors? Unlike traditional resistors, which may exhibit inductive properties that can affect performance in dynamic applications, non-inductive ceramic resistors maintain consistent resistance levels across a range of frequencies and operating conditions, making them ideal for precise power control.

What advantages do High Voltage High Energy Resistors offer? High Voltage High Energy Resistors are specifically designed to handle significant voltage and energy loads without failing. Their robust construction and materials allow them to perform optimally under high-stress conditions, which is crucial in power management applications.

Can you explain the role of Disc Bulk Ceramic Resistors in electrical systems? Disc Bulk Ceramic Resistors provide excellent thermal performance and are particularly suitable for high-temperature environments. Their unique design allows for efficient heat dissipation, ensuring reliability in demanding operational scenarios.

In what applications are Non-inductive Ceramic Resistors most beneficial? These resistors excel in various sectors including motor drive systems, battery testing, and other high-energy applications where precision and stability are paramount. Their adaptability makes them a preferred choice for engineers focused on optimizing performance.

Are Non-inductive Ceramic Resistors suitable for extreme environments? Yes, their thermal stability and resilience make non-inductive ceramic resistors highly suitable for extreme conditions, from industrial manufacturing to aerospace applications where reliable performance is essential.