As power electronics continue to push the boundaries of efficiency and miniaturization, thermal management has become a critical bottleneck. In applications ranging from electric vehicles and 5G infrastructure to aerospace and industrial laser systems, traditional air-cooled resistors simply can’t keep up. The solution? The liquid-cooled resistor—a next-generation component engineered for extreme power density, compact size, and long-term reliability.

Among the most advanced developments in this space is the thick-film liquid-cooled resistor built on a diamond-silicon carbide (Diamond-SiC) composite substrate. By combining ultra-high thermal conductivity materials, precision thick-film technology, PIN-FIN cooling, and semiconductor-style packaging, this innovative liquid-cooled resistor delivers unmatched performance where heat, space, and power collide.

Why Diamond? The Thermal Advantage

The key to this breakthrough lies in the use of diamond as the core thermal substrate. With a thermal conductivity of 1000–2000 W/(m·K)—the highest of any known solid material—diamond acts as a “thermal superhighway,” rapidly spreading and transferring heat away from the resistive layer.

When combined with silicon carbide (SiC), which offers excellent electrical insulation and mechanical stability, the resulting Diamond-SiC composite provides:

- Ultra-fast heat dissipation

- Low coefficient of thermal expansion (CTE), reducing thermal stress

- High electrical insulation for high-voltage applications

This combination allows the liquid-cooled resistor to handle power densities exceeding 50 W/cm², far beyond the limits of conventional Al₂O₃ or AlN-based resistors.

Thick-Film Resistor Layer: Precision and Durability

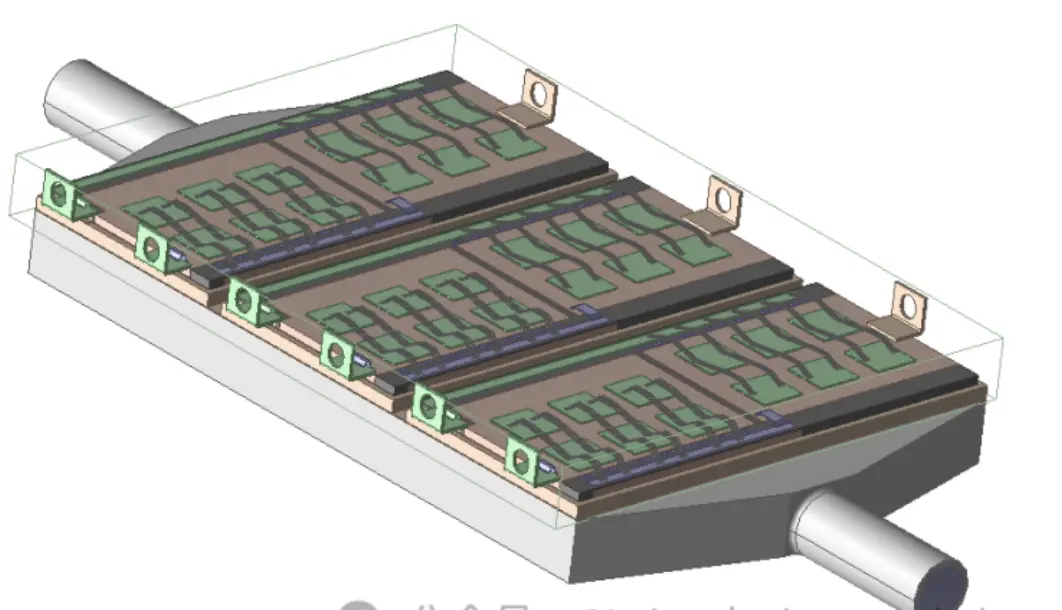

On top of the Diamond-SiC base, a thick-film resistive layer is applied using screen printing and high-temperature sintering. Materials such as ruthenium oxide (RuO₂) or bismuth-ruthenate (Bi₂Ru₂O₇) enable precise resistance values from ohms to megaohms, with low temperature coefficient of resistance (TCR < ±50 ppm/°C).

To ensure strong adhesion between the thick-film ink and the inert diamond surface, advanced surface metallization techniques—such as Cr/Ni/Au sputtering—are used. This enhances bonding strength and ensures long-term stability under repeated thermal cycling, a common challenge in high-power applications.

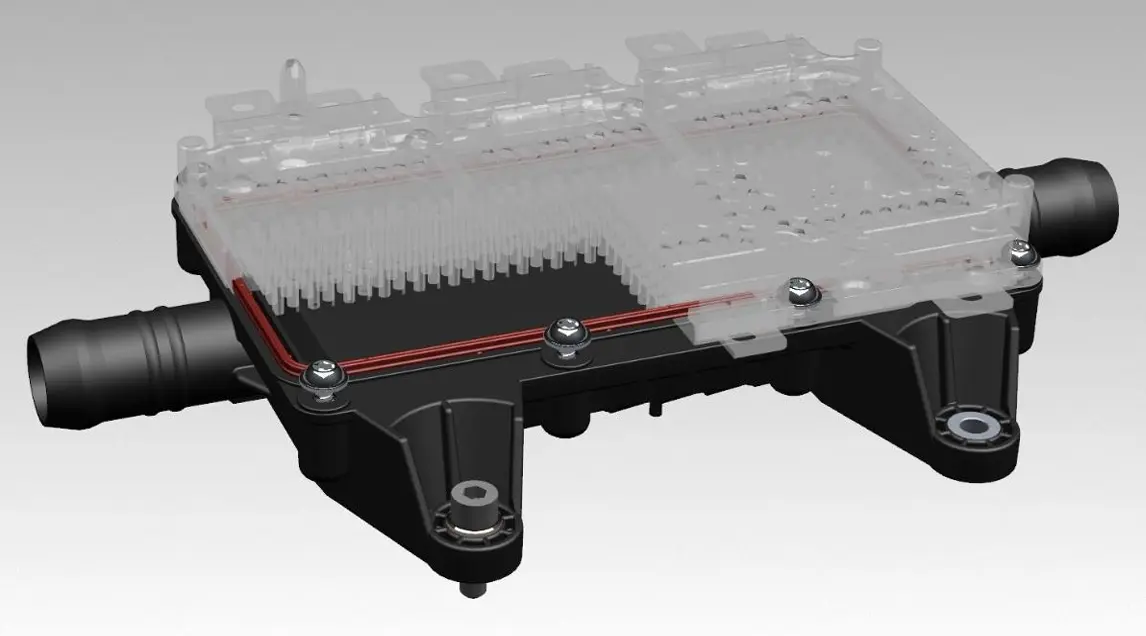

Active Cooling: PIN-FIN + Liquid Flow for Maximum Efficiency

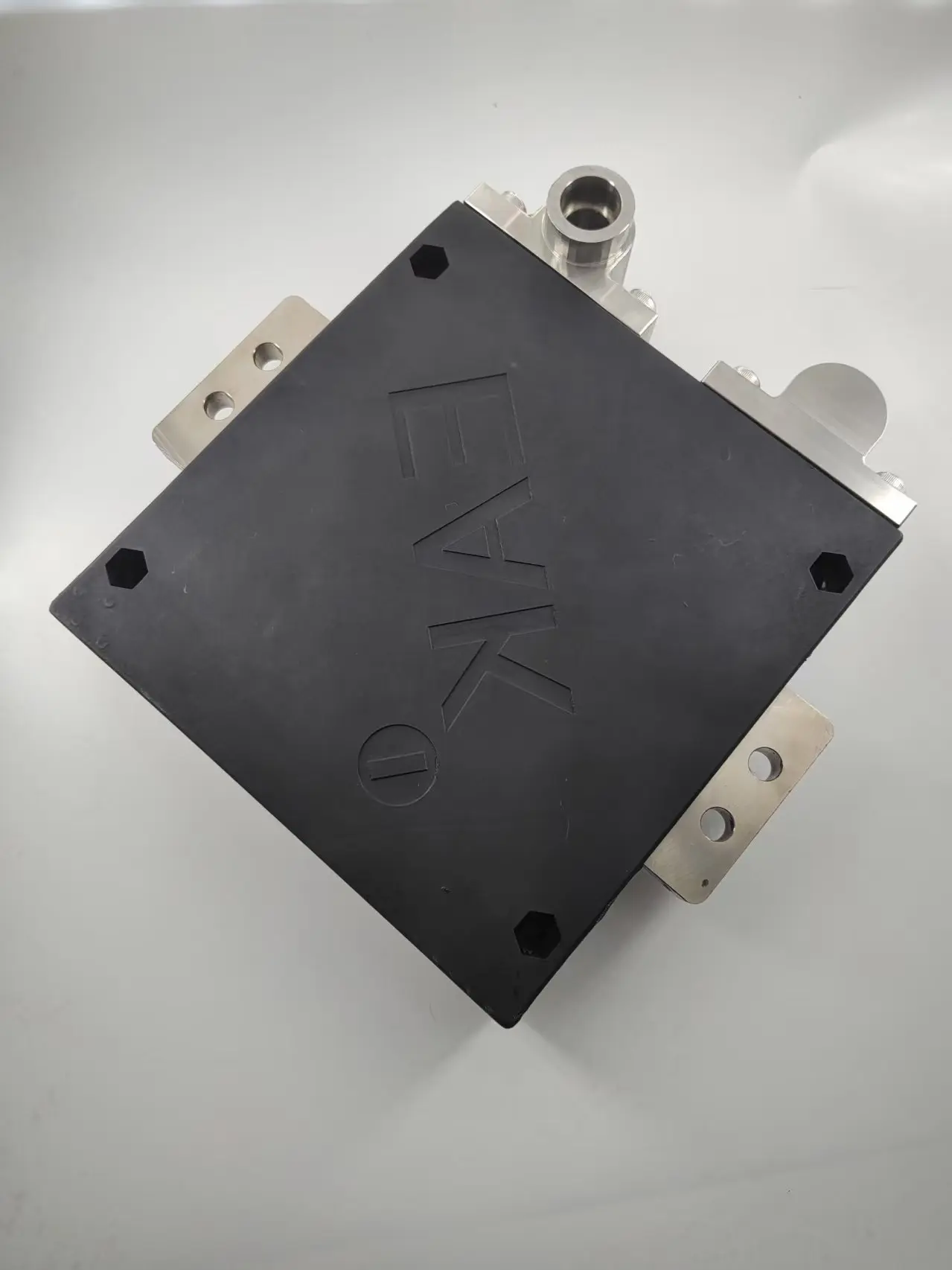

Heat generated in the resistive layer is quickly transferred through the Diamond-SiC base to a high-density copper PIN-FIN heatsink bonded via eutectic or solder technology. The entire assembly is enclosed in a sealed liquid cooling chamber, where coolant—such as deionized water or fluorinated fluid (e.g., 3M Novec)—flows through microchannels around the fins.

This liquid-cooled resistor design achieves thermal resistance as low as 0.1–0.3 °C/W, enabling continuous operation at multi-kilowatt power levels without overheating. Compared to traditional air-cooled solutions, the system volume is reduced by up to 80%, making it ideal for compact, high-performance systems.

Semiconductor-Grade Packaging: Reliability Meets Scalability

Unlike conventional power resistors, this advanced liquid-cooled resistor employs semiconductor-style packaging techniques:

- Wafer-level processing

- Hermetic sealing

- Die attach and module encapsulation

This not only improves mechanical robustness and environmental resistance (moisture, vibration, corrosion) but also enables integration with temperature sensors and control circuits for real-time monitoring and smart thermal management.

The result is a highly reliable, mass-producible module suitable for mission-critical applications in automotive, defense, and industrial sectors.

Key Applications

- Electric Vehicles: Regenerative braking energy absorption with minimal footprint

- Radar & Defense Systems: Pulse load termination in compact radar transmitters

- Laser Power Supplies: High-voltage discharge protection with stable resistance

- 5G Base Stations: Power regulation in high-density RF amplifiers

- Renewable Energy: Dynamic braking in wind turbines and SVG systems

The Future of Power Electronics

As wide-bandgap semiconductors like SiC and GaN become mainstream, the demand for equally advanced passive components grows. The liquid-cooled resistor is no longer a niche solution—it’s a necessity for next-generation power systems.

With diamond-enhanced substrates, active liquid cooling, and semiconductor integration, this technology sets a new standard in thermal performance, reliability, and miniaturization.

Conclusion The liquid-cooled resistor is transforming how engineers manage heat in high-power electronics. By leveraging diamond-SiC materials and advanced packaging, it delivers extreme performance in the smallest possible footprint. For designers facing the dual challenges of power and space, the answer is clear: go liquid-cooled.