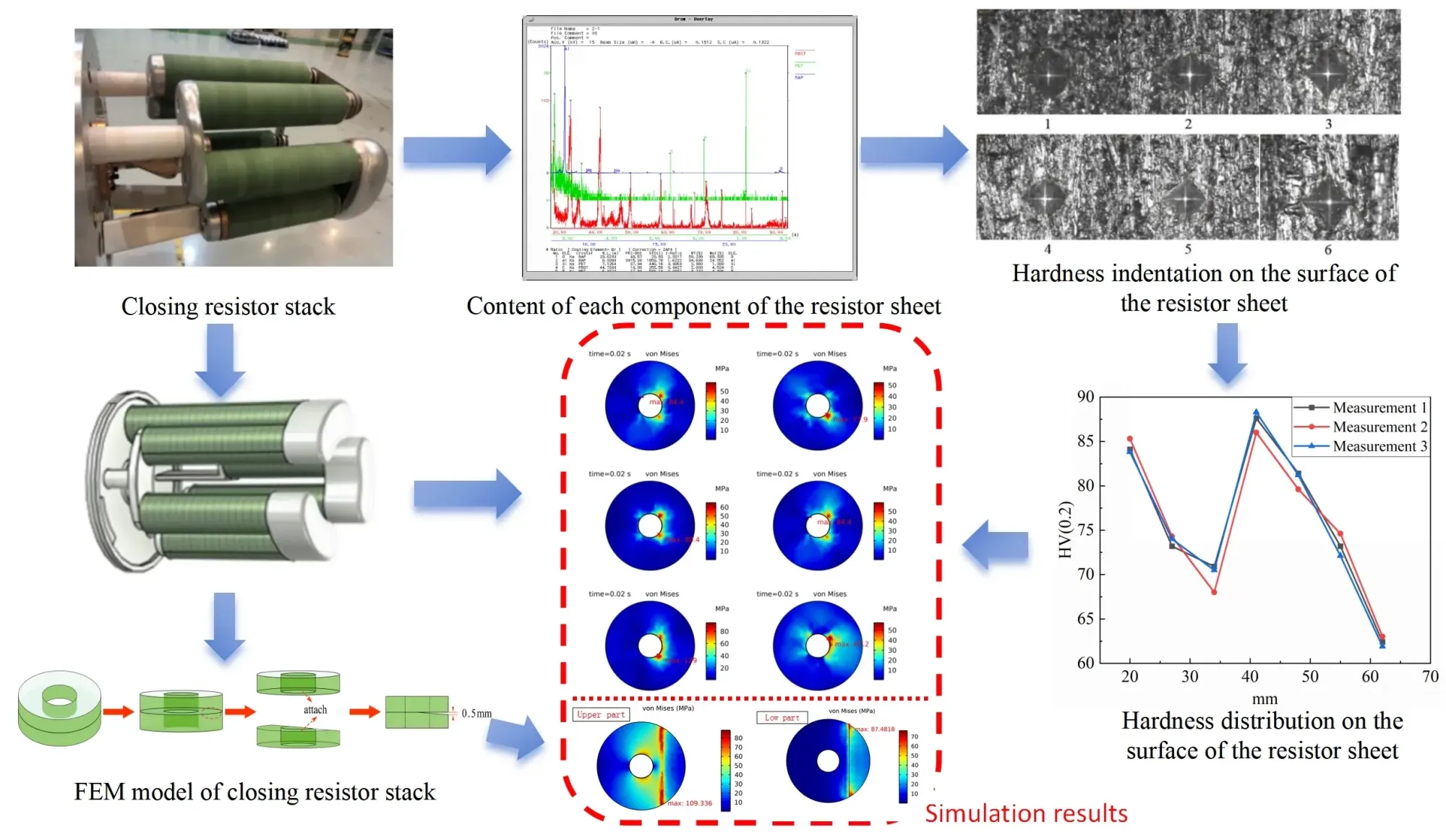

EAK prepared Mo-doped Al2O3-based ceramic/metal composites (Al2O3/Mo) using powder metallurgy methods. The effects of Mo doping on the microstructure and dielectric properties of the composites were investigated using testing and analysis methods such as X-ray diffraction and scanning electron microscopy. The results showed that the Al2O3/Mo composites were primarily composed of Al2O3 phase and Mo phase, with no new phases forming. Mo was mainly dispersed at the Al2O3 grain boundaries, and as the Mo doping amount increased, the grain size of Al2O3 gradually decreased while the porosity of the material increased. When the Mo doping content was less than 20% (mass fraction), the electrical resistivity of the composites (>10^12 Ω·cm) and the relative dielectric constant (8–9) showed no significant changes; however, when the Mo doping content exceeded 20%, Mo transitioned from a dispersed phase to a continuous phase, leading to a sharp decrease in the bulk resistivity of the composites down to 10^10 Ω·cm. When the Mo doping content reached 40%, the bulk resistivity’s decreasing trend slowed down and stabilized at around 10 Ω·cm due to the formation of a continuous conductive network of Mo within the composites. Therefore, by adjusting the Mo doping amount and phase distribution in the Al2O3 matrix, ceramic/metal composites with varying resistivities can be produced.

Ultra High-Power (over 1 kW) Resistors-Closing Resistors

Ultra High-Power (over 1 kW) Resistors-Closing Resistors

In the rectification and inversion devices of variable frequency equipment for ultra/high voltage direct current transmission and static var compensators (SVC), high-power resistor components are essential key components with broad application prospects. However, with the miniaturization and increased power requirements of these devices, current options such as wire-wound resistors are increasingly unable to meet the demands. There is an urgent need to develop a new type of compact high-power (above 1 kW) resistor component that meets the requirements for linear volt-ampere characteristics, high-temperature usage, ease of welding with metals, and efficient heat dissipation.

Currently, high-power resistor components used in electrical equipment are generally bulky, primarily wire-wound resistors, due to heat dissipation issues. For compact high-power resistors, zinc oxide (ZnO) linear resistors can currently reach up to 500 W, but further increases in power are quite challenging. Additionally, the welding technology for ZnO linear resistive materials with metals is not yet well-developed, which limits their usage. Other common ceramic composite conductive materials, such as silicon carbide (SiC), aluminum oxide (Al2O3), and graphite, also fail to meet the technical requirements for linear volt-ampere characteristics, high operating temperatures (up to 500 °C), and ease of welding with metals.

Conductive metal ceramics possess linear volt-ampere characteristics, can be used at high temperatures, are easy to weld with metals, and facilitate efficient heat dissipation, making them suitable for high-power resistor components. The commonly used conductive metal ceramics are primarily based on Al2O3. In the metallization process of existing Al2O3 ceramics, molybdenum (Mo) doping has been widely applied. The welding process of Al2O3/Mo composites with metals is mature, enabling the use of existing equipment and techniques for welding. Current reports on Al2O3/Mo composites mainly focus on their application as dielectric materials to inhibit vacuum surface flashovers, with the metal Mo content typically being less than 10%; there are relatively few reports on their use as resistive materials. Previous studies by the author indicate that when the Al2O3 content exceeds 30%, it can function as an additive to enhance the resistivity of Mo, allowing for precise control of the composite’s resistivity. Due to its conduction mechanism, which involves a continuous metal conduction pathway, it shares the same conduction mechanism as metals, thus ensuring linear volt-ampere characteristics.

For high-power resistor components, adjusting the Mo doping amount allows for the creation of ceramic-based composites with resistivities ranging from 10 to 10^12 Ω·cm. Furthermore, because Al2O3 ceramics exhibit excellent thermal shock resistance, corrosion resistance, and mechanical properties, Al2O3/Mo composites can find widespread applications as materials for high-power resistor components.

EAK prepared Mo-doped Al2O3-based ceramic/metal composites (Al2O3/Mo) using powder metallurgy methods. The effects of Mo doping on the microstructure and dielectric properties of the composites were investigated using testing and analysis methods such as X-ray diffraction and scanning electron microscopy. The results showed that the Al2O3/Mo composites were primarily composed of Al2O3 phase and Mo phase, with no new phases forming. Mo was mainly dispersed at the Al2O3 grain boundaries, and as the Mo doping amount increased, the grain size of Al2O3 gradually decreased while the porosity of the material increased. When the Mo doping content was less than 20% (mass fraction), the electrical resistivity of the composites (>10^12 Ω·cm) and the relative dielectric constant (8–9) showed no significant changes; however, when the Mo doping content exceeded 20%, Mo transitioned from a dispersed phase to a continuous phase, leading to a sharp decrease in the bulk resistivity of the composites down to 10^10 Ω·cm. When the Mo doping content reached 40%, the bulk resistivity’s decreasing trend slowed down and stabilized at around 10 Ω·cm due to the formation of a continuous conductive network of Mo within the composites. Therefore, by adjusting the Mo doping amount and phase distribution in the Al2O3 matrix, ceramic/metal composites with varying resistivities can be produced.

In the rectification and inversion devices of variable frequency equipment for ultra/high voltage direct current transmission and static var compensators (SVC), high-power resistor components are essential key components with broad application prospects. However, with the miniaturization and increased power requirements of these devices, current options such as wire-wound resistors are increasingly unable to meet the demands. There is an urgent need to develop a new type of compact high-power (above 1 kW) resistor component that meets the requirements for linear volt-ampere characteristics, high-temperature usage, ease of welding with metals, and efficient heat dissipation.

Currently, high-power resistor components used in electrical equipment are generally bulky, primarily wire-wound resistors, due to heat dissipation issues. For compact high-power resistors, zinc oxide (ZnO) linear resistors can currently reach up to 500 W, but further increases in power are quite challenging. Additionally, the welding technology for ZnO linear resistive materials with metals is not yet well-developed, which limits their usage. Other common ceramic composite conductive materials, such as silicon carbide (SiC), aluminum oxide (Al2O3), and graphite, also fail to meet the technical requirements for linear volt-ampere characteristics, high operating temperatures (up to 500 °C), and ease of welding with metals.

Conductive metal ceramics possess linear volt-ampere characteristics, can be used at high temperatures, are easy to weld with metals, and facilitate efficient heat dissipation, making them suitable for high-power resistor components. The commonly used conductive metal ceramics are primarily based on Al2O3. In the metallization process of existing Al2O3 ceramics, molybdenum (Mo) doping has been widely applied. The welding process of Al2O3/Mo composites with metals is mature, enabling the use of existing equipment and techniques for welding. Current reports on Al2O3/Mo composites mainly focus on their application as dielectric materials to inhibit vacuum surface flashovers, with the metal Mo content typically being less than 10%; there are relatively few reports on their use as resistive materials. Previous studies by the author indicate that when the Al2O3 content exceeds 30%, it can function as an additive to enhance the resistivity of Mo, allowing for precise control of the composite’s resistivity. Due to its conduction mechanism, which involves a continuous metal conduction pathway, it shares the same conduction mechanism as metals, thus ensuring linear volt-ampere characteristics.

For high-power resistor components, adjusting the Mo doping amount allows for the creation of ceramic-based composites with resistivities ranging from 10 to 10^12 Ω·cm. Furthermore, because Al2O3 ceramics exhibit excellent thermal shock resistance, corrosion resistance, and mechanical properties, Al2O3/Mo composites can find widespread applications as materials for high-power resistor components.