In today’s high-power density applications, efficient heat dissipation is a critical factor for ensuring the reliability and performance of electrical systems. Traditional air-cooled or indirect liquid-cooled resistors often struggle to meet the demands of modern industrial and energy systems. This is where immersed liquid-cooled resistors, particularly those utilizing advanced MAX phase ceramic, come into play. These cutting-edge devices are designed to deliver unparalleled thermal performance while maintaining long-term stability and reliability.

What is an Immersed Liquid-Cooled Resistor?

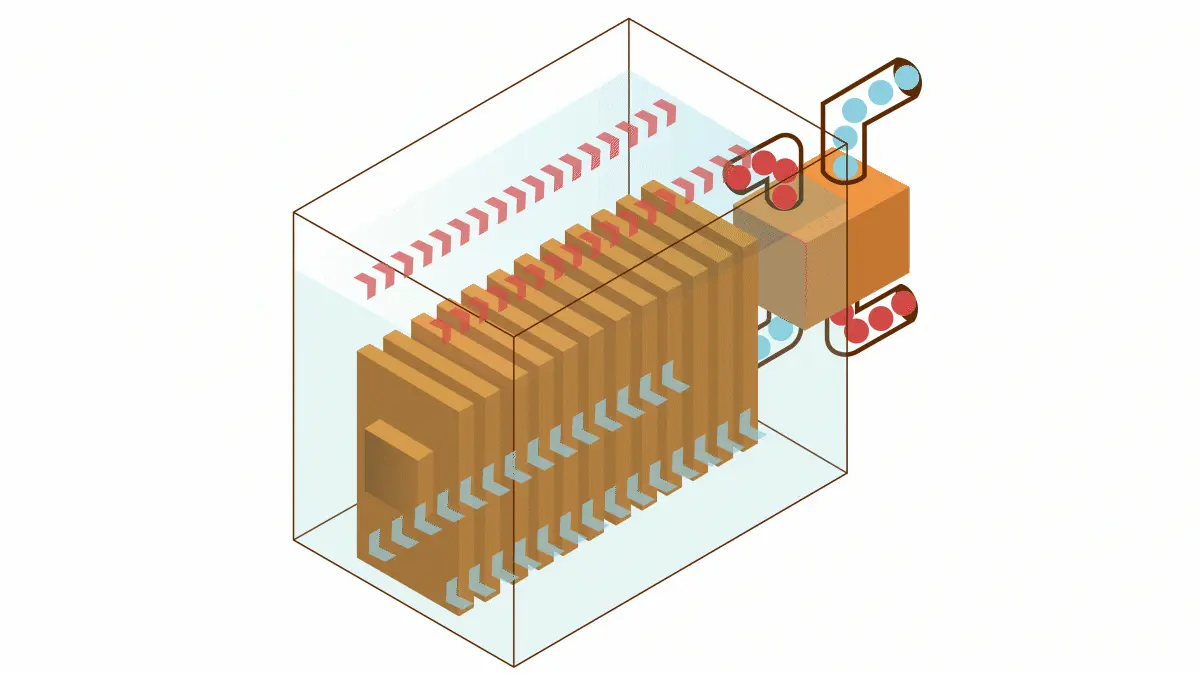

An immersed liquid-cooled resistor is a revolutionary device that directly submerges the resistor element in a non-conductive cooling fluid. Unlike traditional air-cooled or indirect liquid-cooled systems, this design allows heat to be transferred directly from the resistor to the cooling liquid, significantly improving thermal efficiency. This makes immersed liquid-cooled resistors ideal for applications requiring high power dissipation in compact spaces.

The MAX phase ceramic composite used in these resistors further enhances their performance. MAX phase ceramics are renowned for their unique combination of metallic and ceramic properties, including excellent thermal conductivity, mechanical strength, and resistance to environmental factors. Importantly, MAX phase ceramics are non-hygroscopic (do not absorb water), ensuring consistent performance even in humid environments.

Key Advantages of Immersed Liquid-Cooled Resistors

1. Superior Heat Dissipation By immersing the resistor in a non-conductive cooling liquid, heat is efficiently removed from the source. This direct cooling method ensures that the resistor operates at optimal temperatures, even under high-power loads. Compared to air-cooled systems, immersed liquid-cooled resistors can handle significantly higher power densities without compromising performance.

2. Compact Design The high thermal efficiency of liquid cooling allows for a more compact design. This is particularly beneficial in applications where space is limited, such as data centers, electric vehicles, and industrial automation systems.

3. Low Noise Operation Traditional air-cooled resistors rely on fans to dissipate heat, which can generate significant noise. Immersed liquid-cooled resistors eliminate the need for fans, resulting in quieter operation, making them suitable for noise-sensitive environments like laboratories and hospitals.

4. Durability and Reliability The use of MAX phase ceramic ensures exceptional durability. These materials are resistant to corrosion, oxidation, and mechanical stress, extending the lifespan of the resistor. Additionally, the non-hygroscopic nature of MAX phase ceramics ensures consistent performance in challenging environments.

5. Energy Efficiency By reducing the energy required for cooling, immersed liquid-cooled resistors contribute to overall system energy savings. This aligns with the growing demand for sustainable and energy-efficient solutions in modern industries.

Applications of Immersed Liquid-Cooled Resistors

The versatility of immersed liquid-cooled resistors makes them suitable for a wide range of applications:

Dynamic Braking Systems: In elevators, cranes, and electric vehicles, these resistors efficiently dissipate regenerative energy generated during braking. Renewable Energy Systems: Wind turbines and solar inverters benefit from the high power density and reliability of immersed liquid-cooled resistors. Data Centers: Ensuring stable operation of UPS systems and other critical infrastructure by managing excess energy efficiently. Industrial Automation: Providing reliable braking and load testing solutions for motor drives and manufacturing equipment. Laboratory Testing: Offering precise and consistent performance in high-power load simulation and testing environments.

Why Choose MAX Phase Ceramic for Liquid-Cooled Resistors?

The integration of MAX phase ceramic into immersed liquid-cooled resistors offers several unique advantages:

Thermal Conductivity: MAX phase ceramics exhibit excellent thermal properties, allowing for efficient heat transfer. Mechanical Strength: These materials are highly durable and can withstand extreme operating conditions. Chemical Stability: Non-reactive with cooling fluids, MAX phase ceramics ensure long-term compatibility and performance. Non-Hygroscopic Properties: Unlike some traditional materials, MAX phase ceramics do not absorb moisture, making them ideal for use in humid or wet environments.

Conclusion

As industries continue to demand higher power densities and more efficient thermal management solutions, immersed liquid-cooled resistors with MAX phase ceramic are poised to become the gold standard. Their ability to deliver superior heat dissipation, compact design, and long-term reliability makes them an invaluable asset in modern electrical systems.

Whether you’re designing dynamic braking systems, renewable energy solutions, or high-performance data centers, immersed liquid-cooled resistors offer the performance and efficiency needed to meet your goals. Embrace the future of thermal management with this innovative technology and experience the benefits of liquid-cooled resistors firsthand.