In the world of high-voltage and high-power electronics, reliability, precision, and durability are non-negotiable. Among the most critical components enabling safe and efficient operation in such environments are thick film power resistors. Engineered for performance under extreme conditions, these resistors have become indispensable in modern power systems—especially in the electrical and energy sectors. This article explores the key features and main applications of thick film power resistors, highlighting why they are the preferred choice for engineers and system designers worldwide.

What Are Thick Film Power Resistors?

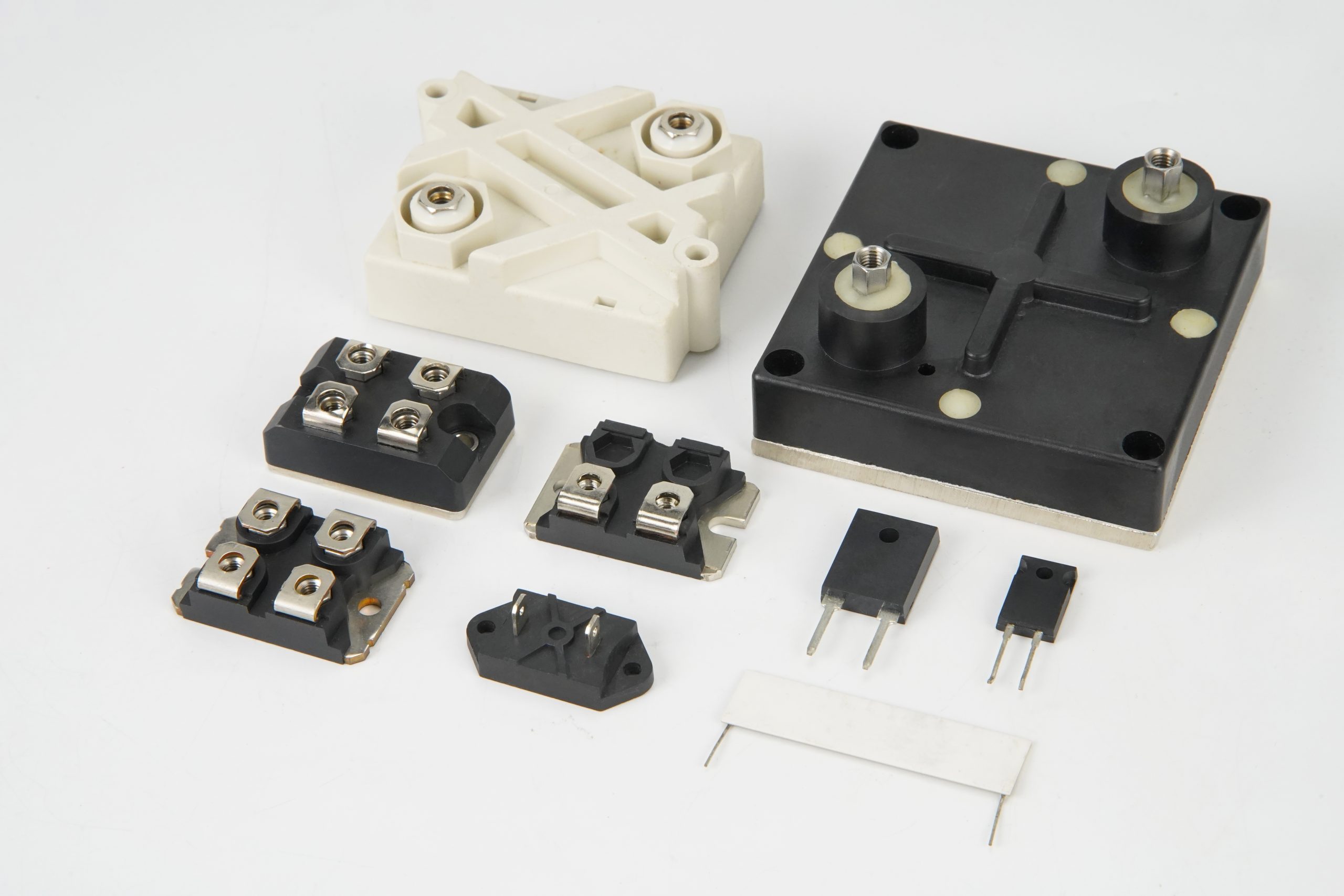

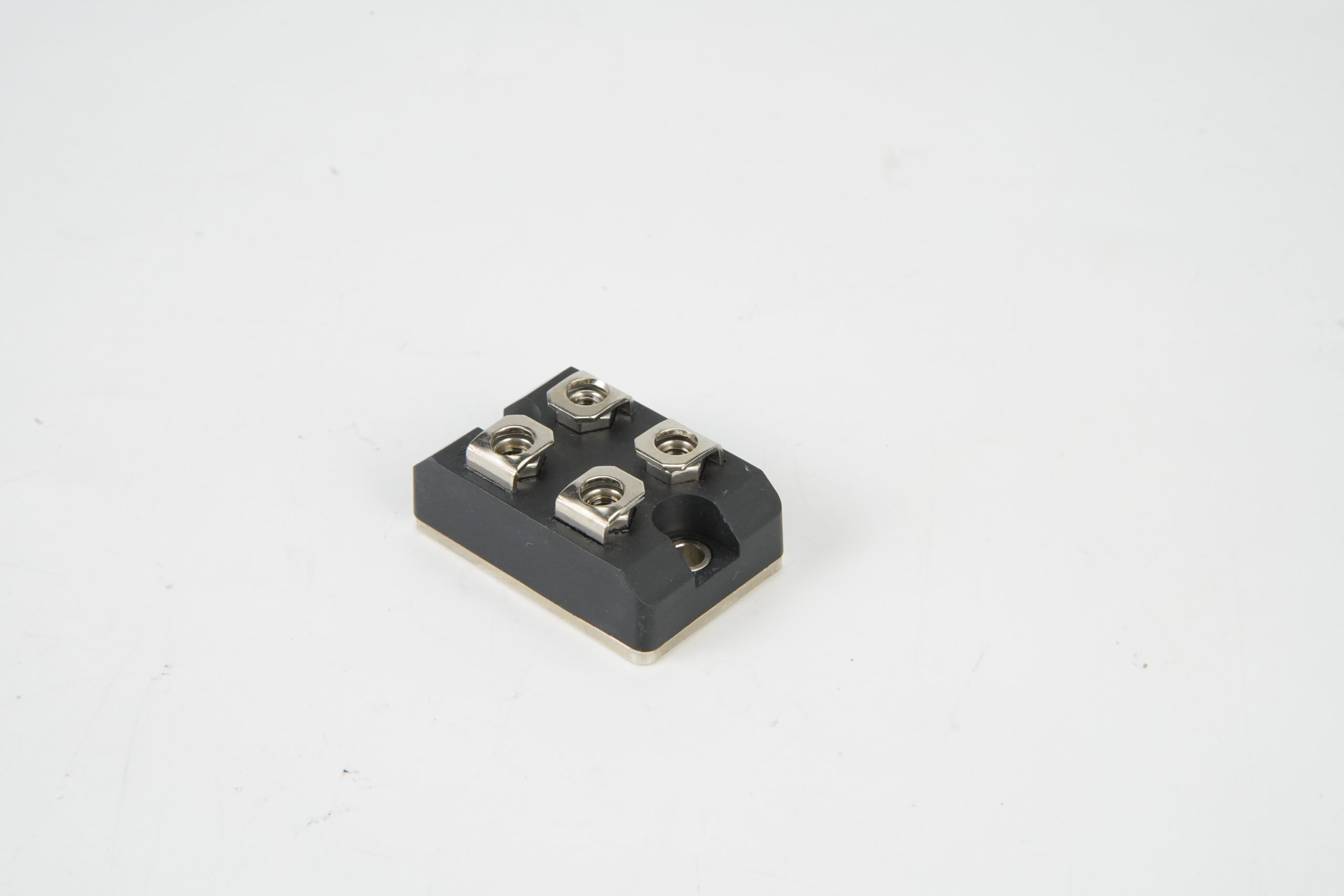

Thick film power resistors are robust passive components fabricated by screen-printing a conductive ceramic-metal (cermet) paste onto a high-thermal-conductivity ceramic substrate, typically aluminum oxide (Al₂O₃). This manufacturing technique allows for excellent heat dissipation, high voltage tolerance, and stable electrical performance over time—making them ideal for industrial and utility-scale applications.

The advanced thick film technology enables these resistors to support power ratings from 250W up to 2000W, with an exceptionally wide resistance range from 0.1 Ω to 100 MΩ. This versatility ensures they can be tailored to diverse circuit requirements, from low-ohmic current sensing to high-impedance voltage division.

Key Technical Advantages

Beyond their broad operational range, thick film power resistors offer several performance-enhancing characteristics:

- Ultra-low parasitic inductance (<40 nH): Critical for high-frequency and fast-switching applications, minimizing unwanted voltage spikes and electromagnetic interference (EMI).

- High insulation withstand voltage (12 kVrms): Ensures safety and reliability in high-voltage environments, preventing arcing or breakdown.

- Low partial discharge (<10 pC at 8 kVrms): Extends service life and maintains integrity in insulation systems, especially important in high-altitude or humid conditions.

These attributes make thick film power resistors uniquely suited for mission-critical roles in power transmission, renewable energy systems, and industrial automation.

Main Applications of Thick Film Power Resistors in the Power Sector

- Voltage Balancing (Grading) Resistors In high-voltage systems such as circuit breakers, switchgear, and HVDC (High-Voltage Direct Current) converters, voltage distribution across series-connected components must be uniform. Thick film power resistors act as grading or equalizing resistors, ensuring balanced voltage sharing and preventing localized overvoltage that could damage insulation or trigger failures.

- Discharge Resistors Energy storage systems—like capacitors in power electronics or DC link circuits—retain dangerous charges even after power is disconnected. Discharge resistors safely dissipate this stored energy, protecting maintenance personnel and downstream components. Thanks to their high power handling and thermal stability, thick film resistors provide rapid, reliable, and repeatable discharge performance.

- Filter Resistors in EMI/RFI Suppression In power conversion systems (e.g., inverters, rectifiers, and motor drives), unwanted harmonics and noise can degrade performance and interfere with nearby electronics. Thick film power resistors are integral to LC or RC filter networks, damping oscillations and smoothing current/voltage waveforms. Their low inductance ensures effective filtering even at high frequencies.

- Energy Harvesting (Pickup) Resistors In high-voltage monitoring systems—such as those used in smart grids or substation instrumentation—pickup or take-off resistors extract a small, proportional amount of energy from the main line to power sensors or communication modules. Thick film resistors offer the precision and long-term stability needed for accurate energy sampling without compromising system safety.

Why Choose Thick Film Technology?

Compared to wirewound or thin film alternatives, thick film power resistors strike an optimal balance between cost, performance, and scalability. They are non-inductive by design, resistant to thermal shock, and exhibit minimal drift over time—even under continuous high-power operation. Additionally, their compact form factor and customizable mounting options (e.g., flange or chassis mount) simplify integration into space-constrained enclosures.

Conclusion

As global demand for efficient, resilient, and intelligent power infrastructure grows, thick film power resistors continue to play a vital role in ensuring system safety, stability, and performance. Whether used for voltage grading, energy discharge, filtering, or power extraction, these components deliver unmatched reliability in the most demanding electrical environments. For engineers designing next-generation power systems—from renewable energy plants to electric vehicle charging stations—specifying high-quality thick film power resistors is a strategic investment in long-term operational excellence.

Explore our range of thick film power resistors today and discover how advanced passive components can elevate your power electronics design.