In demanding electrical and electronic systems—ranging from industrial power supplies to RF transmitters and capacitor discharge units—standard resistors often fall short. What engineers truly need are high-power, non-inductive resistors capable of handling extreme energy pulses, operating reliably at high frequencies, and maintaining stable performance under thermal stress. Fortunately, advanced ceramic-based resistor technologies now deliver exactly that.

Why Low Inductance Matters

Inductance in resistors can distort signals, limit response time, and cause voltage spikes in fast-switching or high-frequency circuits. For applications like antenna dummy loads, capacitor bank discharge, or neutral grounding in transformers, even microhenries of parasitic inductance can compromise system integrity. The ideal solution? Resistors engineered with bulk-conductive ceramic bodies that eliminate coiled or spiral structures entirely—achieving self-inductance as low as 10⁻⁷ henry.

Built for Extreme Energy Absorption

These resistors are fabricated from high-density ceramic composites (typically silico-aluminates with conductive carbon), sintered at elevated temperatures. This monolithic construction grants them exceptional thermal mass and mechanical robustness. As a result, they can absorb massive amounts of energy in short bursts—up to 250 joules per cubic centimeter for a 1-second pulse—without degradation.

For repetitive pulse applications, designers can refer to standardized energy ratings based on discharge duration (e.g., 0.01s, 0.1s, 1s, 10s) and cooling conditions. This makes them ideal for electrostatic precipitators, overvoltage protection circuits, and high-voltage test equipment.

High-Frequency Performance Up to 10 GHz

Thanks to their non-spiral, uniform conductive path, these resistors exhibit minimal impedance variation even at very high frequencies. While performance remains stable up to 25 MHz across all types, optimized geometries can extend reliable operation to 100 MHz or beyond. Specialized variants—featuring carbon-deposited rods with silver-plated terminations—are rated for use up to 10,000 MHz (10 GHz), making them perfect for VHF/UHF transmitters, RF dummy loads, and microwave test benches.

Their voltage coefficient is exceptionally low (as little as –0.001% per volt), ensuring consistent resistance under high electric fields.

Flexible Power Handling with Active Cooling

In free air at 25°C, surface temperatures are typically limited to 150–220°C, depending on resistance value. But power dissipation can be dramatically enhanced through forced cooling:

- Still water: 10× power increase

- Flowing water (10 cm/s): up to 40× the air-cooled rating

- Oil immersion: 3.5–10× improvement

For example, a resistor rated at 20W in air can safely dissipate over 800W in fast-flowing distilled water—provided it uses non-varnished bodies and silver metallization to prevent corrosion and electrolysis.

⚠️ Note: When using liquid cooling, always employ high-purity deionized water and protective glass enclosures to avoid electrochemical degradation.

Wide Resistance Range & Standard Values

Available resistance values span from 0.01 Ω (for disc/ring types) to 100 kΩ (for tubular forms), with standard tolerances of ±5%, ±10%, or ±20%. Engineers are encouraged to select values from the E12 or E6 IEC standard series for optimal availability and compatibility.

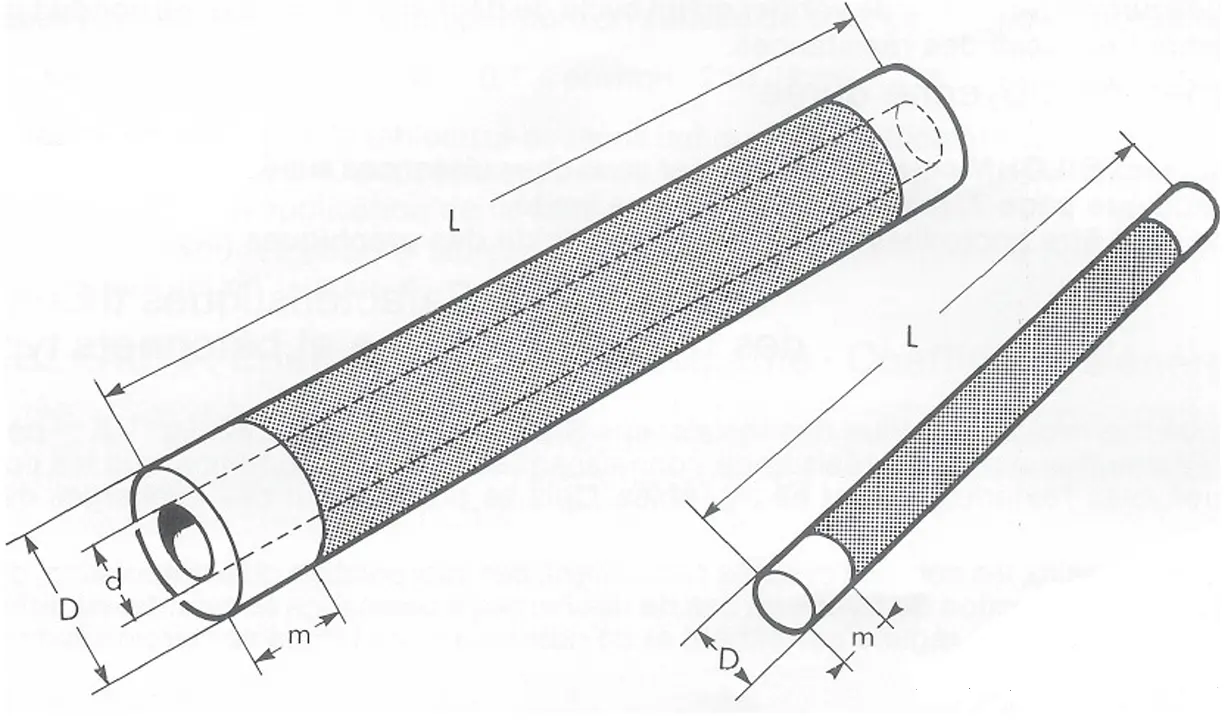

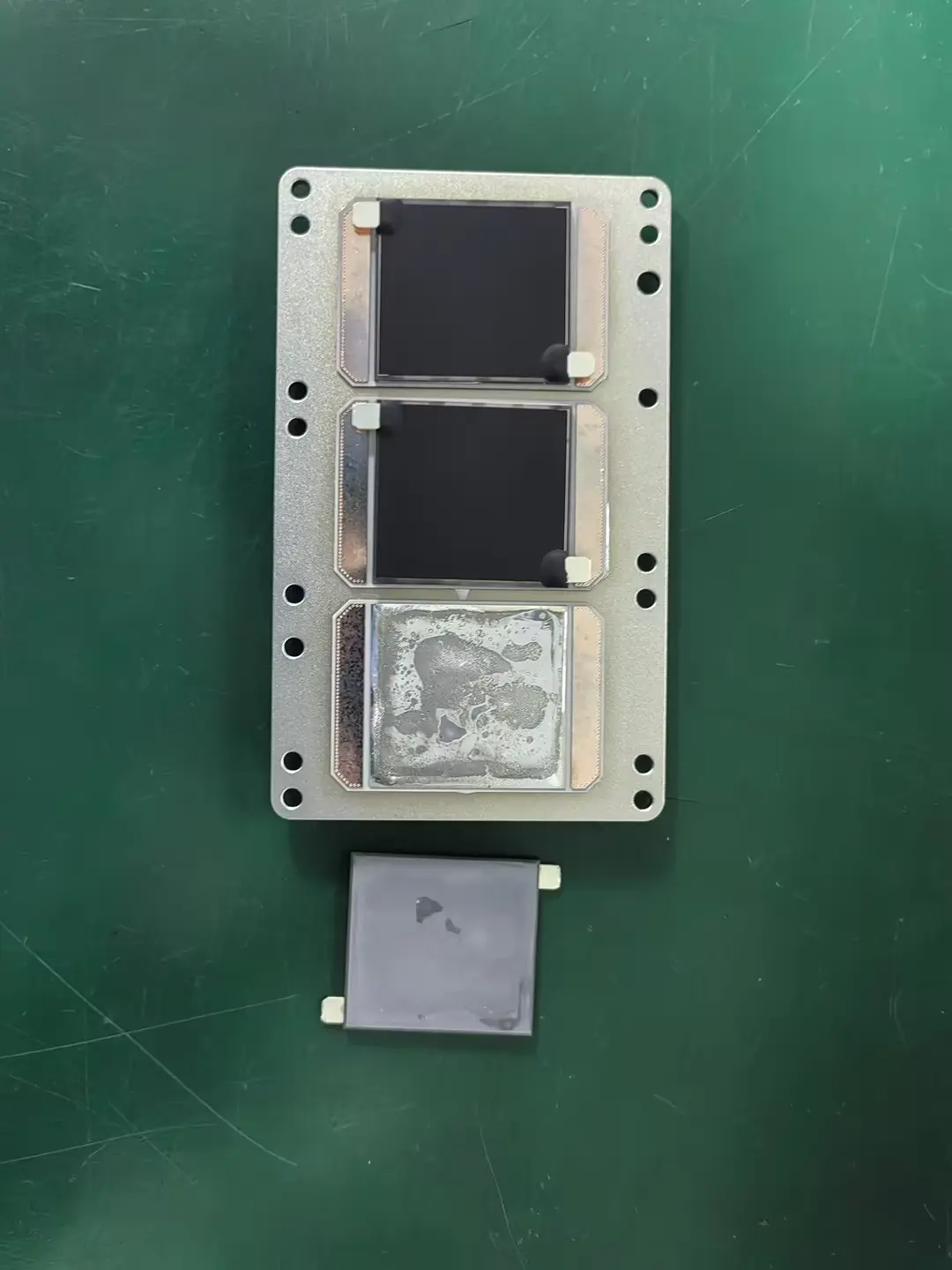

Physical formats include:

- Tubes and rods (for medium to high resistance)

- Discs and rings (for ultra-low resistance, high-current paths)

- Custom shapes for specialized mounting or thermal integration

Typical Applications

These non-inductive power resistors are trusted in critical roles such as:

- Capacitor bank discharge resistors

- RF dummy loads for antenna testing

- Neutral grounding in generators and transformers

- Damping resistors in snubber circuits

- High-frequency generator loads

- Voltage dividers in high-voltage systems

Design Considerations

When selecting a resistor, consider:

- Current type: DC, AC, or pulsed

- Frequency range

- Continuous vs. transient power requirements

- Cooling method (air, oil, water)

- Voltage gradient (max ~1.2 kV/cm in air)

- Thermal recovery time between pulses

Series or parallel configurations can be used to tailor total resistance and power handling to exact system needs.

Conclusion

For engineers tackling high-energy, high-frequency, or precision pulse applications, modern ceramic non-inductive resistors offer unmatched performance, reliability, and design flexibility. By leveraging their ultra-low inductance, high thermal capacity, and scalable cooling options, you can build safer, more efficient, and more robust electrical systems—whether in industrial, telecom, or power infrastructure environments.

Looking for the right resistor for your next high-power design? Focus on material composition, cooling strategy, and pulse energy ratings—not just ohmic value. The right choice could be the difference between system failure and flawless operation.