In the world of advanced materials, conductive ceramics like reaction-bonded silicon carbide (SiSiC) have emerged as a game-changer for high-performance electrical components. With over 82% silicon carbide content, a resistivity of 100 Ω·cm, and an impressive thermal conductivity of 160 W/m·K, SiSiC is ideal for producing high-power load resistors and high-frequency resistors . This article explores the design considerations, geometric structures, and diverse applications of SiSiC-based resistors, highlighting their advantages in modern industries.

Why Choose Reaction-Bonded Silicon Carbide (SiSiC)?

Reaction-bonded silicon carbide stands out due to its unique combination of properties:

- High Resistivity Control : With a resistivity of 100 Ω·cm, SiSiC can be tailored to meet specific resistance requirements for various applications.

- Exceptional Thermal Conductivity : At 160 W/m·K, SiSiC efficiently dissipates heat, making it perfect for high-power load resistors that generate significant thermal energy.

- Mechanical Strength and Durability : The material’s hardness and wear resistance ensure long-term reliability, even in harsh environments.

- High-Temperature Stability : SiSiC maintains its performance at extreme temperatures, making it suitable for aerospace, industrial furnaces, and other demanding applications.

These properties make SiSiC an excellent choice for manufacturing high-power load resistors and high-frequency resistors , where precision, durability, and thermal management are critical.

Designing Geometric Structures for Optimal Performance

To harness the full potential of SiSiC in resistor production, engineers must carefully design the geometric structure of the resistive elements. Here are some key considerations:

1. Length-to-Cross-Section Ratio

The resistance of a material is governed by the formula:

R=ρ⋅AL

Where R is resistance, ρ is resistivity (100 Ω·cm), L is length, and A is cross-sectional area. By increasing the length or reducing the cross-sectional area, manufacturers can achieve higher resistance values without compromising the material’s integrity.

2. Complex Shapes for Compact Designs

For space-constrained applications, complex geometries such as spiral or meandering paths can be used to increase the effective length of the resistive element while maintaining a compact footprint. This approach is particularly useful in high-frequency resistors , where minimizing parasitic inductance and capacitance is essential.

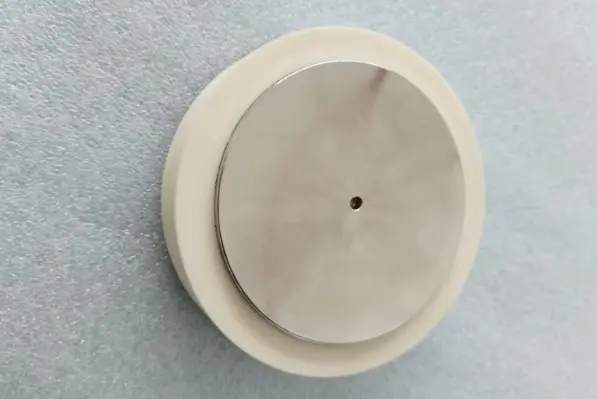

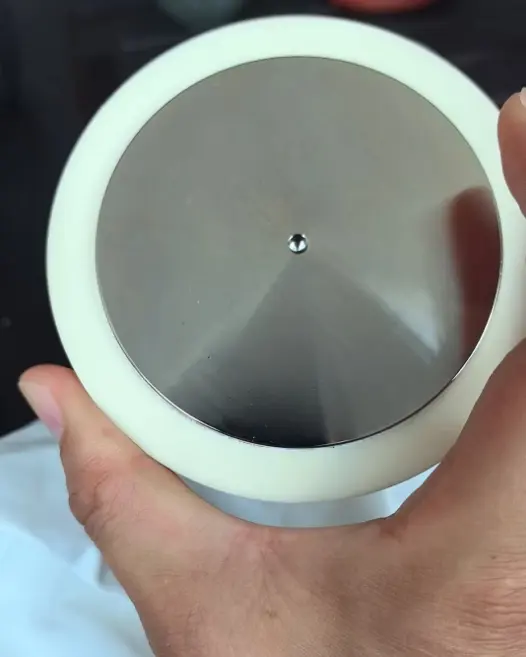

3. Surface Treatments and Electrode Connections

To enhance electrical contact and reduce oxidation, surface treatments such as metallization (e.g., nickel or silver plating) can be applied. Additionally, robust electrode connections using highly conductive materials like copper or silver paste ensure minimal contact resistance, improving overall efficiency.

4. Heat Dissipation Enhancements

Efficient heat dissipation is crucial for high-power load resistors. Incorporating features such as fins or integrating the resistor with a high-thermal-conductivity substrate (e.g., aluminum nitride or copper) can significantly improve cooling performance. Surface coatings with high emissivity further enhance radiative heat transfer.

Applications of SiSiC-Based Resistors

SiSiC resistors find applications across a wide range of industries due to their versatility and reliability:

1. High-Power Load Resistors

High-power load resistors are commonly used in power systems for energy dissipation during testing or fault conditions. SiSiC’s ability to withstand high currents and temperatures makes it an ideal material for these applications. Examples include:

- Power Grid Testing : Simulating loads in electrical grids to ensure stability and safety.

- Industrial Machinery : Managing excess energy in motors and generators.

2. High-Frequency Resistors

In RF (radio frequency) circuits, precise impedance matching and low parasitic effects are vital. SiSiC’s high-frequency performance and customizable resistance values make it a top choice for:

- Telecommunications : Ensuring signal integrity in wireless communication systems.

- Medical Devices : Supporting accurate operation in MRI machines and other diagnostic equipment.

3. Aerospace and Defense

SiSiC resistors excel in aerospace applications, where lightweight, durable components capable of operating under extreme conditions are required. These resistors are used in:

- Satellite Systems : Providing stable resistance in space environments.

- Military Electronics : Offering reliable performance in rugged conditions.

4. Industrial Furnaces and High-Temperature Environments

SiSiC’s thermal stability and corrosion resistance make it indispensable in high-temperature settings. Applications include:

- Heating Elements : Efficiently converting electrical energy into heat.

- Chemical Processing : Resisting aggressive chemicals while maintaining consistent electrical properties.

Conclusion

Reaction-bonded silicon carbide (SiSiC) represents a breakthrough in the development of high-power load resistors and high-frequency resistors . Its unique combination of high resistivity, exceptional thermal conductivity, and mechanical strength ensures superior performance in demanding applications. By carefully designing geometric structures and incorporating advanced heat dissipation techniques, manufacturers can unlock the full potential of SiSiC in modern electronics.

Whether you’re working on telecommunications infrastructure, aerospace technology, or industrial machinery, SiSiC-based resistors offer unparalleled reliability and efficiency. Explore the possibilities of this advanced material and elevate your projects to new heights today!