In demanding industrial, transportation, and energy applications, managing high-power dissipation efficiently and safely is non-negotiable. Enter the next-generation 30–40 kW liquid-cooled resistor module—engineered for extreme reliability, ultra-low thermal resistance, and scalable power handling through intelligent series-parallel thick-film resistor design.

Why Liquid Cooling for 30–40 kW Applications?

At power levels exceeding 30 kW, air cooling becomes impractical due to size, noise, and thermal limitations. Liquid-cooled resistor modules solve this by integrating direct fluid contact with high-conductivity substrates, enabling compact, silent, and highly efficient energy dissipation—ideal for electric vehicle test benches, regenerative braking systems, grid simulators, and industrial motor drives.

Core Innovations: From Substrate to System

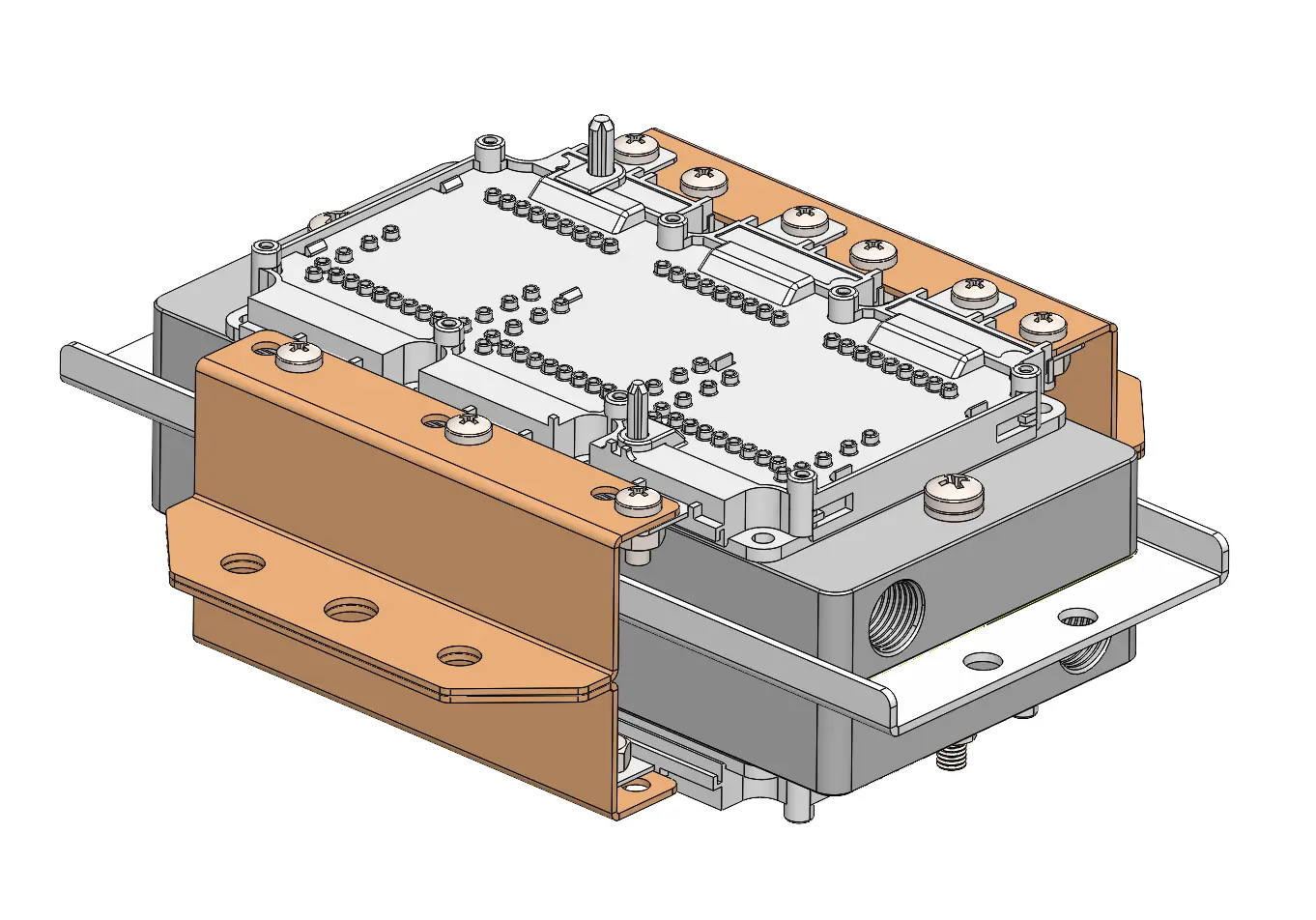

Our 30–40 kW modules are built on a multi-layer advanced architecture:

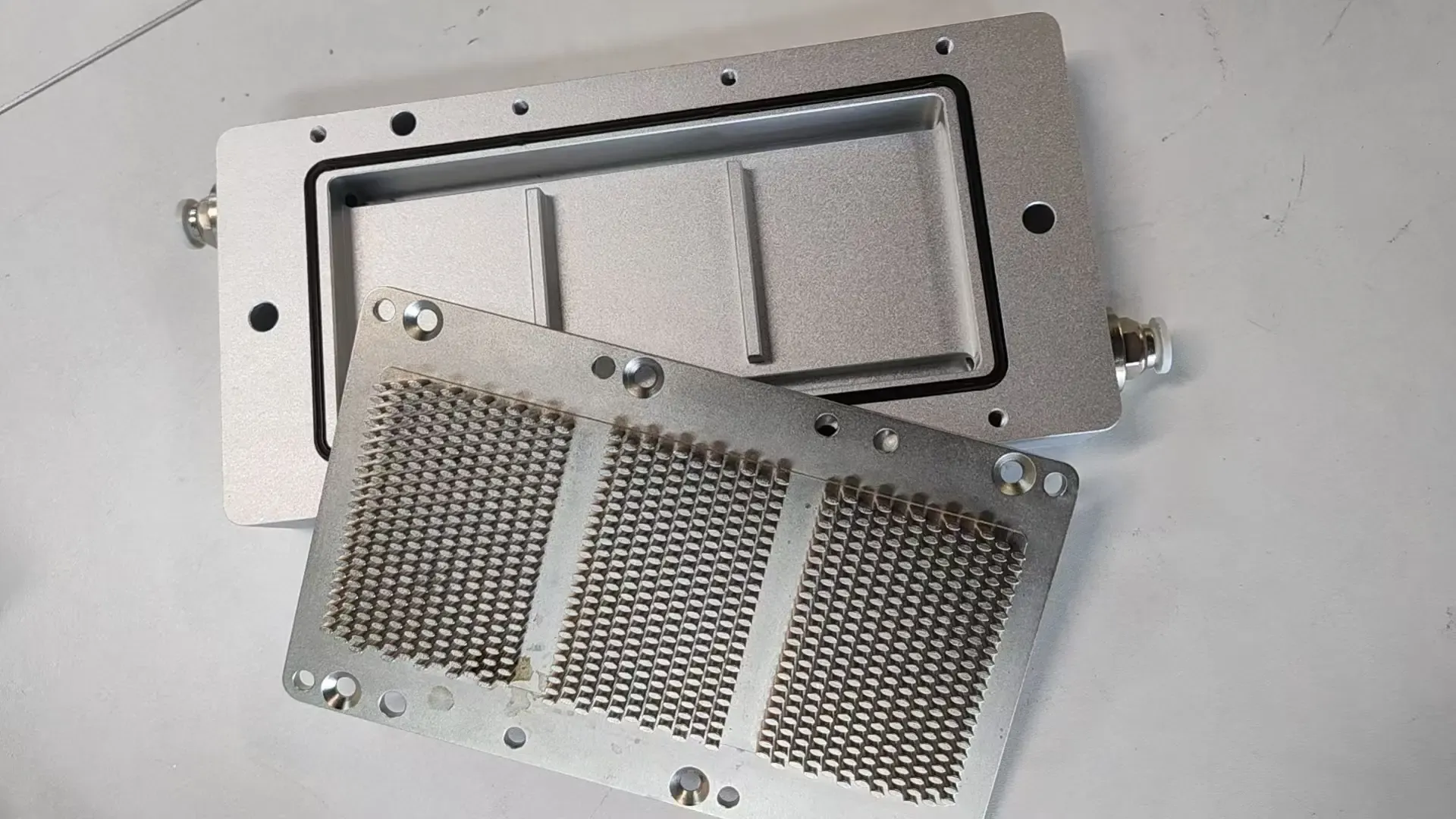

- PinFin Copper Baseplate: Precision-machined with dense pin-fin arrays to maximize surface area in contact with coolant. This design achieves 2–3× higher heat transfer efficiency compared to flat-channel coolers.

- Diamond-Reinforced AMB Substrate: Instead of conventional AlN or BeO, we use active metal brazed (AMB) ceramic substrates enhanced with synthetic diamond particles. With thermal conductivity exceeding 600 W/m·K, this substrate spreads heat instantly, minimizing hot spots and enabling stable operation under continuous high load.

- Thick-Film Resistor Network: High-stability ruthenium-based thick-film resistors are laser-trimmed and arranged in custom series-parallel configurations. This allows precise resistance values (e.g., 0.5 Ω to 50 Ω) while distributing current evenly—critical for balancing power across the module and preventing localized overheating.

- Robust Electrical Interfaces: Heavy-duty copper busbars with silver plating ensure minimal contact resistance and support currents up to 1,000 A, compatible with standard industrial connectors.

Scalable & Modular by Design

Need more than 40 kW? Multiple modules can be easily paralleled to scale power capacity while maintaining thermal uniformity. Each unit operates independently with its own cooling loop or can be integrated into a centralized liquid cooling system using quick-connect fittings. The modular approach reduces downtime, simplifies maintenance, and supports future upgrades.

Real-World Performance

In a recent rail traction application, two 35 kW modules were deployed in a back-to-back configuration for bidirectional braking energy absorption. Thanks to the diamond-AMB substrate and optimized PinFin cooling, the system maintained a junction-to-fluid thermal resistance below 0.02 K/W, even during 10-minute continuous duty cycles at full load.

Compliance & Reliability

All modules undergo rigorous testing for:

- Dielectric strength (>5 kV AC)

- Thermal cycling (-40°C to +125°C)

- Vibration and shock resistance (per IEC 60068)

- Coolant compatibility (deionized water, glycol mixtures)

Conclusion: Power Density Meets Precision

For engineers designing high-power electronic loads, braking systems, or dynamic test platforms, the 30–40 kW liquid-cooled resistor module represents the pinnacle of thermal and electrical integration. By combining diamond-enhanced substrates, PinFin cooling, and intelligent thick-film resistor networking, it delivers unmatched performance in the smallest possible footprint.

Upgrade your power dissipation strategy—engineer with confidence, cool with precision.