In the rapidly evolving electric vehicle (EV) industry, ensuring battery safety and performance is paramount. A critical component in this process is the rigorous testing of Battery Management Systems (BMS), which monitor and control every aspect of a battery pack’s operation. As EV batteries grow larger and more powerful, traditional air-cooled test equipment is reaching its limits. This case study highlights how a leading automotive R&D center successfully implemented liquid-cooled resistors to overcome thermal challenges and achieve reliable, high-fidelity BMS validation.

Challenge: Thermal Runaway in High-Power Testing

The engineering team was tasked with validating a new 800V, 200kW BMS designed for fast-charging applications. Their existing test bench used an air-cooled electronic load to simulate battery discharge during charging scenarios. However, during sustained 150kW tests, the load’s temperature soared within minutes, triggering automatic shutdowns due to overheating. This not only interrupted long-duration stress tests but also introduced measurement inaccuracies caused by thermal drift. The team needed a solution that could handle continuous high-power dissipation without compromising stability or data integrity.

Solution: Integrating Liquid-Cooled Resistor Technology

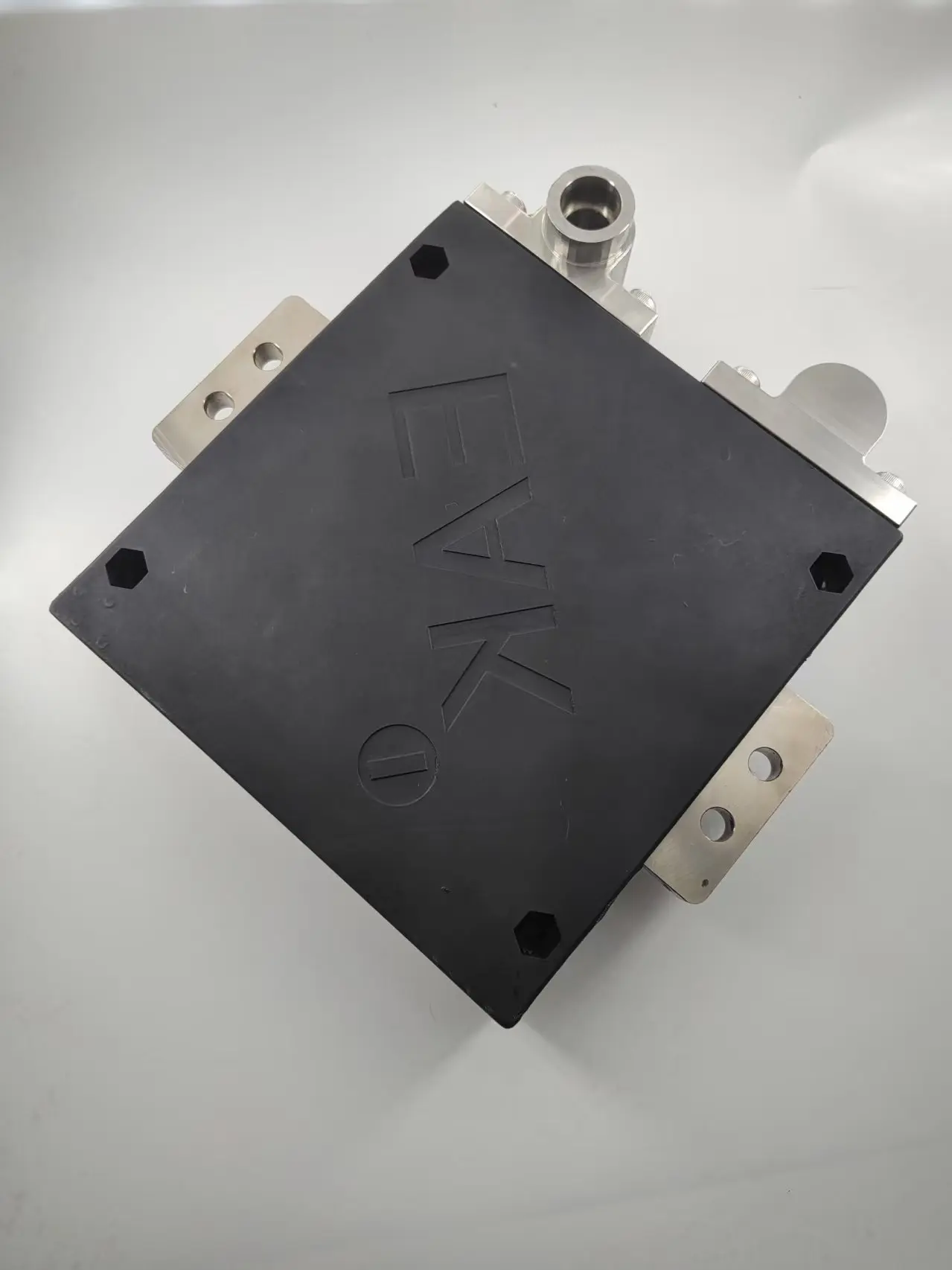

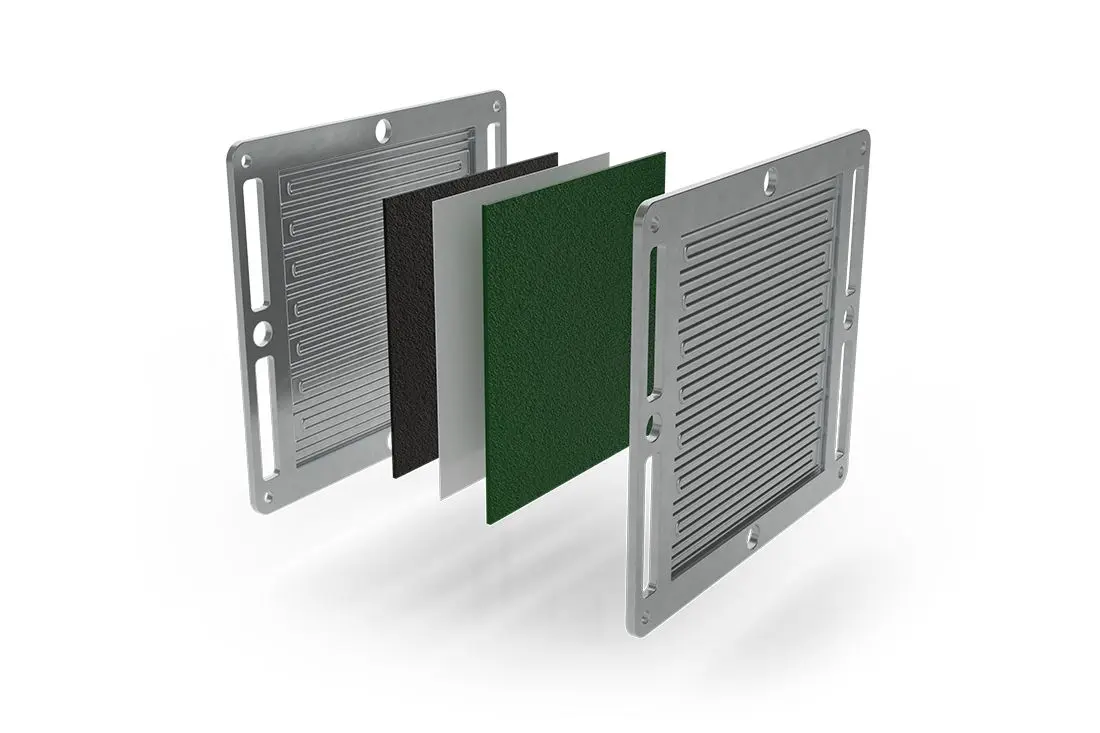

To address this, the lab upgraded to a next-generation bidirectional power supply system equipped with integrated liquid-cooled resistors. These resistors utilize a closed-loop cooling system where deionized water circulates directly through copper cold plates bonded to the high-power resistor elements. This design enables heat transfer efficiency up to 3–5 times greater than forced-air systems.

The new setup allowed the team to run full-load tests at 180kW continuously for over 6 hours without any thermal throttling. The stable operating temperature ensured consistent resistance values and precise current regulation, essential for evaluating the BMS’s overcurrent protection and state-of-charge (SOC) estimation algorithms under real-world conditions.

Enhanced Simulation Fidelity and System Reliability

Beyond thermal management, the liquid-cooled system supported advanced test scenarios. By pairing the high-power sink capability with programmable voltage profiles, engineers could accurately simulate complex charge-discharge cycles, including regenerative braking pulses and rapid DC fast-charging sequences. The fast transient response (<10µs) of the liquid-cooled load enabled realistic emulation of dynamic load changes, capturing subtle voltage sags and recovery behaviors critical for BMS calibration.

Moreover, the reduced acoustic noise and compact footprint improved the working environment, while the extended equipment lifespan lowered total cost of ownership. For high-channel-count testing, multiple units were synchronized, all sharing a central chiller unit for efficient plant-wide cooling.

Conclusion: A Standard for Future-Proof Testing

This application demonstrates that liquid-cooled resistors are no longer a niche option but a necessity for modern, high-power BMS verification. As battery systems push toward higher energy densities and faster charging, thermal management in test environments becomes as crucial as in the final product. By adopting liquid-cooled technology, engineering teams can ensure test continuity, measurement accuracy, and system reliability—key factors in accelerating innovation and bringing safer, more efficient electric vehicles to market.

For industries demanding extreme power and precision, liquid-cooled resistors have become the cornerstone of advanced battery testing infrastructure.