In the realm of high-energy electrical systems, reliability, thermal management, and precision are non-negotiable. Meet the carbon ceramic resistor—a cutting-edge passive component engineered for extreme conditions. Specifically, our megajoule-level water-cooled discharge resistor represents the pinnacle of performance, durability, and adaptability, making it ideal for defense, industrial, and pulsed power applications.

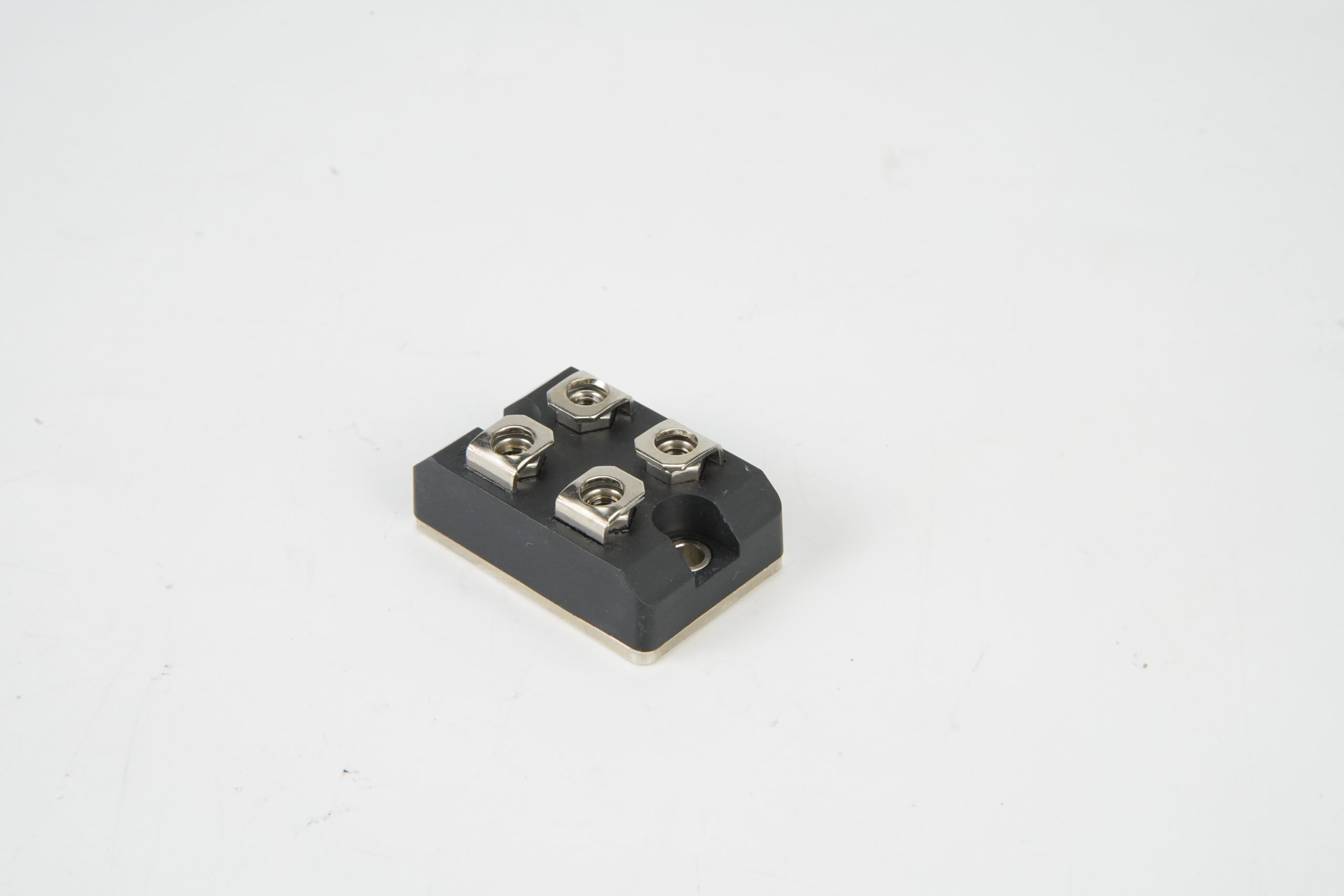

What Is a Carbon Ceramic Resistor? A carbon ceramic resistor is constructed using a composite of carbon-based conductive materials embedded within a high-purity ceramic matrix. This unique formulation delivers exceptional thermal stability, high energy absorption capacity, low inductance, and outstanding resistance to oxidation and mechanical shock. Unlike traditional wire-wound or metal oxide resistors, carbon ceramic resistors maintain stable performance even under repeated high-energy pulses—ranging from kilojoules (kJ) to megajoules (MJ).

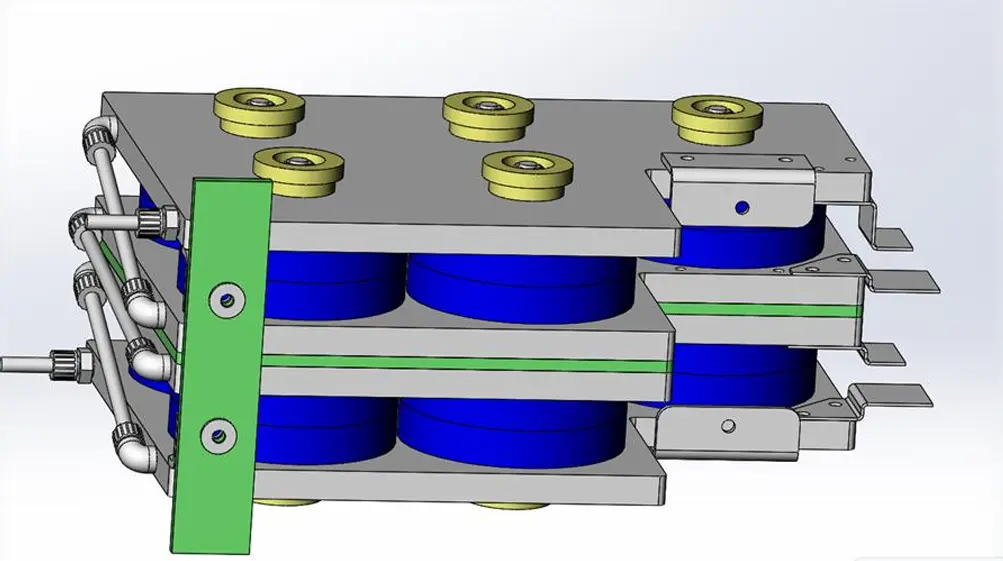

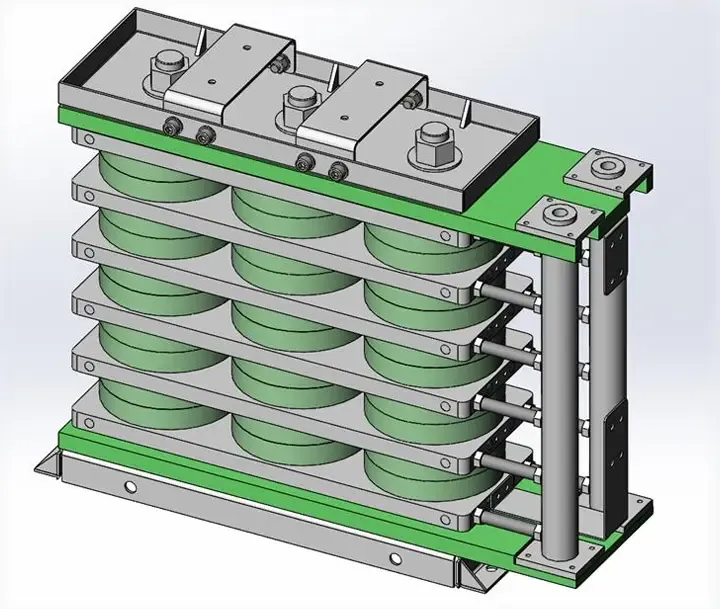

Megajoule-Level Water-Cooled Discharge Resistor: Engineered for Extreme Duty Our flagship product, the megajoule-level water-cooled discharge resistor, is purpose-built to safely dissipate massive amounts of energy in critical systems. Designed with integrated liquid cooling channels, this resistor efficiently transfers heat away from the ceramic core, enabling continuous or repetitive operation without thermal runaway or performance degradation.

Carbon Ceramic Resistors

Carbon Ceramic Resistors

Key features include:

- Energy Handling Capacity: Rated for 1 to 10+ megajoules, suitable for capacitor bank discharge, electromagnetic launch systems, and high-power test equipment.

- Advanced Water-Cooling Architecture: Direct-flow cooling paths ensure rapid heat dissipation, maintaining safe operating temperatures even during sustained high-power cycles.

- Modular & Scalable Design: Multiple resistor elements can be configured in series or parallel to meet exact voltage, current, and resistance requirements.

- Robust Construction: Hermetically sealed ceramic cores with corrosion-resistant metal housings ensure long service life in harsh environments.

Flexible Integration, Proven Reliability One of the standout advantages of our carbon ceramic resistors is their integration flexibility. Whether you need a compact single-unit module or a multi-stack array for higher power density, our design accommodates various mounting and cooling configurations—including forced air, natural convection, or liquid cooling. The water-cooled variant is particularly favored in applications where space is limited but thermal loads are extreme.

Military-Grade Performance, Globally Recognized This megajoule-level water-cooled discharge resistor has been mass-produced and deployed in active defense systems, having passed rigorous military environmental and performance standards. Independent expert evaluations confirm that its technical specifications—energy density, pulse stability, thermal response, and lifetime—rank among the best in the world, achieving international leading status.

Typical Applications

- Pulsed power systems (e.g., railguns, laser drivers)

- High-voltage capacitor bank discharge circuits

- Regenerative braking and energy absorption in industrial drives

- Grid fault current limiters and energy storage safety systems

- Aerospace and defense electronic countermeasures

Why Choose Our Carbon Ceramic Resistors? Backed by years of R&D and field validation, our carbon ceramic resistors combine material science innovation with practical engineering. The megajoule-level water-cooled discharge resistor isn’t just a component—it’s a mission-critical solution for engineers who demand zero compromise on safety, efficiency, and resilience.

For system integrators, defense contractors, and power electronics designers, this resistor offers a future-proof answer to today’s most challenging energy dissipation problems. With scalable architecture, proven military deployment, and superior thermal management, it sets a new benchmark in high-energy resistor technology.

Discover the power of precision. Trust the resilience of ceramic. Deploy the megajoule advantage.