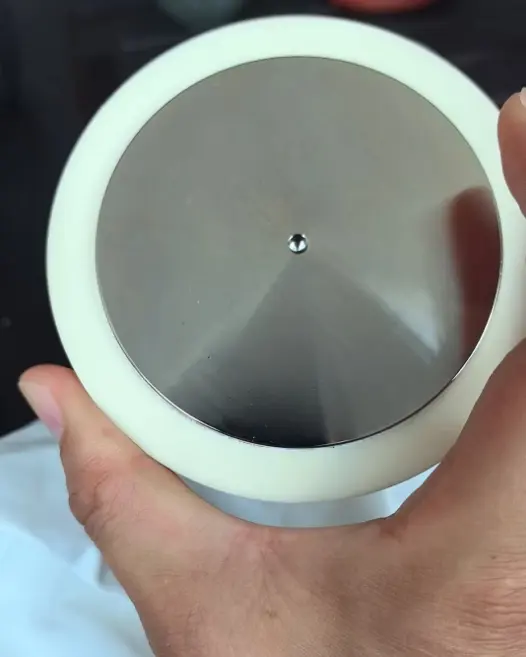

When it comes to high-performance resistors capable of withstanding extreme temperatures, mechanical stress, and electrical demands, alumina conductive ceramic resistors stand out as a reliable solution. Made from aluminum oxide (Al₂O₃), these resistors combine exceptional mechanical properties with excellent electrical performance, making them ideal for demanding applications in industries such as aerospace, automotive, and industrial manufacturing.

Why Choose Alumina Conductive Ceramic Resistors?

Alumina (Al₂O₃) is renowned for its remarkable physical and chemical properties. With a melting point of approximately 2050°C , alumina-based ceramics can operate at temperatures up to 1600°C , far exceeding the capabilities of traditional resistive materials. Additionally, alumina boasts a hardness of 9 on the Mohs scale , ensuring resistance to wear and tear even under harsh conditions. These characteristics make alumina an excellent choice for applications requiring both durability and reliability.

The conductivity of alumina ceramics can be tailored through doping with metals or carbon-based materials. This allows manufacturers to achieve specific electrical resistances while maintaining the material’s inherent mechanical strength. As a result, alumina conductive ceramic resistors are widely used in high-power applications where precision and stability are critical.

Key Features of Alumina Conductive Ceramic Resistors

- High Mechanical Strength and Hardness : The robust nature of alumina ensures that these resistors can withstand significant mechanical stress without cracking or deforming. This makes them suitable for environments prone to vibration or impact.

- Superior Temperature Resistance : Operating temperatures of up to 1600°C make these resistors ideal for use in furnaces, engine compartments, and other high-temperature settings. Unlike many conventional resistors, alumina ceramics remain stable and functional even when exposed to prolonged heat.

- Customizable Conductivity : By incorporating dopants like tungsten, molybdenum, or graphite, manufacturers can adjust the resistivity of alumina ceramics to meet specific application needs. Typical resistance values range from 1 ohm to several megaohms , with tolerances as tight as ±1% .

- High Power Handling Capability : Alumina conductive ceramic resistors are designed to handle power ratings from 50 watts to over 1000 watts , depending on size and configuration. For example, a standard resistor measuring 20mm x 10mm x 5mm can dissipate up to 200 watts continuously.

- Excellent Voltage Stability : These resistors support working voltages ranging from 100V to 10kV , ensuring consistent performance across a wide spectrum of electrical systems. Their low temperature coefficient of resistance (TCR) minimizes drift during operation, enhancing overall accuracy.

Applications Across Industries

The versatility of alumina conductive ceramic resistors makes them indispensable in numerous fields:

- Aerospace : Used in jet engines and satellite components due to their ability to function reliably in high-temperature environments.

- Automotive : Employed in braking systems and exhaust sensors, where thermal stability and durability are paramount.

- Industrial Manufacturing : Ideal for furnace heating elements and motor control circuits that require precise resistance values under heavy loads.

- Energy Sector : Utilized in power distribution systems and renewable energy installations for their high voltage and current handling capabilities.

For instance, in electric vehicle (EV) battery management systems, alumina resistors with a resistance value of 10 kΩ ±1% and a power rating of 200W ensure efficient energy dissipation while maintaining safety standards.

Technical Specifications at a Glance

- Material : Aluminum Oxide (Al₂O₃)

- Maximum Operating Temperature : Up to 1600°C

- Resistance Range : 1Ω – 1MΩ

- Power Rating : 50W – 1000W

- Tolerance : As low as ±1%

- Working Voltage : 100V – 10kV

- Hardness : 9 Mohs

Conclusion: The Future of Resistor Technology

As technology advances, the demand for components that can perform reliably under extreme conditions continues to grow. Alumina conductive ceramic resistors represent the cutting edge of resistor design, offering unparalleled durability, precision, and adaptability. Whether you need a resistor for high-power industrial machinery, space exploration equipment, or next-generation EVs, alumina ceramics provide the perfect balance of performance and longevity.

Investing in alumina conductive ceramic resistors not only ensures superior functionality but also future-proofs your systems against the challenges of tomorrow. If you’re looking for a resistor that combines strength, stability, and scalability, look no further than alumina conductive ceramic resistors —the ultimate solution for modern engineering challenges.