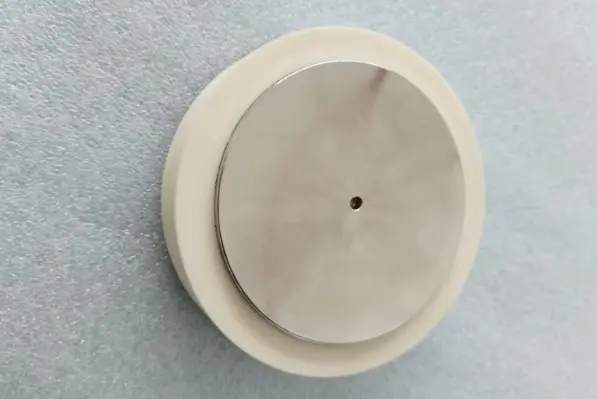

High-Power Ceramic Resistors

High-Power Ceramic Resistors

In the world of advanced electronics, the demand for high-performance resistors is growing rapidly. Whether it’s for high-frequency circuits, high-power applications, or energy absorption systems, engineers need materials that can deliver exceptional performance under extreme conditions. This is where Aluminum Nitride (AlN) conductive ceramics come into play. With their unmatched thermal conductivity, low thermal expansion coefficient, and customizable electrical properties, AlN-based resistors are revolutionizing industries such as aerospace, telecommunications, and power electronics.

Unmatched Thermal Conductivity for High-Power Applications

One of the standout features of aluminum nitride conductive ceramics is their exceptional thermal conductivity , which ranges from 170 to 220 W/m·K . This makes them one of the best-performing ceramic materials in terms of heat dissipation. For high-power ceramic resistors , efficient thermal management is critical to prevent overheating and ensure long-term reliability. Traditional materials like alumina (Al₂O₃) or zirconia (ZrO₂) simply cannot match the thermal performance of aluminum nitride.

In applications such as electric vehicles, industrial motor drives, and renewable energy systems, high-power density resistors are essential. These resistors must handle significant electrical loads while maintaining stable performance. Aluminum nitride’s superior thermal properties allow it to dissipate heat quickly, ensuring that these resistors operate safely even under heavy loads.

Low Thermal Expansion for Stability in Extreme Environments

Another key advantage of aluminum nitride is its low coefficient of thermal expansion (CTE) , which is approximately 4.5×10⁻⁶/°C . This property ensures minimal dimensional changes when exposed to temperature fluctuations, making aluminum nitride ideal for use in environments with wide temperature variations. For example, in high-frequency resistors used in aerospace or satellite communication systems, stability is crucial. The low CTE of aluminum nitride minimizes mechanical stress and prevents cracking or failure during thermal cycling.

The combination of high thermal conductivity and low thermal expansion also makes aluminum nitride an excellent choice for energy absorption resistors . These resistors are often used in surge protection devices and pulse power systems, where they must absorb large amounts of energy without degrading. The robustness of aluminum nitride ensures consistent performance in such demanding scenarios.

Customizable Electrical Properties Through Doping

While pure aluminum nitride is inherently an electrical insulator, its properties can be tailored through doping or composite design. By incorporating conductive phases such as titanium carbide (TiC), silicon carbide (SiC), or graphene, manufacturers can achieve a wide range of resistivity values—from 10⁻⁴ to 10³ Ω·cm . This versatility allows aluminum nitride to be used in both high-resistance and low-resistance applications, depending on the specific requirements of the circuit.

For instance, high-frequency resistors require materials with low dielectric loss and excellent signal integrity. Aluminum nitride’s naturally low dielectric constant (~8-9) and low loss tangent make it an ideal candidate for RF and microwave circuits. Similarly, high-power ceramic resistors benefit from the material’s ability to maintain stable resistance over time, even in harsh operating conditions.

Applications Across Industries

The unique combination of properties offered by aluminum nitride conductive ceramics makes them suitable for a variety of cutting-edge applications:

- High-Frequency Resistors : In telecommunications and radar systems, aluminum nitride resistors provide reliable performance at high frequencies due to their low dielectric loss and excellent thermal management.

- High-Power Ceramic Resistors : From electric vehicle inverters to industrial machinery, these resistors excel in managing high current densities and dissipating heat efficiently.

- Energy Absorption Resistors : In surge protectors and pulsed power systems, aluminum nitride’s durability and thermal stability ensure safe operation during transient events.

Why Choose Aluminum Nitride Conductive Ceramics?

When selecting materials for advanced resistors, engineers must consider factors such as thermal conductivity, electrical performance, and environmental resilience. Aluminum nitride conductive ceramics check all the boxes:

- Superior thermal management thanks to its high thermal conductivity.

- Mechanical strength and chemical resistance , ensuring longevity in harsh environments.

- Tailored electrical properties , enabling precise control over resistance and temperature coefficients.

Whether you’re designing high-frequency resistors , high-power ceramic resistors , or energy absorption resistors , aluminum nitride offers unparalleled advantages. Its ability to perform reliably under extreme conditions makes it a top choice for modern electronic systems.

Conclusion

As technology continues to advance, the need for high-performance resistors will only increase. Aluminum nitride conductive ceramics stand out as a material that meets the demands of today’s most challenging applications. With their incredible thermal conductivity, low thermal expansion, and customizable electrical properties, they are setting new standards for efficiency and reliability. If you’re looking to develop next-generation resistors for high-frequency, high-power, or energy-absorbing applications, aluminum nitride is undoubtedly the material of the future.