Engineered for extreme electrical environments, this 95mm-diameter pulse resistor delivers exceptional performance in high-voltage transient suppression, regenerative braking, and energy dissipation systems. Designed as both an energy absorption resistor and a robust surge resistor, it excels in applications demanding reliable handling of high-energy pulses, excellent insulation integrity, and stable resistance under thermal stress.

Engineered for High-Energy Pulse Demands

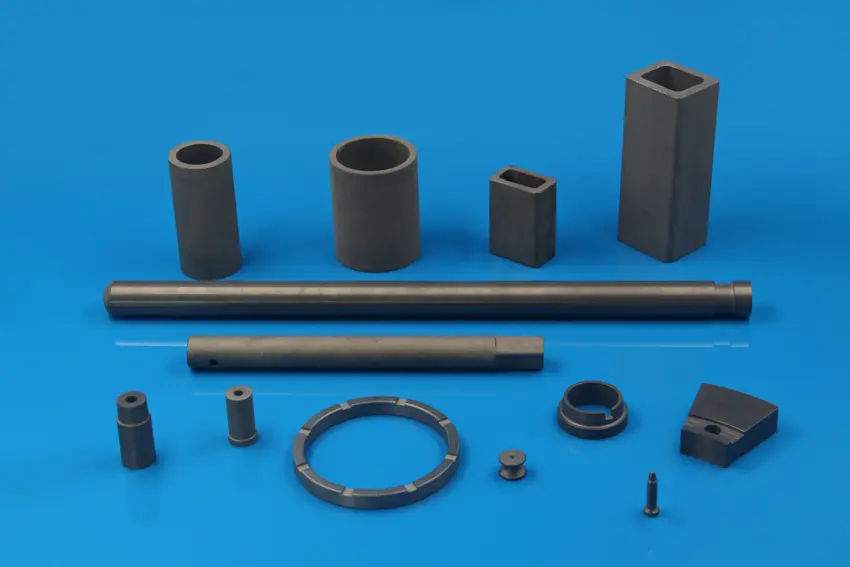

This ceramic-based pulse resistor features a nominal resistance of 3000 Ω (±10%) and can safely absorb single-pulse energies up to 105 kJ, making it ideal for use in braking circuits, capacitor discharge systems, and HVDC snubber networks. Its large physical dimensions (342 mm × 95 mm × 145 mm) provide ample thermal mass to manage short-duration overloads without degradation.

Unmatched Surge Withstand Capability

As a high-performance surge resistor, it withstands lightning impulse tests per the 1.2/50 μs waveform standard at 15 kV peak, applied twice, with post-test resistance drift limited to less than ±5%. This stability under repeated high-voltage transients ensures long-term reliability in power electronics, industrial drives, and renewable energy inverters exposed to grid surges or switching spikes.

Additionally, the unit meets a dielectric strength rating of ≥25 kV (1-second test) and maintains an insulation resistance of ≥2000 MΩ at DC 1000V, guaranteeing safe operation even in high-humidity or high-altitude installations (up to 2500 meters).

Thermal and Material Characteristics

Constructed from high-density ceramic (2.2–2.4 g/cm³), the resistor offers excellent mechanical strength and electrical insulation. However, due to its low thermal conductivity (1.22 W/m·K), it is not suited for continuous or high-frequency pulsing without external cooling. The design is optimized for intermittent duty cycles, with a maximum continuous operating temperature of 150°C and a short-term peak tolerance of 220°C.

Notably, the resistor exhibits a negative temperature coefficient of resistance (–0.08% to –0.03%/°C), meaning its resistance decreases slightly as temperature rises. This behavior must be accounted for in precision timing or feedback-controlled circuits but can be advantageous in self-regulating thermal protection schemes.

Application Flexibility with Proper Thermal Management

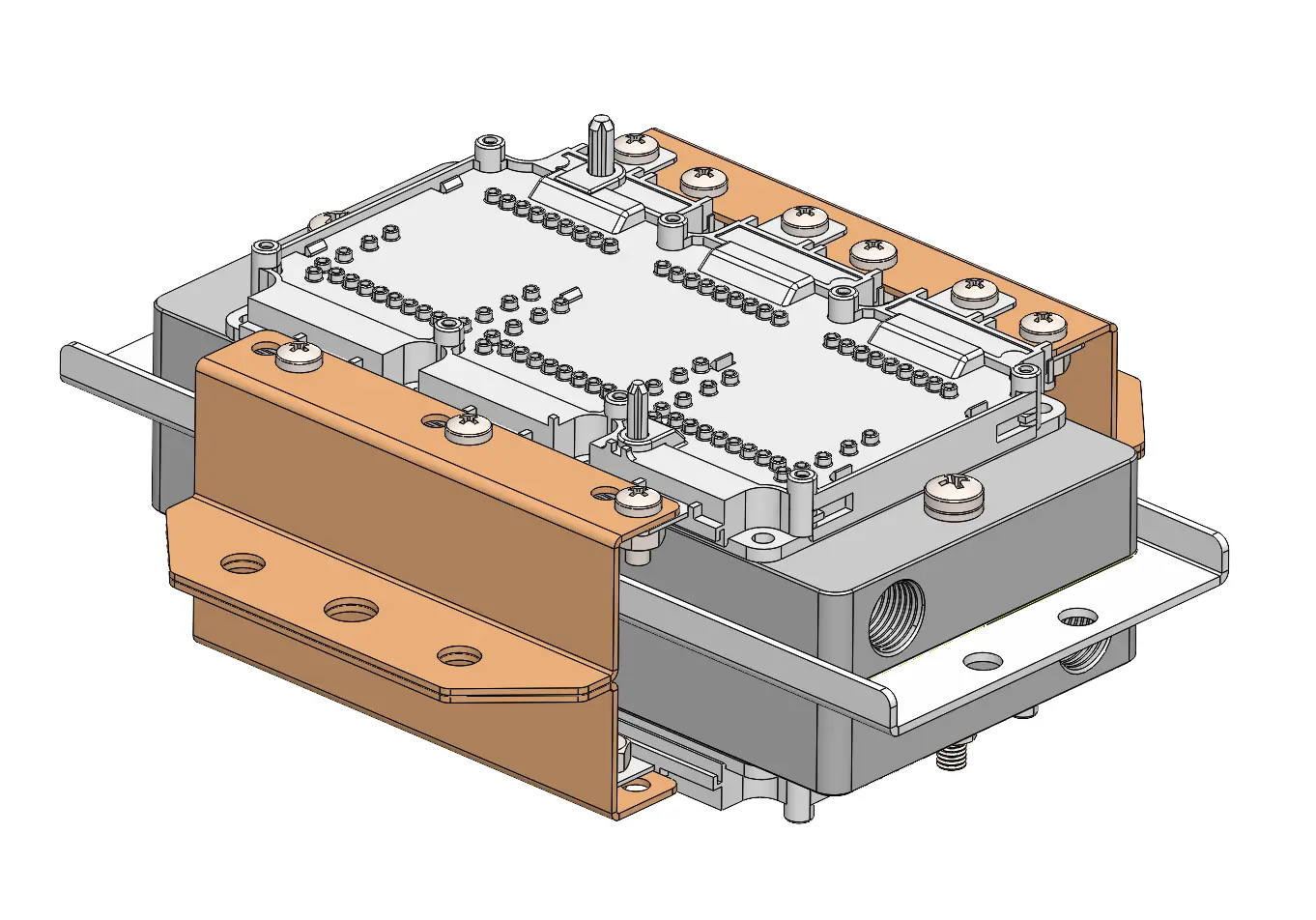

While the resistor’s ceramic body provides excellent electrical performance, its slow heat dissipation requires thoughtful thermal design in demanding applications. For dense or frequent pulse sequences, the use of forced air cooling, liquid cooling, or external heat sinks is recommended to maintain safe operating temperatures and ensure consistent performance.

Typical use cases include:

- Braking resistors in rail and industrial motor drives

- Snubber circuits in high-voltage inverters and converters

- Surge suppression modules in HVAC and power distribution systems

- Test loads for high-energy validation in R&D and manufacturing

Environmental and Storage Considerations

The resistor operates reliably in ambient temperatures from –40°C to +125°C, with relative humidity up to 90% and atmospheric pressure between 86–106 kPa. For long-term storage, units should be kept in dry, non-corrosive environments. If stored for extended periods, a pre-use bake-out at 100–130°C for 8+ hours is recommended to eliminate moisture absorption and restore insulation performance.

Conclusion

This high-energy pulse resistor stands out as a versatile, rugged solution for engineers seeking a dependable energy absorption resistor or surge resistor in high-voltage, high-reliability systems. Its combination of high insulation strength, surge resilience, and controlled thermal behavior makes it an essential component in modern power electronics—provided it is integrated with appropriate thermal management strategies. Whether used in industrial braking, renewable energy, or high-voltage testing, it delivers consistent performance under the most demanding transient conditions.