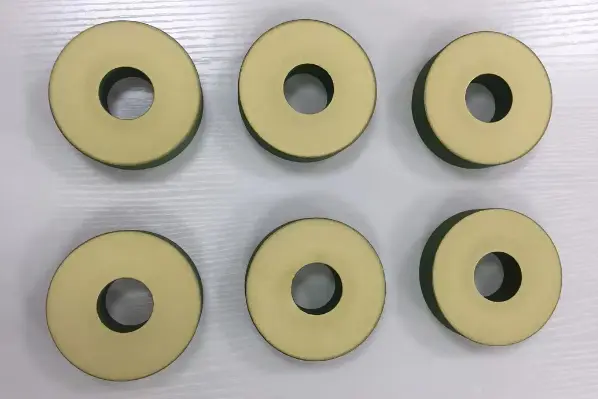

High energy ceramic resistors are resistors made from ceramic materials that exhibit excellent thermal stability and electrical performance. Their finished products can operate reliably in extreme environments and are widely used in electronic components to effectively control current and voltage.

Application Fields

These resistors are widely used in industries such as automotive, aerospace, and other fields with strict environmental requirements. Applications like high-frequency circuits and power amplifiers have very high performance demands for resistors, ensuring the safe and stable operation of equipment.

Product Advantages

High energy ceramic resistors possess high-temperature resistance, exceptional mechanical strength, and a low temperature coefficient, allowing them to maintain good performance over extended periods of operation. Additionally, their long lifespan and compact design make them a preferred choice in the market.

The production process of high energy ceramic resistors can be divided into several stages, including material preparation, ball milling, granulation, shaping, sintering, and gold spraying. Each stage has its unique importance, ensuring the quality of the final product.

Each process step is crucial to the performance of the final resistor. Precise control of each step is necessary to ensure that the high energy ceramic resistors meet design specifications. Factors such as the selection of raw materials, uniformity of mixing, and sintering temperature can all affect the quality of the final product.

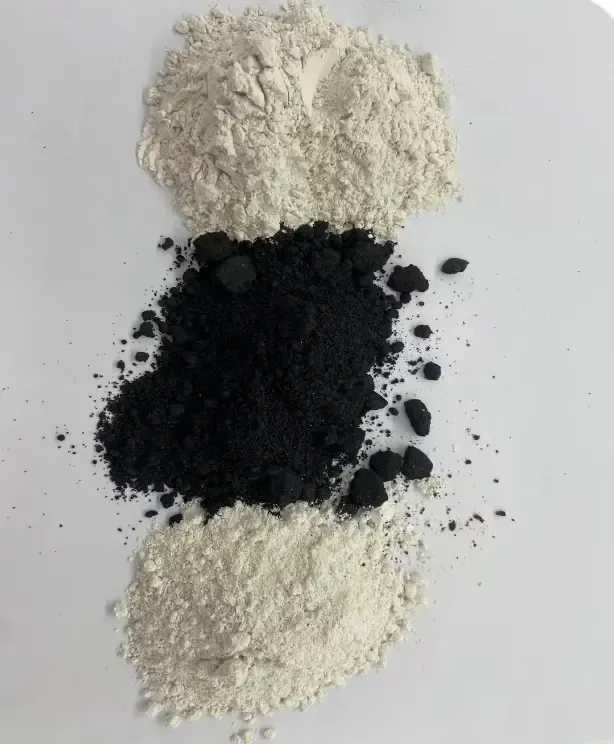

Ceramic Powder

Ceramic powder is the main component of high energy ceramic resistors, and its quality directly affects the performance of the final product. Depending on the different resistance characteristics and application requirements, suitable ceramic powders, such as alumina or other transition metal oxides, are selected.

Binders

Binders are materials used to connect the ceramic powders and enhance the stability of the formed body. Commonly used binders must possess good thermal stability and chemical compatibility to prevent reactions with the ceramic materials during sintering.

Importance of Accurate Weighing

Accurate weighing of each raw material is crucial, as even slight variations in the mixture can lead to instability in resistance characteristics. The selected materials need to be precisely calculated according to the resistor design standards to ensure the accuracy of the resistance value.

Mixing Method

The mixing process typically employs mechanical stirring or high-energy ball milling to ensure that various raw materials are thoroughly blended. This process helps eliminate agglomerates in the materials, thereby improving the quality of subsequent processes.

Ensuring Material Quality

Only through effective mixing methods can the performance indicators of the ceramic resistors be evenly distributed, avoiding local inconsistencies or defects, and ensuring the overall high quality of the product.

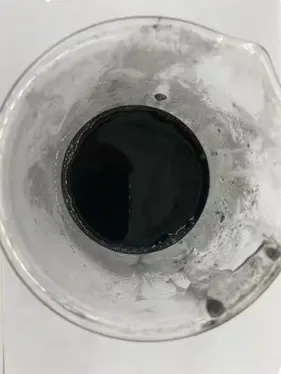

The Role of Ball Mills

Ball mills are important equipment used for grinding ceramic materials, effectively reducing larger particles into fine, uniform particles. Through the collisions and friction between objects, they reduce the particle size of the materials, facilitating smoother subsequent processes.

Material Fineness*

The fineness of the ground material significantly impacts the sintering characteristics of resistors. Finer particles can bond more closely during sintering, enhancing the strength and stability of the product, and ensuring that the final electrical performance meets the standards.

The uniformity of the material determines the smooth progression of the forming and sintering processes. The higher the uniformity of the raw material particles, the greater the density and consistency of the formed body, which contributes to the enhancement of resistor performance.

Uniform materials can effectively reduce defects during the forming process and improve the yield. It is essential to strictly control the grinding time and process parameters to ensure the quality consistency of the final product.

During the granulation process, the material needs to form particles of uniform size to ensure increased density during sintering and facilitate the bonding between ceramic particles. This directly affects the mechanical strength and electrical performance of the resistor.

Appropriate particle size and uniform distribution can enhance the bonding force during the sintering process, thereby increasing the density of the material after sintering, reducing porosity, improving pressure resistance, and ultimately enhancing the overall performance of the resistor.

The Role of High-Temperature Furnace

The high-temperature furnace plays a critical role during the sintering stage. By heating the formed body in a high-temperature environment, it allows the ceramic particles to melt and bond, enhancing the mechanical strength and electrical performance of the material.

Enhancement of Material’s Mechanical Strength

The sintering process not only improves the strength of the material but also allows for the adjustment of resistance values and temperature coefficients, providing a more solid foundation for subsequent gold plating and packaging, ensuring the long-term use of the resistor.

The metal films used in gold plating are typically made of gold or silver, as these metals provide excellent conductivity and ensure that the electrodes of the resistor have outstanding performance. A proper selection of the metal film can enhance the overall performance of the resistor.

The gold plating layer not only needs to have good conductivity but should also possess long-lasting wear resistance to withstand the wear caused by prolonged use. Fine control of the gold plating process is essential to ensure the reliability of the electrodes.