Composition and Application of Water-Cooled Transformers

I. Composition of Water-Cooled Transformers

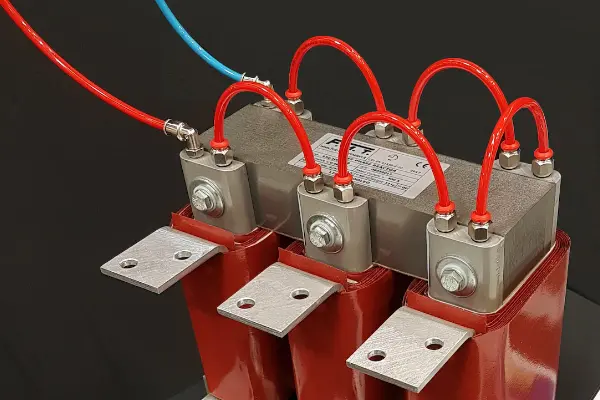

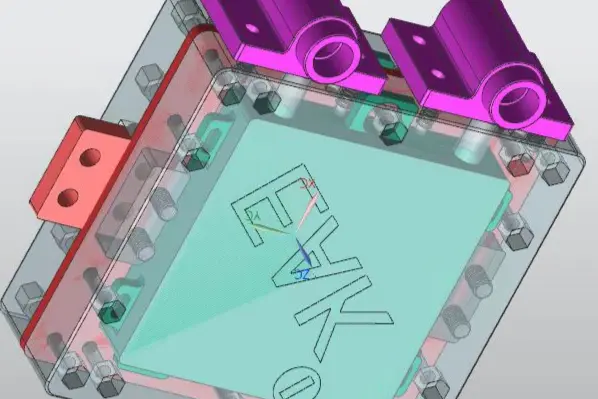

A water-cooled transformer is a type of transformer that effectively reduces temperature and improves operational efficiency through a water cooling system. Its main components include:

1. Transformer Core: Made of high-permeability materials, responsible for the conversion and transmission of electrical energy. 2. Windings: Includes high-voltage and low-voltage windings, used for the input and output of current. 3. Insulating Medium: Typically uses insulating oil or insulating materials to ensure electrical insulation performance. 4. Water Cooling System: Composed of water pipes, cooling devices, and water pumps, this system circulates water to carry away the heat generated by the transformer, maintaining the equipment at an appropriate operating temperature. 5. Enclosure: Protects internal components from external environmental influences, ensuring stable operation of the equipment.

II. Applications of Water-Cooled Transformers

Water-cooled transformers, with their excellent heat dissipation performance and efficient electrical energy transmission capabilities, are widely used in various fields:

1. Power Industry: In power plants and substations, water-cooled transformers can handle higher loads, ensuring that equipment operates stably for extended periods under high-temperature conditions. 2. Metallurgical Industry: Used in high-energy-consuming smelting equipment, water-cooled transformers provide reliable power support, enhancing the efficiency and safety of metallurgical processes. 3. Data Centers: With the increasing demand for data processing, water-cooled transformers can meet high power requirements, ensuring the stability of high-density power systems in data centers. 4. Renewable Energy: In wind and solar power generation systems, water-cooled transformers can improve system efficiency and promote the use of renewable energy.

III. Conclusion

Water-cooled transformers, with their efficient heat dissipation capabilities and stable electrical energy conversion performance, have become an indispensable component in modern power systems and industrial equipment. As industrial and technological advancements continue, water-cooled transformers are expected to demonstrate their potential and advantages in more fields.