Solid Oxide Fuel Cells (SOFCs) are among the most efficient clean energy technologies, converting hydrogen, natural gas, or biogas directly into electricity with combined heat and power (CHP) efficiencies up to 60%. Operating at 600–1000°C, SOFCs demand materials that combine high thermal stability, corrosion resistance, and excellent electrical conductivity—a role increasingly filled by ultra-low-resistivity silicon carbide (SiC) conductive ceramics.

Engineered to achieve a remarkable resistivity as low as 10⁻⁷ Ω·m through nitrogen doping or advanced sintering techniques, SiC now rivals metals like aluminum (≈10⁻⁸ Ω·m) in conductivity—while offering superior durability in harsh SOFC environments.

1. SiC in SOFC Interconnects: Minimizing Ohmic Losses, Maximizing Efficiency

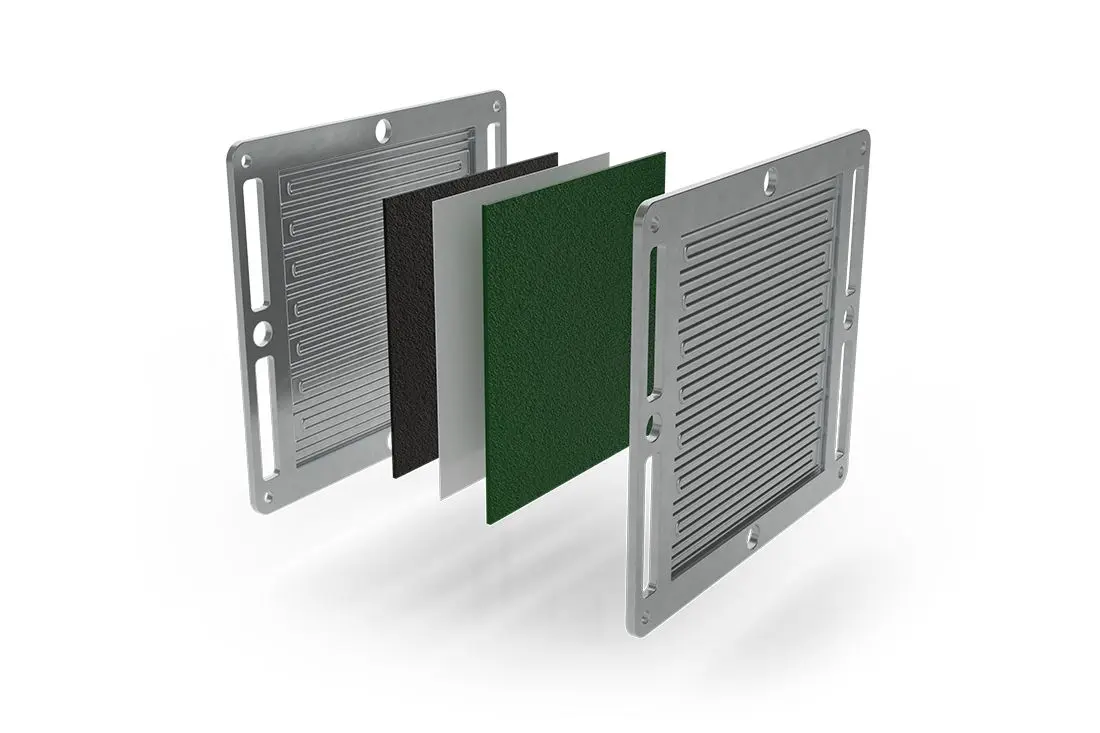

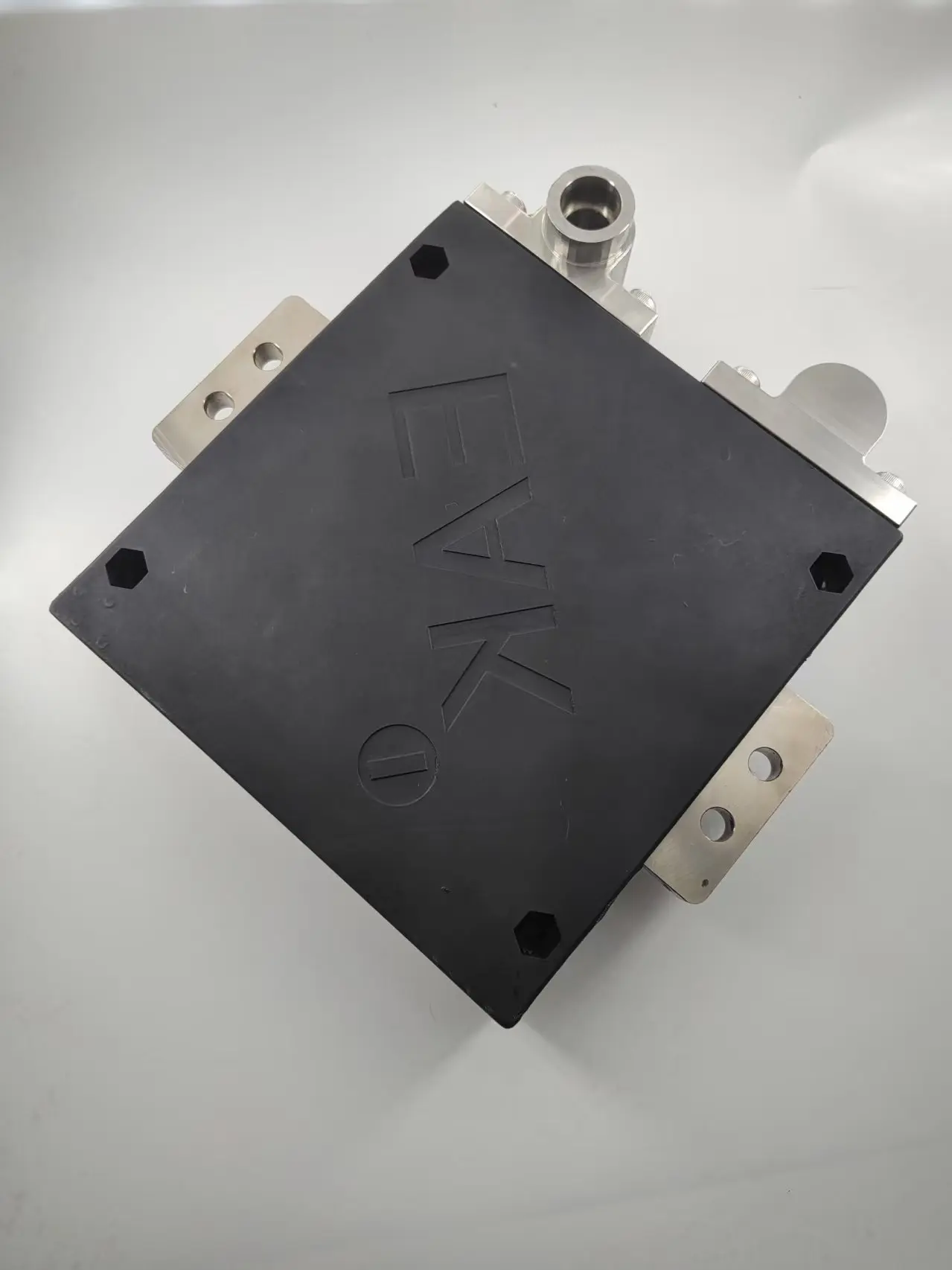

Interconnects are critical components that electrically link individual SOFC cells in a stack while separating fuel and oxidant gases. Traditional materials—such as ferritic stainless steels or lanthanum chromite (LaCrO₃)—suffer from:

- High oxidation rates

- Contact resistance >0.1 Ω·cm² at 800°C

- Voltage drops up to 20% in stack performance

In contrast, low-resistivity SiC-based composites (e.g., Ti–Si–C systems) deliver:

- Area-specific resistance (ASR) < 0.05 Ω·cm² — a 50% improvement

- Oxidation resistance: mass gain <0.01 mg/cm² after 1000h at 800°C

- Thermal conductivity >100 W/m·K for superior heat management

- Stable conductivity of 200–300 S/cm at 700–800°C

- Coefficient of thermal expansion (CTE ≈4–5 × 10⁻⁶/K), closely matching YSZ electrolytes to prevent delamination

These properties enable SOFC stacks to sustain power densities >1 W/cm² over 5,000 hours, with lifespans exceeding 40,000 hours—especially vital for intermediate-temperature SOFCs (600–800°C).

2. SiC Cermets in SOFC Anodes: Enhanced Catalysis & Fuel Flexibility

In anode applications, SiC is integrated into cermets (ceramic-metal composites), often blended with Ni or Cu, to create highly conductive 3D networks:

- Resistivity reduced from ~10⁻² Ω·m (Ni-YSZ) to 10⁻⁷ Ω·m with 10–20 wt% SiC nanoparticles

- Polarization resistance lowered by 30–40%

- Suppressed carbon deposition during hydrocarbon reforming

- Tolerance to 10 ppm H₂S for >100 hours—resisting sulfur poisoning

Recent studies show SiC-ZnO composite anodes achieving:

- Ionic conductivity: 0.12 S/cm at 600°C

- Peak power density: 270 mW/cm² — double that of conventional Ni-based anodes

In low-temperature variants, LiSiC-SDC (samarium-doped ceria) electrolytes doped with SiC reach:

- Open-circuit voltage (OCV) >1.0 V

- Current density >1.5 A/cm² at 500°C

This opens doors for portable and compact SOFC systems.

3. Performance Benefits & Commercial Outlook

Integrating 10⁻⁷ Ω·m SiC conductive ceramics into SOFCs delivers measurable system-level advantages:

- Ohmic losses reduced to just 5–10% of total cell resistance

- Thermal shock resistance: survives >50 cycles (200°C ↔ 900°C)

- 15–20% higher overall efficiency vs. chromite-based interconnects

- Stack performance: 0.8–1.2 W/cm² at 750°C with <5% degradation over 10,000 cycles

- Scalable manufacturing via CVD, spark plasma sintering, and emerging 3D-printed SiC foams

While challenges remain—such as phase stability above 900°C—ongoing R&D is rapidly addressing these.

The Future: SiC as a Cornerstone of SOFC Commercialization

With the global SOFC market projected to reach $10 billion by 2030, driven by demand from data centers, distributed power, and zero-emission vehicles, low-resistivity SiC conductive ceramics are positioned to accelerate SOFC adoption. Their unique blend of metal-like conductivity, ceramic robustness, and fuel flexibility makes them indispensable for next-generation clean energy systems.