EAK presents a groundbreaking design in high-performance liquid-cooled resistor and water-cooled resistor technology, engineered to meet the most demanding industrial and energy applications. Our new generation of water-cooled resistors combines advanced thermal management with superior electrical performance, making it ideal for use in harsh environments where reliability and precision are critical.

High Precision and Low Temperature Coefficient

This innovative liquid-cooled resistor offers an impressive resistance range from 10 milliohms to 32 ohms, with tolerance options ranging from 1% to 10%. Designed for stability, the resistor features an ultra-low temperature coefficient as low as 25 PPM/°C, ensuring minimal resistance drift under varying operating conditions. This level of accuracy makes it suitable for precision control systems, regenerative braking, and high-frequency power conversion applications.

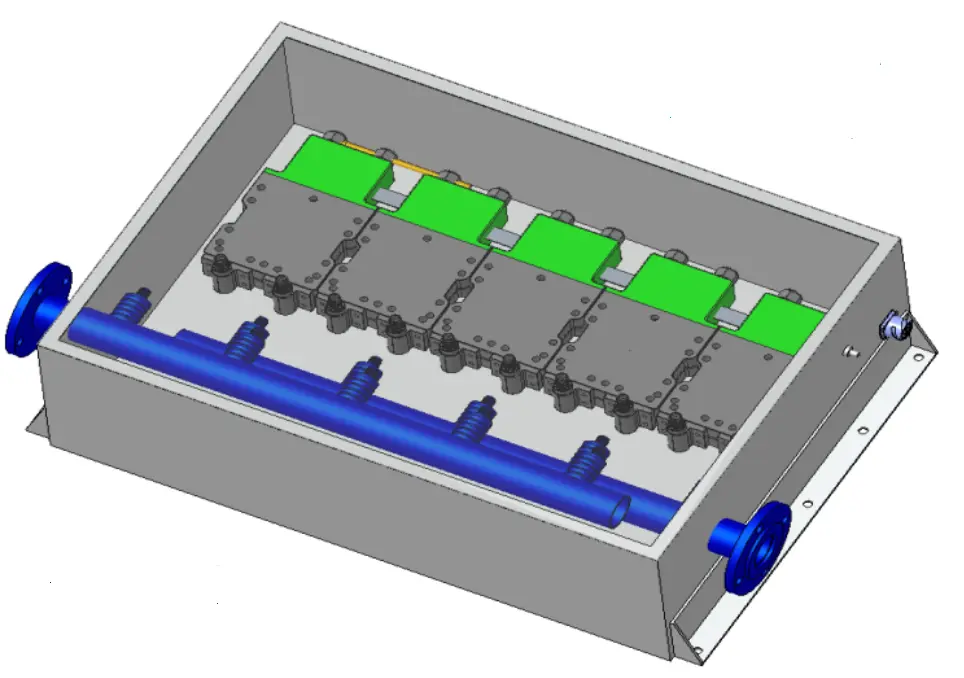

Dual-Sided Water Cooling and Robust Thermal Design

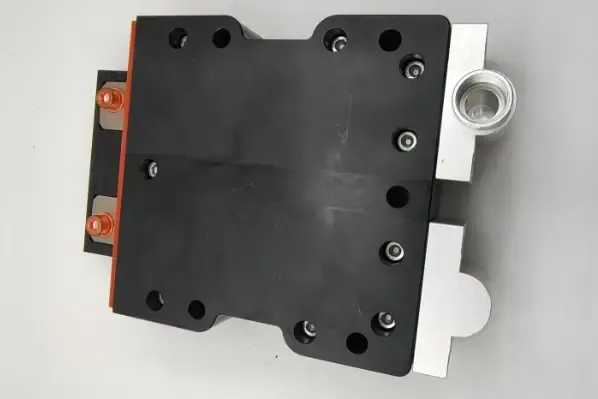

Incorporating cutting-edge dual-side water cooling technology compatible with IGBT modules, this water-cooled resistor ensures efficient heat dissipation even under extreme load conditions. The optimized internal water channel design enhances thermal conductivity while maintaining structural integrity, allowing operation in the harshest environments without compromising performance or safety.

Ceramic Insulation and High Voltage Withstanding Capability

To ensure electrical safety and long-term reliability, the resistor undergoes advanced ceramic insulation treatment. This process guarantees an insulation withstand voltage of over 1500V, offering excellent dielectric strength and protection against electrical breakdowns. The robust insulation also supports safe and stable operation in high-voltage applications up to 110kV.

Leak-Proof Welding and Vibration Resistance

Built with high-end welding techniques, the resistor housing is fully sealed to prevent liquid leakage, ensuring safe operation in continuous high-power scenarios. Its one-piece encapsulation design provides exceptional mechanical strength and vibration resistance, making it ideal for mobile and transportation applications such as electric vehicles, rail transit, and marine systems.

Water Cooled Resistor

Water Cooled Resistor

Ultra-Low Inductance and High Current Handling

The resistor core is specially designed with ultra-low inductance characteristics, minimizing parasitic effects and ensuring clean, fast response in high-frequency switching circuits. Each unit can handle ultra-high currents up to 1000A and deliver two 10kW resistive paths through internal series-parallel configurations. This modular yet compact structure enables efficient power distribution while maintaining excellent electrical isolation between water and electricity.

Ideal for Demanding Industrial Applications

Thanks to its combination of high power handling, precise resistance control, and rugged construction, this liquid-cooled resistor is widely applicable across industries including renewable energy systems, industrial motor drives, EV charging infrastructure, grid energy storage, and more. Whether used in dynamic braking systems, DC link filtering, or pulse power applications, EAK’s water-cooled resistor delivers unmatched performance and durability.

Conclusion

EAK’s new-generation water-cooled resistor sets a new standard in high-power resistor design. With its dual-side cooling capability, high-precision resistance values, advanced insulation, and robust structural design, it is the ideal solution for engineers seeking reliable, high-efficiency thermal and electrical management. As industries continue to demand higher performance and greater efficiency, EAK remains at the forefront of innovation in liquid-cooled resistor technology.