In the world of high-power electronics, thermal management and electrical performance are critical. That’s where the EAK Liquid-Cooled Resistor stands out—engineered to deliver reliable, efficient, and stable performance in the most demanding environments. Whether you’re testing electric motors, managing regenerative energy, or operating in high-frequency power systems, EAK’s advanced liquid-cooled resistor technology offers a superior alternative to traditional air-cooled or metal-film resistors.

Designed for power ranges from 10kW to 50kW, the EAK liquid-cooled resistor is built for high-power applications in industries such as renewable energy, rail transit, industrial automation, and marine power systems. Its ultra-low inductance design ensures minimal electromagnetic interference and voltage spikes, making it ideal for use with modern power semiconductors like IGBTs and SiC MOSFETs. This “nearly non-inductive” characteristic enables faster response times and smoother operation in dynamic load and braking scenarios.

At the heart of the EAK resistor is a proprietary ceramic resistive core made from silicon carbide (SiC) and silicon nitride (Si₃N₄). Unlike conventional metal resistors that degrade under extreme heat, this advanced ceramic material maintains exceptional mechanical strength, dimensional stability, and consistent conductivity—even at temperatures exceeding 1,000°C in oxidizing or inert atmospheres. By leveraging hole conduction theory and introducing tailored conductive phases, EAK achieves precise resistivity control from 10⁻⁵ Ω·m to 500 Ω·m, allowing customization for a wide range of system impedance requirements.

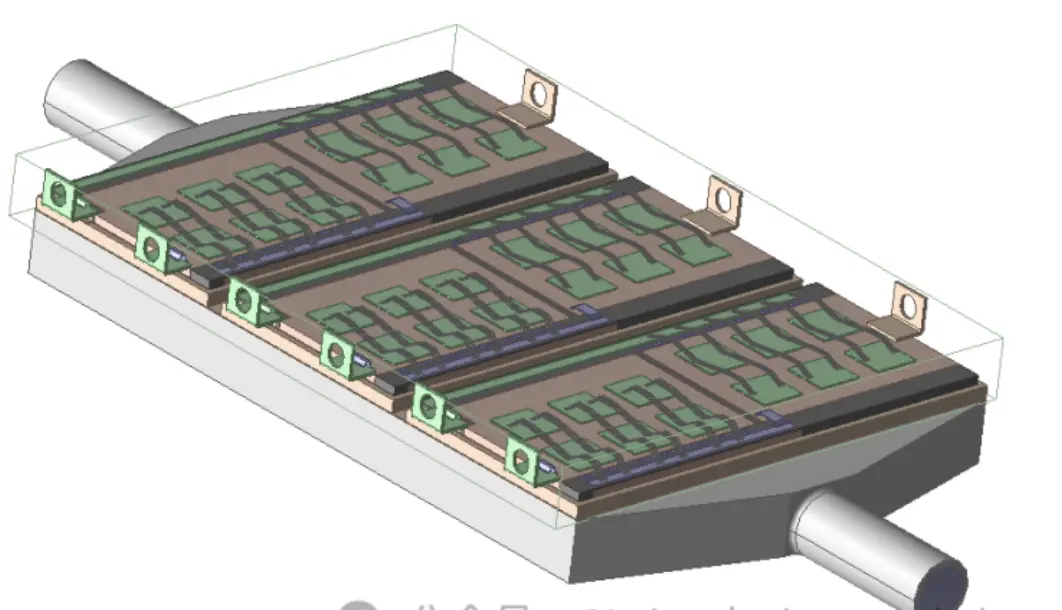

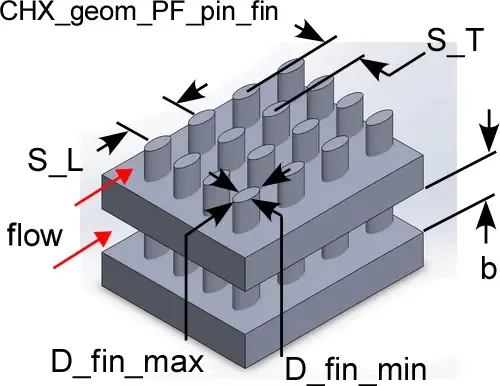

But performance isn’t just about materials—it’s also about thermal management. The EAK liquid-cooled resistor features a cutting-edge PIN-FIN cooling fin structure combined with a dual-sided water-cooling design. This innovative approach maximizes surface area for heat exchange and ensures rapid, uniform heat dissipation from both sides of the core. The result? Exceptional thermal efficiency, reduced hotspots, and sustained operation under full load—critical for long-term reliability in industrial environments.

Complementing this advanced cooling system is a diamond insulation layer, which provides both ultra-high electrical isolation (over 20 kV/mm) and outstanding thermal conductivity (up to 1000 W/mK). This unique combination minimizes thermal resistance while ensuring safety and durability, even under high-voltage and high-temperature conditions.

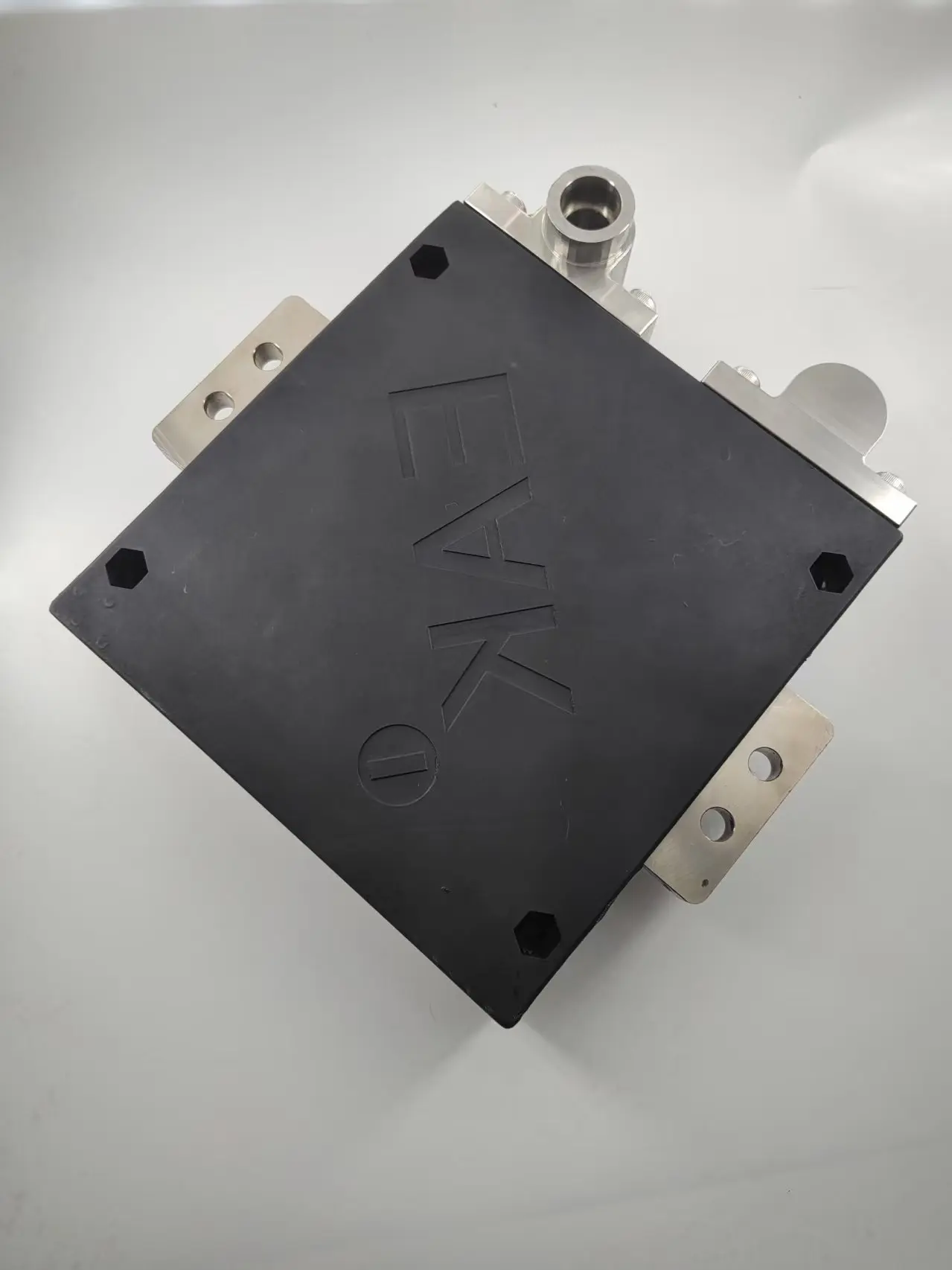

The compact, high-power-density design of the EAK liquid-cooled resistor makes it ideal for space-constrained applications where performance cannot be compromised. Its robust construction resists vibration, corrosion, and thermal cycling, making it suitable for use in harsh environments such as test benches, energy recovery systems, and dynamic braking units.

What truly sets EAK apart is its commitment to innovation and customization. Every liquid-cooled resistor can be tailored to specific resistance values, cooling interface configurations, and monitoring capabilities—ensuring seamless integration into your system.

As industries move toward higher efficiency, smaller footprints, and greener technologies, the demand for intelligent, high-performance power components continues to grow. The EAK liquid-cooled resistor meets this demand head-on, combining advanced materials, superior thermal design, and proven reliability.